High-wear-resistant super-toughness environment-friendly flame-retardant nylon gear

A flame retardant nylon, high wear resistance technology, applied in the field of gears, can solve the problems of poor wear resistance and low mechanical strength, and achieve the effects of good flame retardant performance, reducing black smoke and better flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

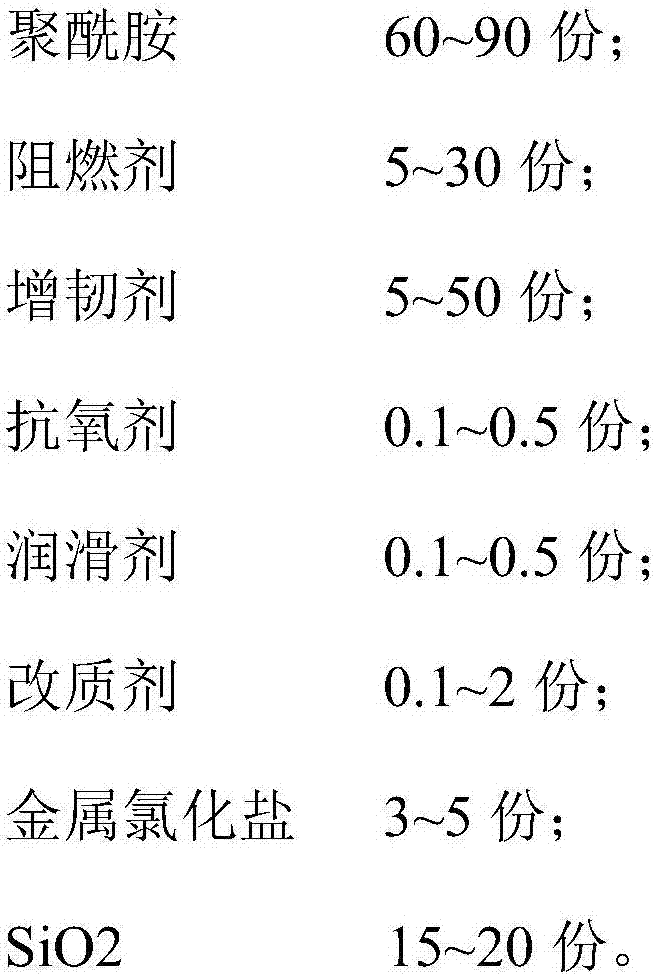

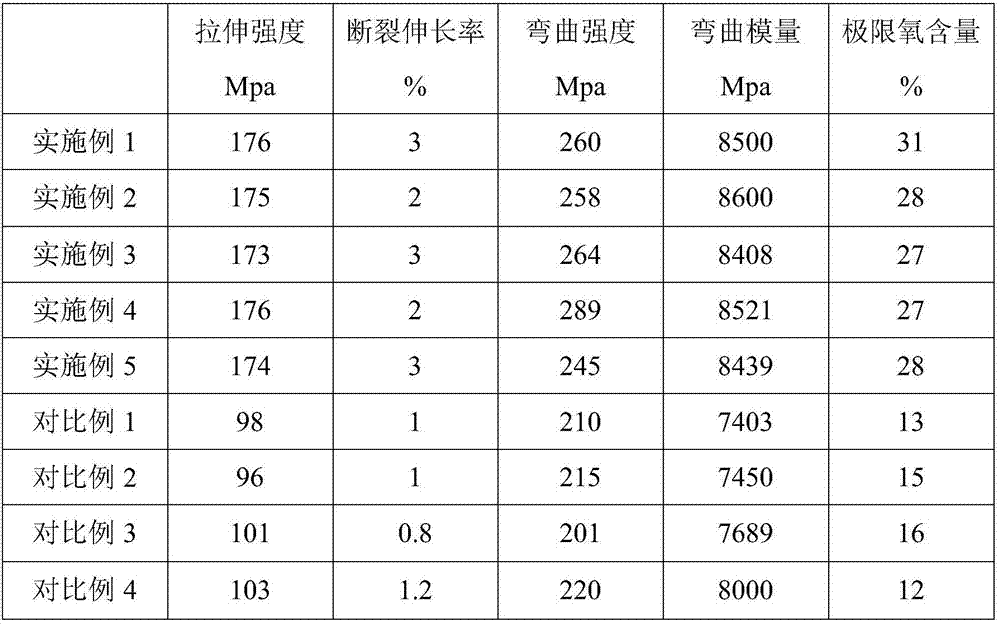

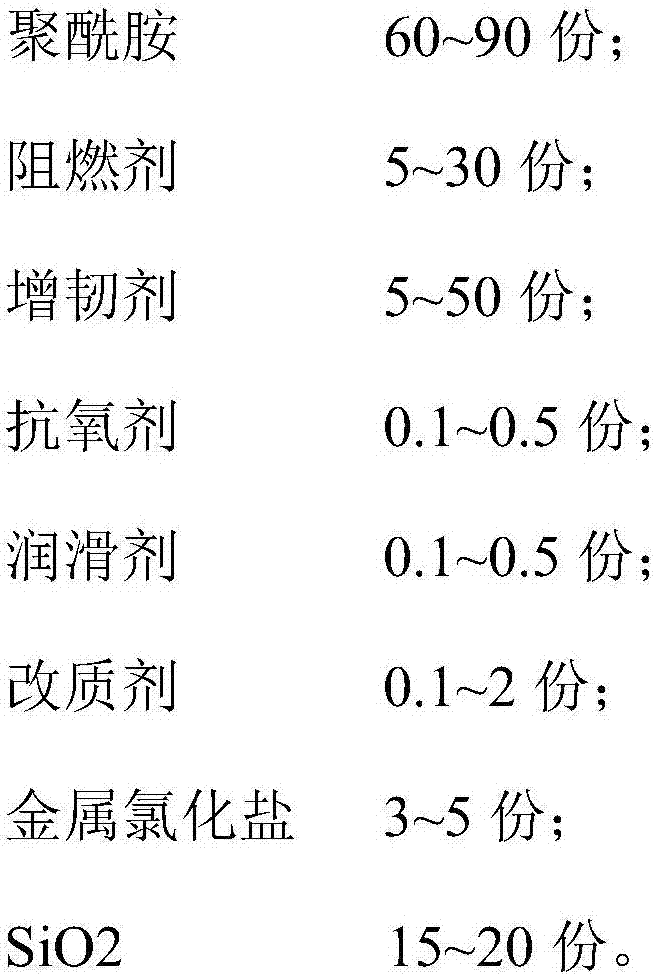

[0027] A gear, comprising 60-90 parts of polyamide grafted with polyolefin elastomer, 5-30 parts of flame retardant, the flame retardant is: 15%-25% of triphenyl phosphate, 15%-25% of decabromodiphenylethylene 35% to 45% of alkane, 10 to 15% of antimony trioxide, and the balance of montmorillonite; 5 to 50 parts of toughening agent; 0.1 to 0.5 parts of antioxidant; 0.1 to 0.5 parts of lubricant; 0.1 to 2 parts of modifier; 3 to 5 parts of a mixture of lithium chloride and gallium chloride, wherein the molar ratio of lithium chloride to gallium chloride is 1:1.2 to 1.5; 15 to 20 parts with a length of 200 to 300 μm, Fibrous SiO with an aspect ratio of 50-80 2 . Example 2

Embodiment 2

