Common voltage adjustment device and method

A common voltage and control device technology, applied in the direction of instruments, static indicators, etc., can solve the problems of manpower, material resources and time, low accuracy of public voltage, inaccurate data records, etc., to achieve accurate debugging, avoid errors, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

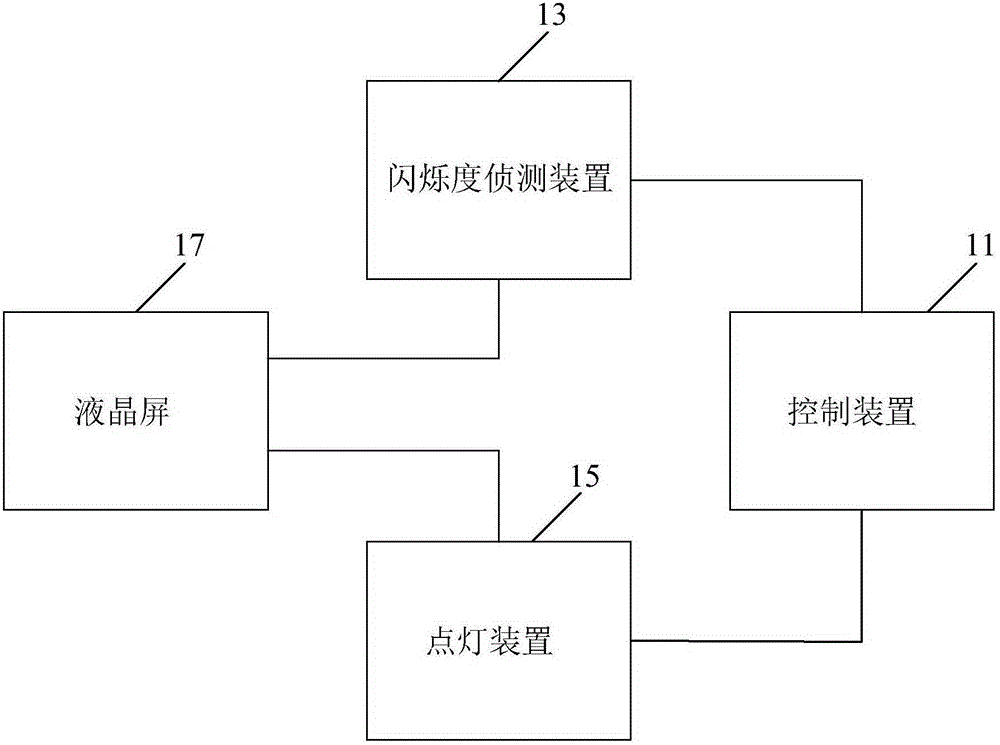

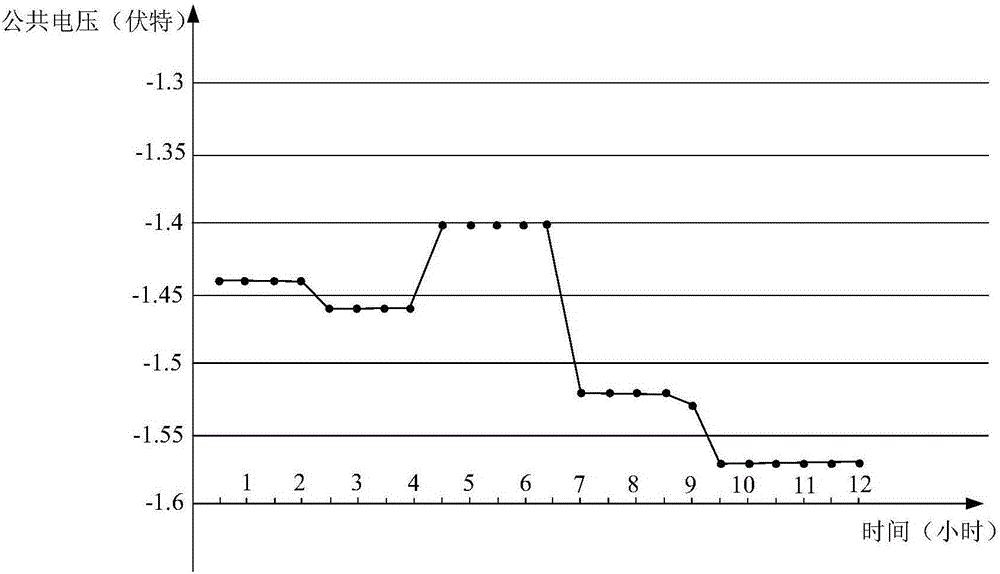

[0025] figure 1 It is a main structural block diagram of the common voltage debugging device provided by the first embodiment of the present invention. figure 2 It is a graph of the relationship between the optimal public voltage and time. Please refer to figure 1 and figure 2 , the public voltage debugging device includes: a control device 11 , a flicker detection device 13 connected to the control device 11 and a lighting device 15 . The flicker detection device 13 and the lighting device 15 are connected with the liquid crystal screen 17 .

[0026] The lighting device 15 is used to control and light the liquid crystal screen 17 according to the test picture provided by the control device 11 and the initial common voltage, so that the liquid crystal screen 17 displays the test picture under the initial common voltage, and the liquid crystal screen 17 lights up under the initial common voltage After a preset period of time, the liquid crystal screen 17 is controlled to ...

no. 2 example

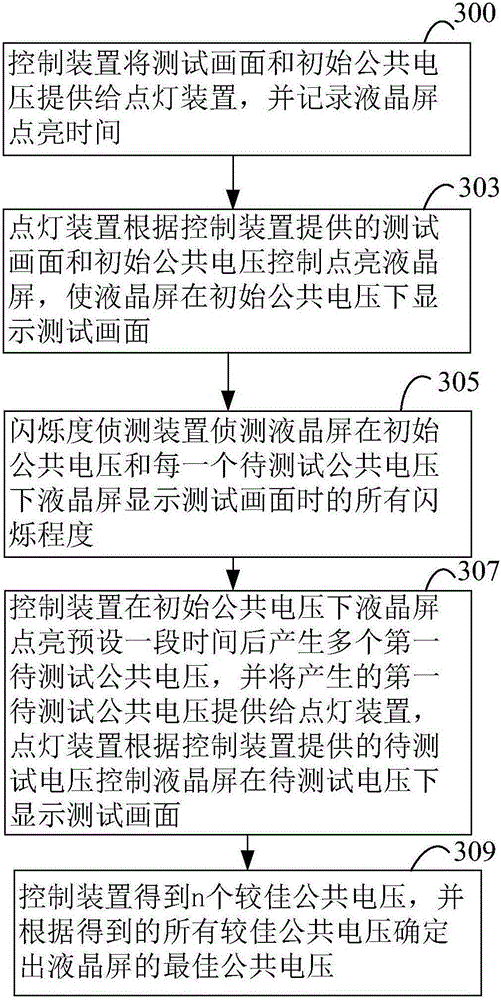

[0044] image 3 It is a flow chart of the steps of the common voltage debugging method provided by the second embodiment of the present invention. Please refer to image 3 , the public voltage debugging method of this embodiment includes the following steps 300-309.

