Tobacco curing kiln and tobacco curing process

A technology of curing process and flue-curing room, which is applied in the field of tobacco-curing room and tobacco leaf curing process, which can solve the problems of long curing time, low oil content of tobacco leaves, high power consumption, etc., and achieve short curing time and less variegated smoke , the effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

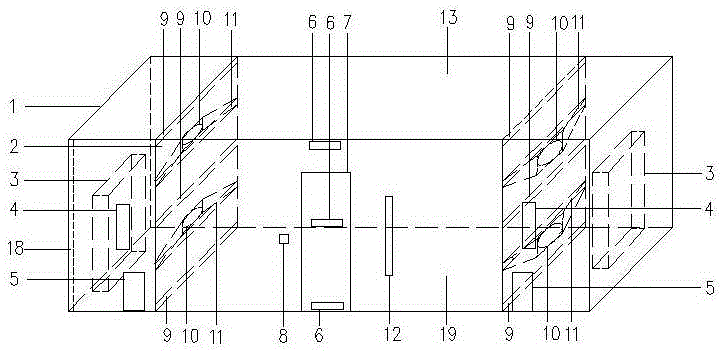

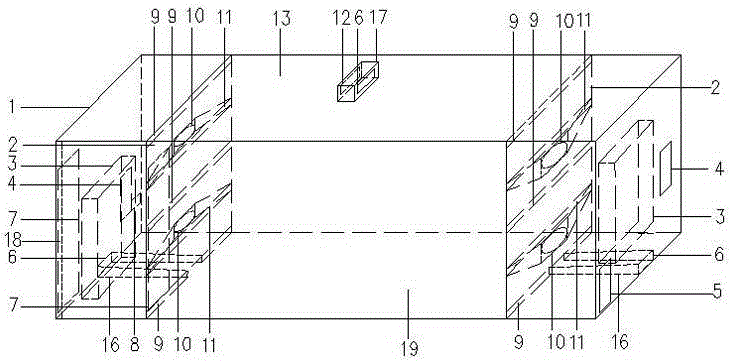

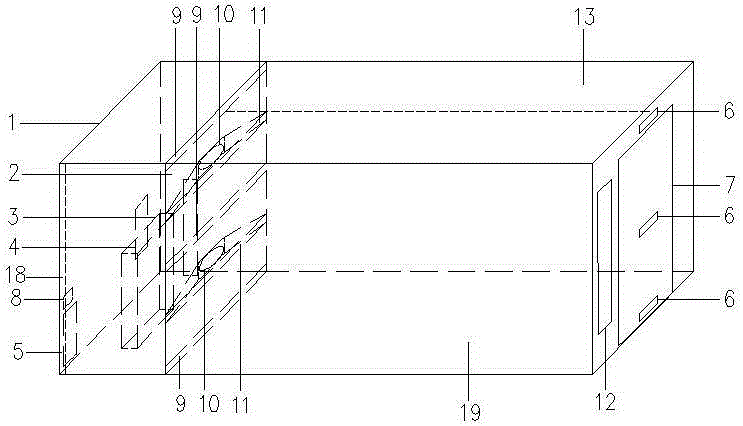

[0015] Such as figure 1 As shown in —4, a tobacco flue-curing room and tobacco leaf curing process are composed of an outer wall body, an inner wall body, a heater, an air inlet door, an inspection door, a moisture discharge port, a smoke door, a temperature and humidity control instrument, an air return port, and a circulation Fan, air outlet, observation window, roof, tobacco rack, tobacco leaves, moisture drainage channel, rain shelter, extruded board insulation layer and ground. The inner wall 2, the heater 3 is installed between the outer wall 1 and the inner wall 2, and the inspection door 5 is arranged on the front outer wall between the outer wall 1 and the inner wall 2, or arranged on the left or right On the side outer wall 1, the air inlet door 4 is arranged above or beside the inspection door, and the moisture outlet 6 is arranged on the outer wall and the smoke door above the smoke door 7, or on the side of the moisture discharge channel 16 under the heater. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com