Method for producing motor vehicle door locks with a rolling surface as a locking part contour

A technology for locking components, motor vehicles, applied in the direction of lock applications, building locks, vehicle locks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

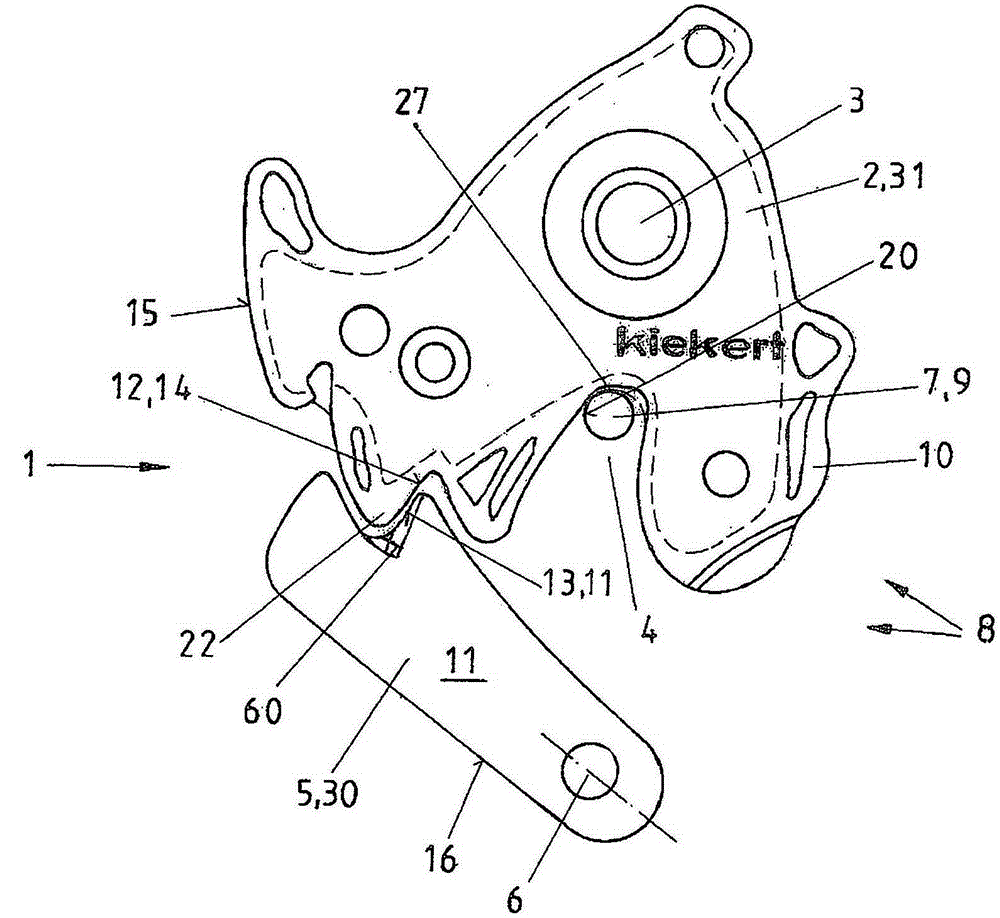

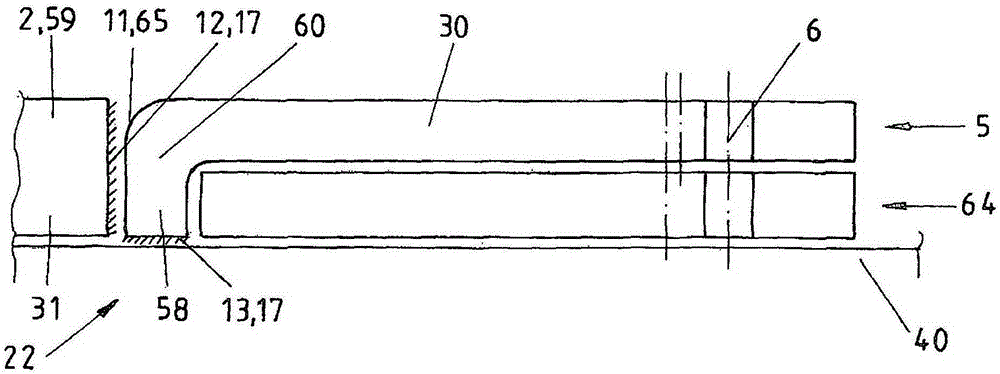

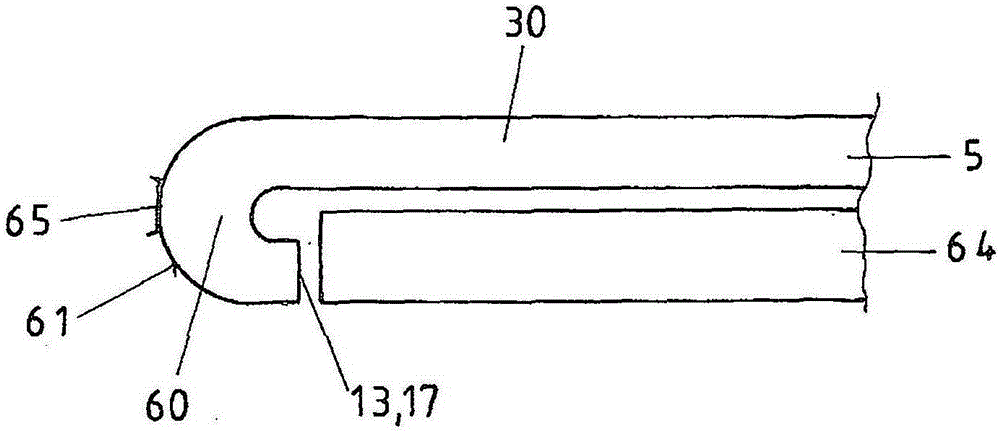

[0023] figure 1 A top view of a motor vehicle lock 1 is shown, in which a rotary locking fork 2 movable about an axis 3 surrounds a locking bow leg 9 of a locking bow (or lock catch) 7 . That is to say, the locked state of the motor vehicle lock 1 is reflected here, wherein the rotary locking fork 2 is fixed by the pawl 5 which can pivot around the pawl axis 6, that is to say, the motor vehicle lock 1 is only locked when the pawl 5 has been pivoted away ( This is achieved by the motor vehicle door handle (not shown here) and can only be opened again. The locking bow leg 9 moves on the rotary locking fork 2 via the receptacle 4 as far as the depth bottom 27 and thus ensures the locked state of the motor vehicle door, also not shown here, wherein the locking parts 30 , 31 ie the locking pawl 5 and the rotary The locking fork 2 is part of the motor vehicle door, while the locking bow 7 with the locking bow legs 9 is fastened to the body of the motor vehicle. The locking parts 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com