Combustible gas explosion testing device in explosion venting space

A technology of explosion test and test device, which is applied in the direction of material explosiveness, etc., can solve the problems such as the inability to realize the explosion test of combustible gas, and the inability to study the problem of gas explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

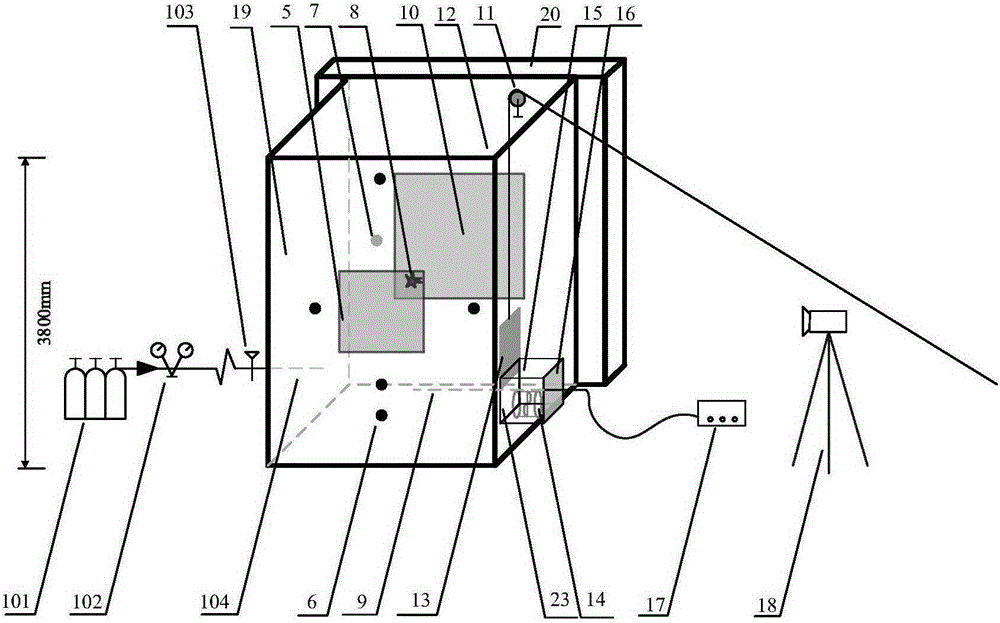

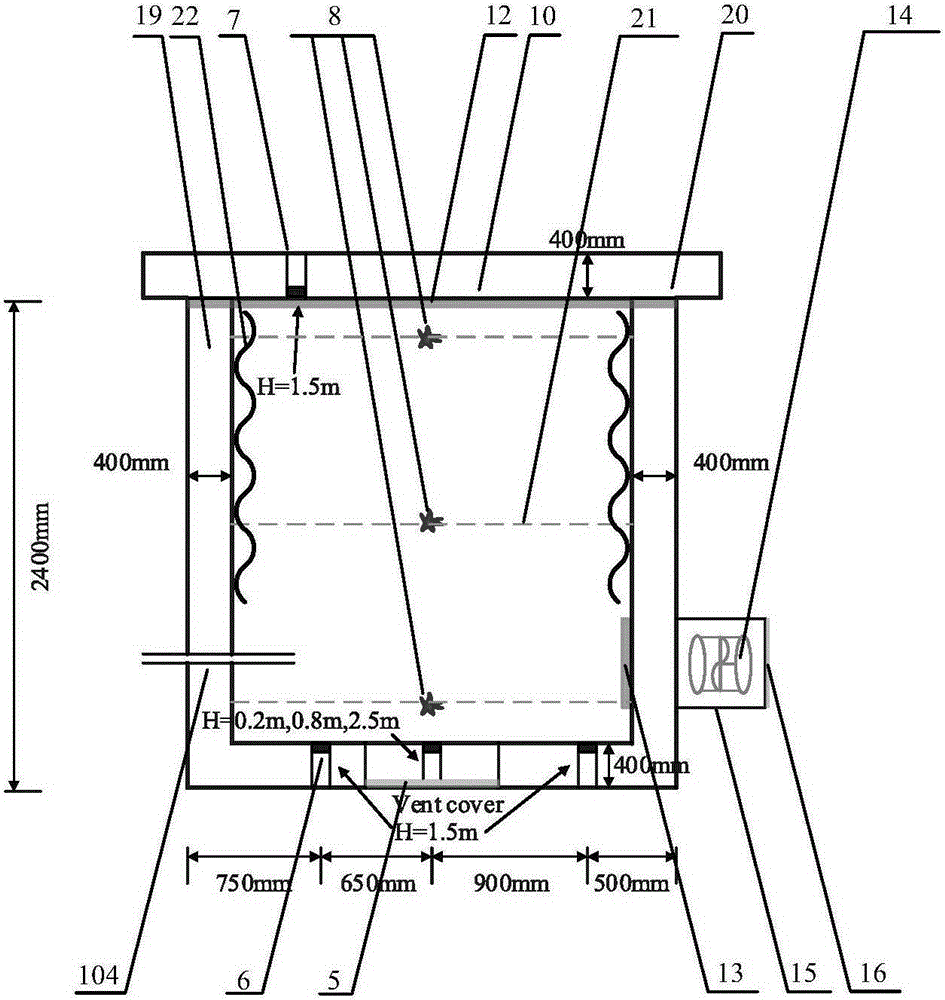

[0015] Such as figure 1 and 2 As shown, the combustible gas venting space explosion test device of the present invention includes a gas source 1, pressure sensors 6, 7, an infrared gas analyzer 17, a high-speed camera 18 and an airtight chamber 19,

[0016] The airtight chamber 19 is a full-scale reinforced concrete structure, and its rear side wall is a full steel plate structure. On the front side wall of the airtight chamber 19, there are front explosion relief holes 5 communicating with the outside of the room, and the front explosion relief holes 5 Explosion venting materials are installed inside, and a rear explosion venting hole 10 communicating with the outside of the room is provided on the rear side wall of the airtight chamber 19. Explosion venting materials are installed in the rear explosion venting hole 10, and on one side of the airtight chamber 19 An airtight cabinet 15 is arranged outside the wall, and the airtight cabinet 15 communicates with the airtight ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com