[0045] Step 300, the control device provides the test pattern and the initial public voltage to the lighting device, and records the lighting time of the liquid crystal screen.

[0046] In step 303, the lighting device controls to light the liquid crystal screen according to the test picture provided by the control device and the initial common voltage, so that the liquid crystal screen displays the test picture under the initial common voltage.

[0047] In step 305, the flicker detection device detects all flicker levels of the liquid crystal screen when the liquid crystal screen displays a test picture under the initial common voltage and each common voltage to be tested, and provides all detected flicker lev...

no. 3 example

[0057] Figure 4 It is a flow chart of the steps of the public voltage debugging method provided by the third embodiment of the present invention. Figure 4 is in image 3 improved on the basis of Figure 4 and image 3 The difference is that Figure 4 Step 400 may also be included. Please refer to Figure 4 , the public voltage debugging method of the embodiment of the present invention may also include the following steps 300-309 and 400:

[0058] Wherein steps 300-309 are related to image 3 Same, no more details here.

[0059] Step 400, the initial common voltage is the initial preferred common voltage, then the control device generates a plurality of initial common voltages to be tested after providing the test pattern and the initial common voltage to the lighting device, and generates a plurality of initial common voltages to be tested. The voltage is provided to the lighting device, and the lighting device controls the liquid crystal screen to display the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com