Contact part for a drive module, drive module and method for producing the contact part

A technology of contact parts and drive modules, which is applied in the direction of electric components, printed circuit manufacturing, and control/drive circuit connection, etc. It can solve the problems affecting the overall size of the drive module and expand the structural space, so as to improve EMV characteristics, reduce costs, Effect of saving plastic material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

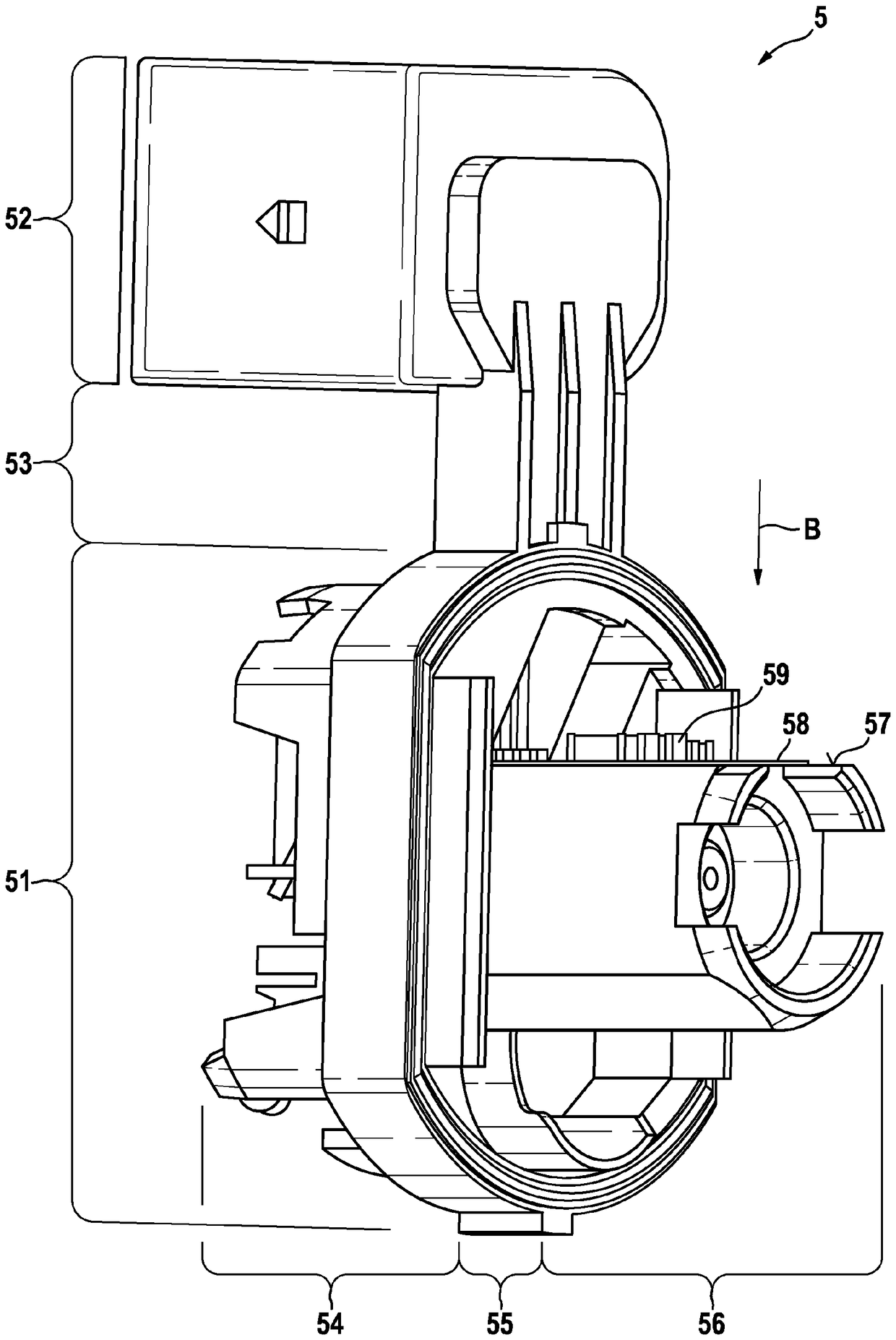