[0028] A gear, comprising 60-90 parts of polyamide grafted with polyolefin elastomer, 5-30 parts of flame retardant, the flame retardant is: 15%-25% of triphenyl phosphate, 15%-25% of decabromodiphenylethylene 35% to 45% of alkane, 10 to 15% of antimony trioxide, and the balance of montmorillonite; 5 to 50 parts of toughening agent; 0.1 to 0.5 parts of antioxidant; 0.1 to 0.5 parts of lubricant; 0.1 to 2 parts of modifier; 3 to 5 parts of a mixture of lithium chloride and gallium chloride, wherein the molar ratio of lithium chloride to gallium chloride is 1:1.2 to 1.5; 15 to 20 parts with a length of 200 to 300 μm, Fibrous SiO with an aspect ratio of 50-80 2 . Example 3

Embodiment 3

[0029] A gear, comprising 60-90 parts of polyamide grafted with polyolefin elastomer, 5-30 parts of flame retardant, the flame retardant is: 15%-25% of triphenyl phosphate, 15%-25% of decabromodiphenylethylene 35% to 45% of alkane, 10 to 15% of antimony trioxide, and the balance of montmorillonite; 5 to 50 parts of toughening agent; 0.1 to 0.5 parts of antioxidant; 0.1 to 0.5 parts of lubricant; 0.1 to 2 parts of modifier; 3 to 5 parts of a mixture of lithium chloride and gallium chloride, wherein the molar ratio of lithium chloride to gallium chloride is 1:1.2 to 1.5; 15 to 20 parts with a length of 200 to 300 μm, Fibrous SiO with an aspect ratio of 50-80 2 . Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com