A spirometry device

A measuring device and vital capacity technology, which is applied in the field of vital capacity measurement, can solve problems such as difficulty in ensuring the accuracy of measurement results, low intrapulmonary pressure, and adverse effects on measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

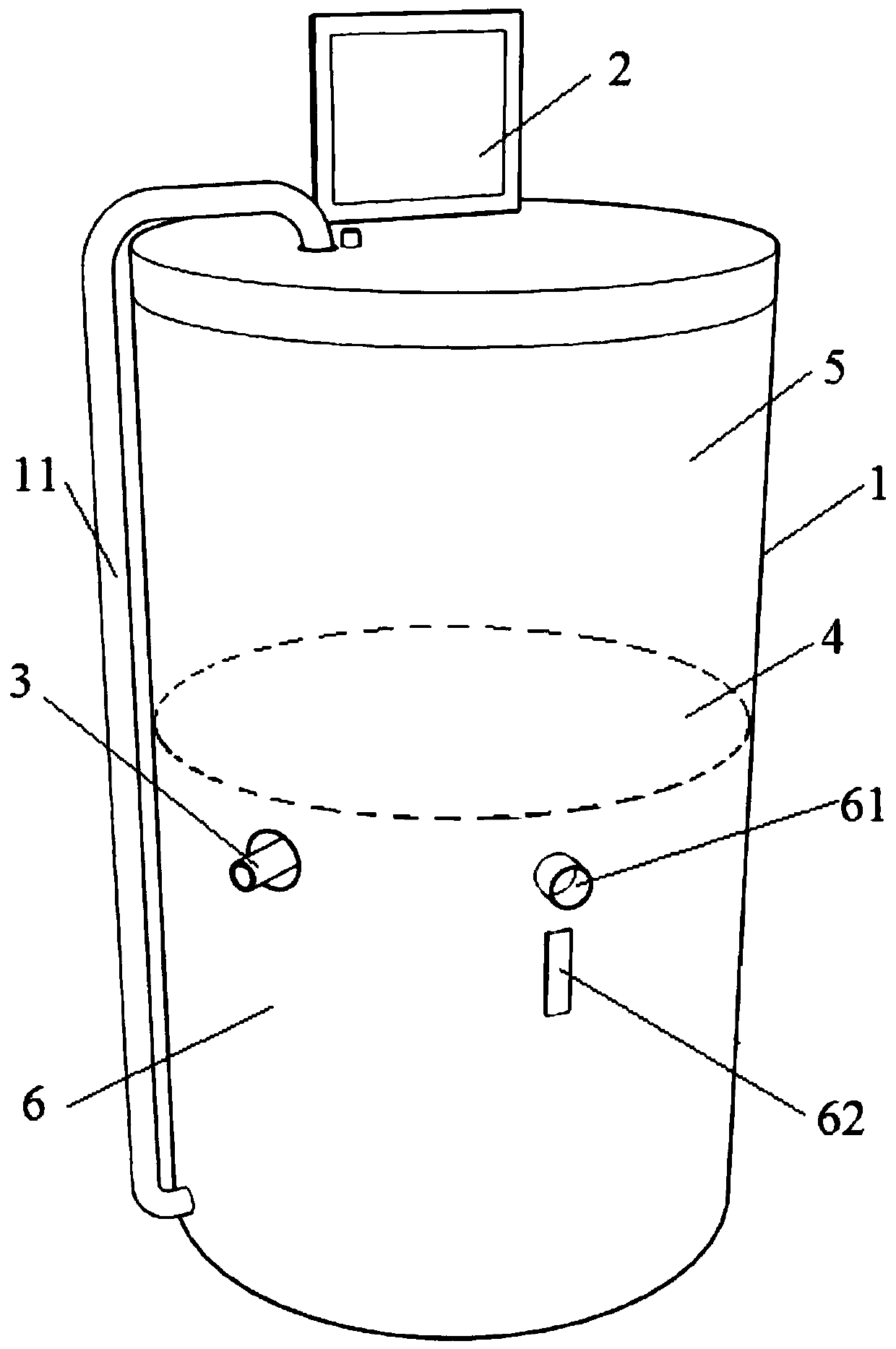

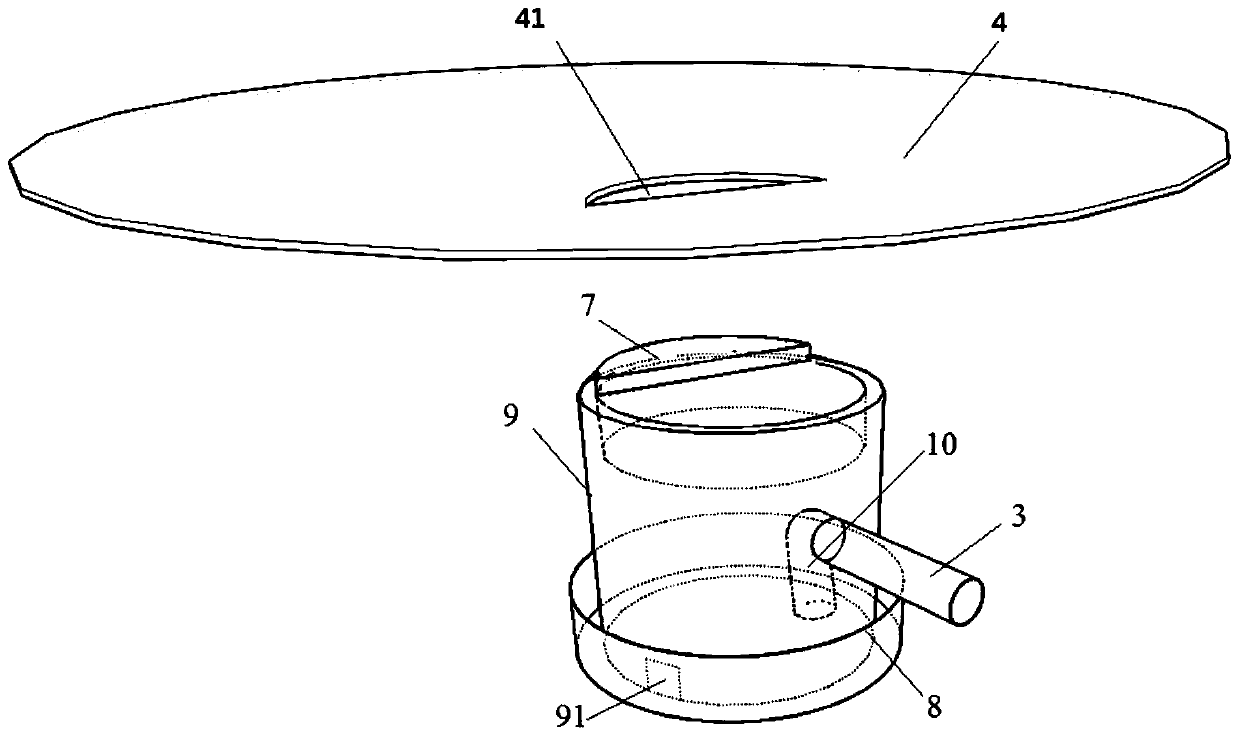

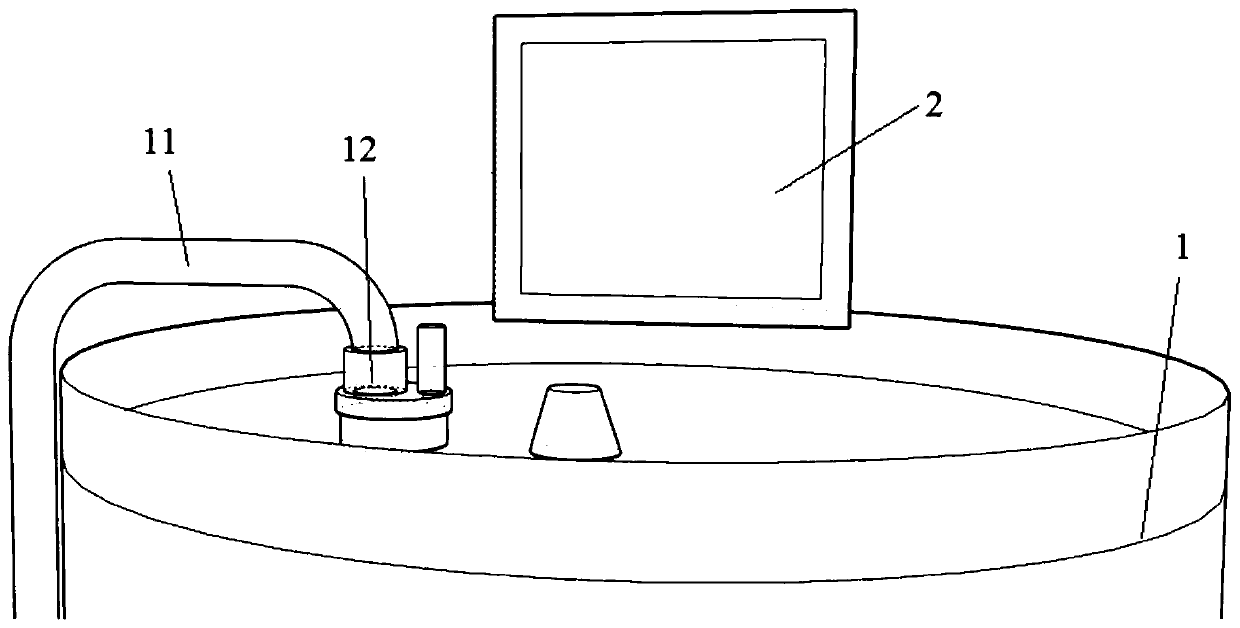

[0018] Embodiment one: if Figure 1-Figure 3 As shown, a vital capacity measuring device includes a box body 1, a pumping assembly, a radar water level measuring instrument, a controller, a display screen 2, a drainage assembly and an air guide tube 3; the radar water level measuring instrument and the display screen 2 are respectively connected to the controller, A partition 4 is arranged inside the box body 1, and the partition plate 4 divides the inside of the box body 1 into a measurement chamber 5 and a water storage chamber 6. The measurement chamber 5 is located above the water storage chamber 6, and the side wall of the water storage chamber 6 is provided with The water injection port 61, the partition