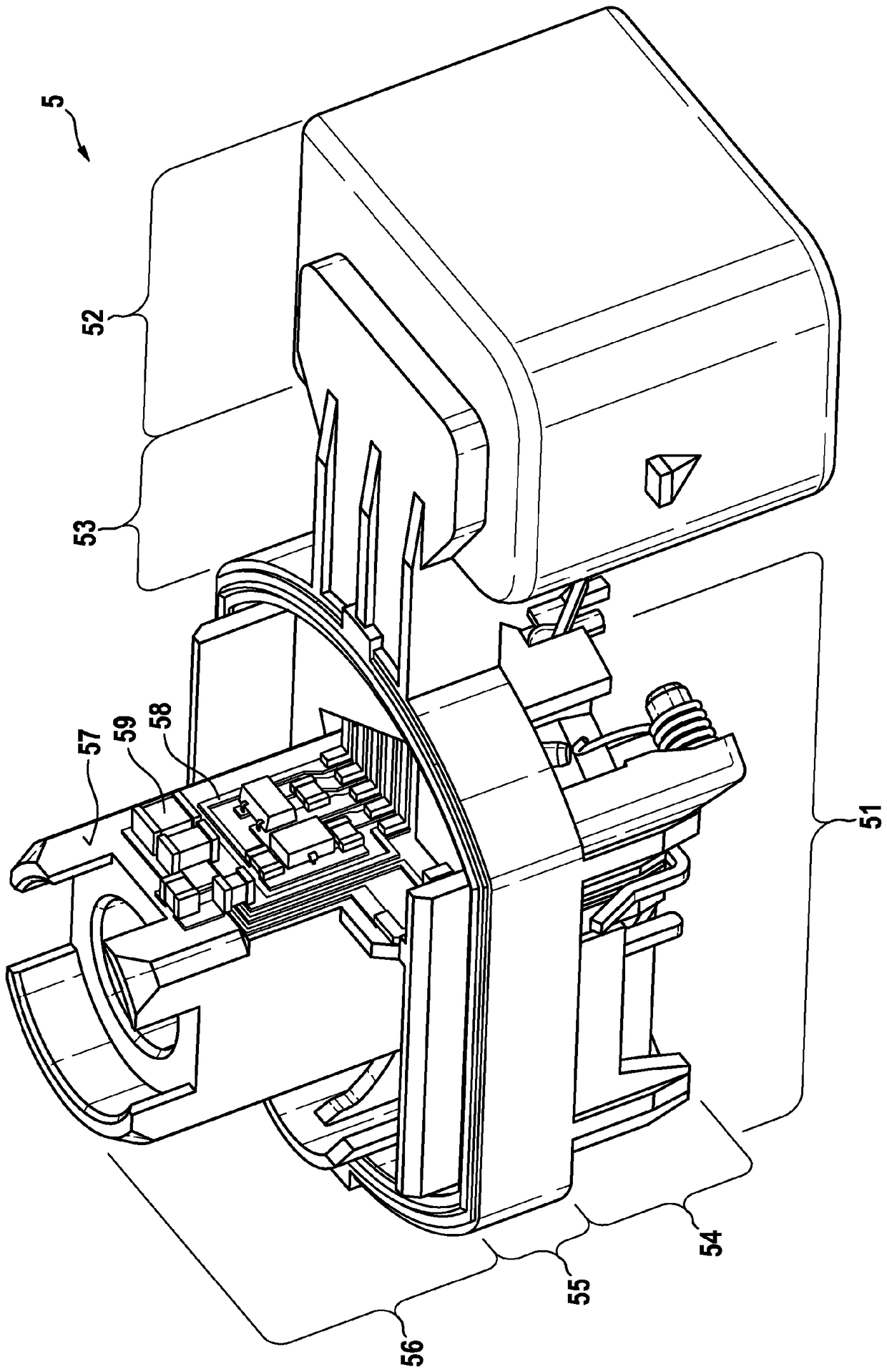

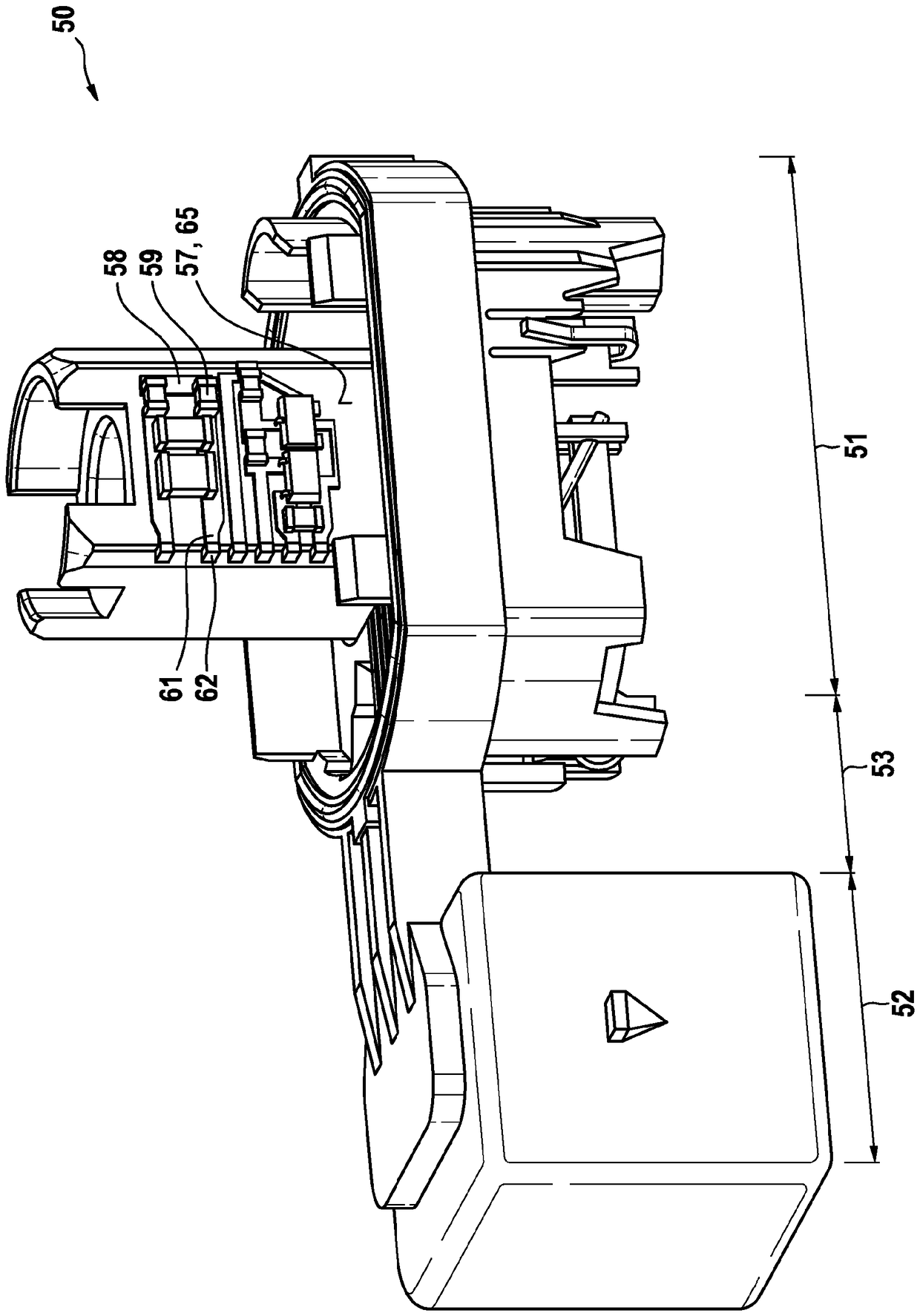

[0044] figure 1A perspective view of a drive module 1 in the form of a window regulator module for use in a motor vehicle with electric window regulators is shown. The drive module 1 has a drive motor 2 arranged on a transmission housing 3 . Protruding from the transmission housing 3 is an output shaft 4 which is used to drive a mechanical device, for example for raising or lowering window panes in an electric window regulator system of a motor vehicle. Arranged between the gear housing 3 and the drive motor 2 is a contact element 5 which mechanically connects the drive motor 2 and the gear housing 3 to one another.

[0045] The drive motor 2 is accommodated in a pole housing 21 which at a first end 22 provides a bearing housing 23 for supportingly receiving a motor shaft (not shown). The contact part 5 is arranged on an end 24 of the pole housing 21 opposite the first end 22 .

[0046] The drive motor 2 is designed such that a commutator arranged on the motor shaft protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com