Cable stabilizing and tilting prevention system and method used for high speed cable laser on-line ink-jet printing

An anti-falling and cable technology, which is applied to mark the direction of conductors/cables, etc., can solve the problems of low production efficiency and inconvenient adjustment, and achieve the effects of improving production efficiency, simple and convenient adjustment, and cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

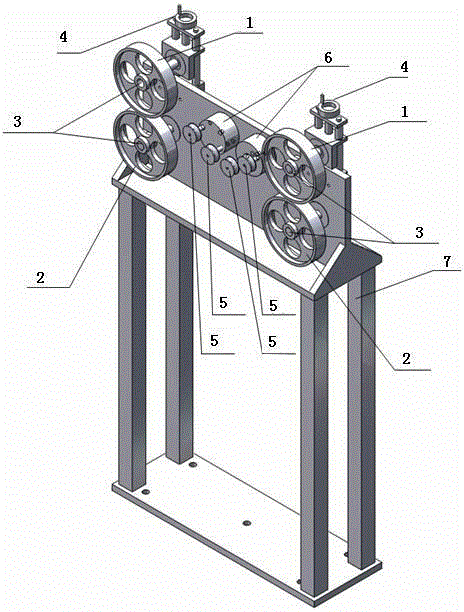

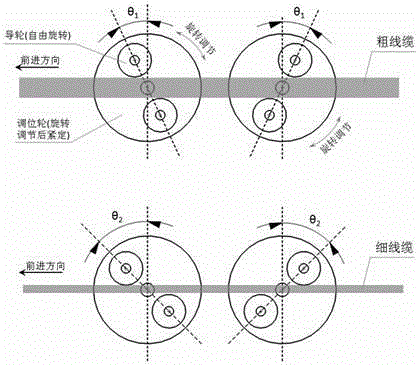

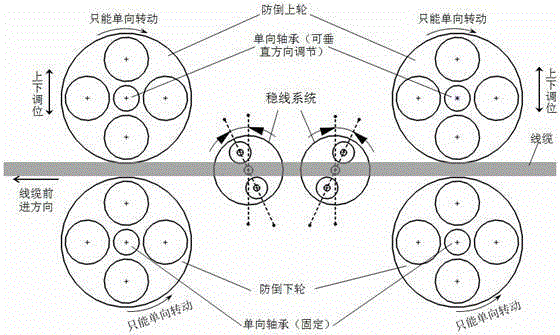

[0026] To provide a method and device for stabilizing the line and anti-falling of the laser online coding equipment in the high-speed cable production line, which can prevent the cable from swinging left and right, jumping up and down, and moving backwards on the production line. The anti-falling anti-rolling system includes the anti-falling wheel device, the thread stabilizing device and the bracket. The anti-falling wheel device includes two sets of anti-falling wheels, which are composed of the anti-falling upper wheel (1) and the anti-falling wheel (2). , located at both ends of the bracket, the anti-fall upper wheel (1) and the anti-fall lower wheel (2) are equipped with one-way bearings (3), the anti-fall upper wheel (1) can be adjusted up and down, and the anti-fall lower wheel (2) is fixed The height is adjusted by turning the height adjustment handle (4) to adjust the gap between the anti-falling upper wheel (1) and the anti-falling wheel (2). Two positioning wheels ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap