A method for stabilizing and slow-curing Xiangyan No. 5 tobacco leaves

A curing method and tobacco leaf technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve problems such as difficult tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

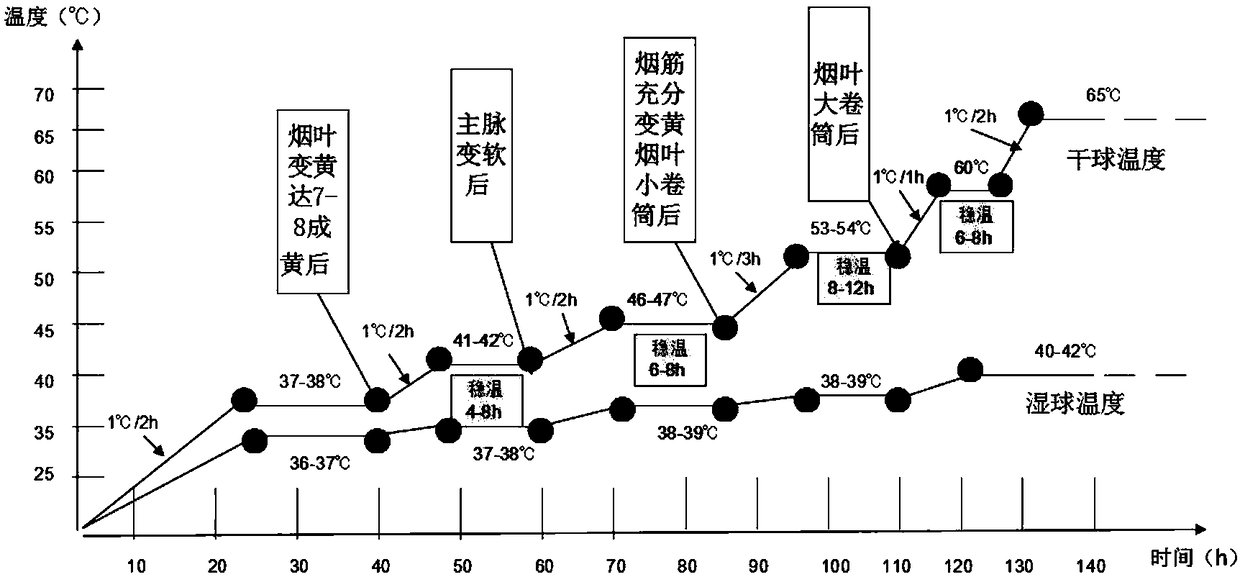

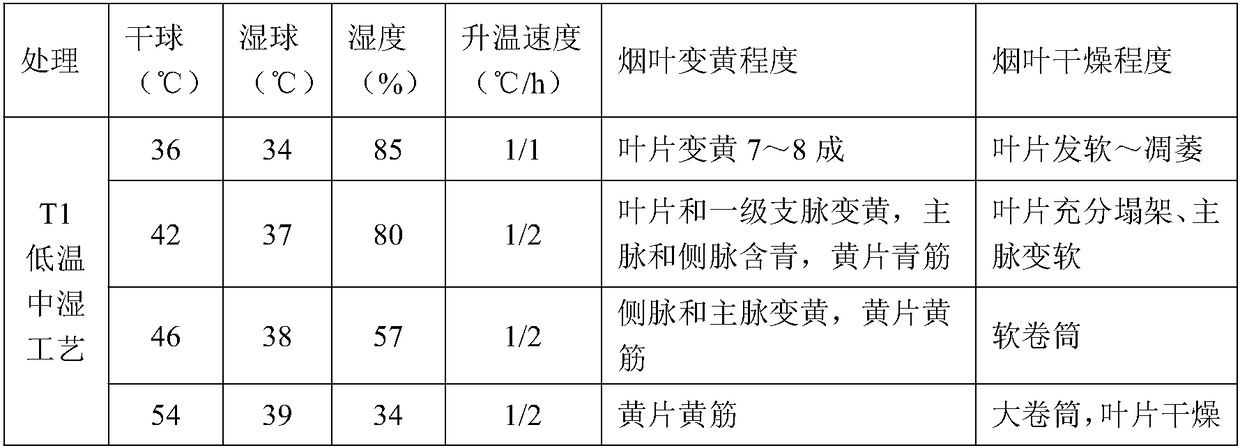

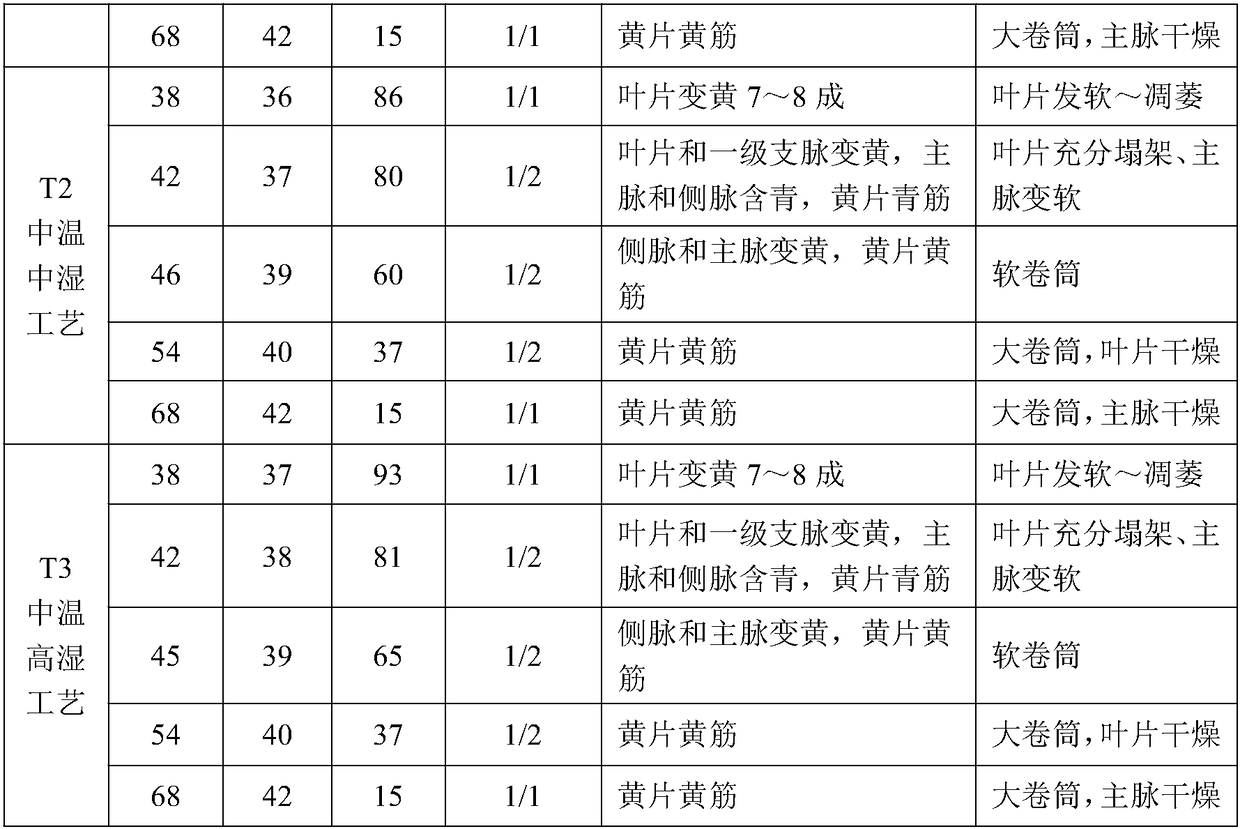

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 (marked as T4)

[0024] Step (1) Tobacco Leaf Selection and Compilation

[0025] (1-1) Determination of the tobacco leaves to be tested

[0026] The nutritional conditions, location and maturity of the tobacco leaves to be tested should be balanced and consistent.

[0027] (1-2) Labeled tobacco leaves

[0028] In order to ensure the accuracy of the test, representative tobacco leaves were determined before the tobacco leaves were installed in the barn, and 18 rods (clips) were processed for each, and their fresh weights were weighed and listed on the record. At the positions of 2, 4, and 6 meters in the room, there are 1 rod (clip) in the middle of the bottom, middle, and upper layers; after the tobacco leaves have regained moisture after curing, they are graded and analyzed for economic properties.

[0029] (1-3) Smoke filling method

[0030] Tobacco weaving and baking of tobacco rods, 120-150 pieces per rod, distance between rods 10-14cm, the number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com