plate 4 is provided with the opening 41 for communicating with the measuring chamber 5 and the water storage chamber 6; Pumped into the measurement chamber 5, the drainage assembly includes a sleeve 7, a water tank 8 and a first electric control valve 9, the sleeve 7 is ...

Embodiment 2

[0019] Embodiment two: if Figure 1-Figure 3As shown, a vital capacity measuring device includes a box body 1, a pumping assembly, a radar water level measuring instrument, a controller, a display screen 2, a drainage assembly and an air guide tube 3; the radar water level measuring instrument and the display screen 2 are respectively connected to the controller, A partition 4 is arranged inside the box body 1, and the partition plate 4 divides the inside of the box body 1 into a measurement chamber 5 and a water storage chamber 6. The measurement chamber 5 is located above the water storage chamber 6, and the side wall of the water storage chamber 6 is provided with The water injection port 61, the partition plate 4 is provided with the opening 41 for communicating with the measuring chamber 5 and the water storage chamber 6; Pumped into the measurement chamber 5, the drainage assembly includes a sleeve 7, a water tank 8 and a first electric control valve 9, the sleeve 7 is s...

Embodiment 3

[0021] Embodiment three: as Figure 1-Figure 3 As shown, a vital capacity measuring device includes a box body 1, a pumping assembly, a radar water level measuring instrument, a controller, a display screen 2, a drainage assembly and an air guide tube 3; the radar water level measuring instrument and the display screen 2 are respectively connected to the controller, A partition 4 is arranged inside the box body 1, and the partition plate 4 divides the inside of the box body 1 into a measurement chamber 5 and a water storage chamber 6. The measurement chamber 5 is located above the water storage chamber 6, and the side wall of the water storage chamber 6 is provided with The water injection port 61, the partition plate 4 is provided with the opening 41 for communicating with the measuring chamber 5 and the water storage chamber 6; pumped into the measurement chamber 5, the drainage assembly includes a sleeve 7, a water tank 8 and a first electric control valve 9, the sleeve 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com