Environment-friendly dust-free smokeless metal additive production process

A metal additive and production process technology, applied in the field of environmentally friendly dust-free and smoke-free metal additive production process, can solve the problems of polluting the casting production environment, polluting the production operation environment, etc., and achieve the effects of reducing consumption, reducing black smoke, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with the examples, the specific implementation of the present invention will be further described in detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0021] An environment-friendly, dust-free and smoke-free metal additive production process of the present invention comprises the following steps:

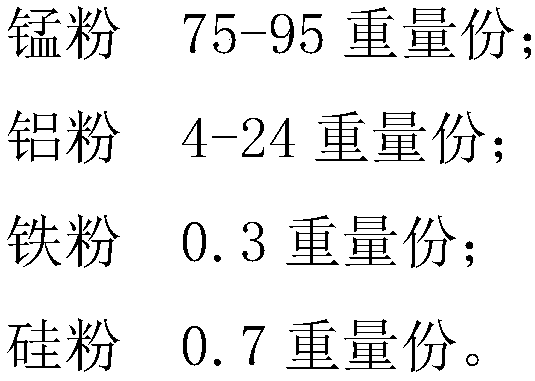

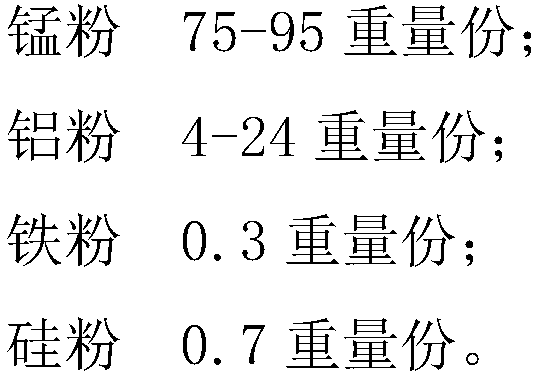

[0022] (1) Raw material screening: choose manganese powder, aluminum powder, iron powder and silicon powder with a particle size of 10-60 mesh after crushing;

[0023] (2) Mixing of raw materials: Add manganese powder, aluminum powder, iron powder and silicon powder into the stirring device according to the proportion, and stir for 20-30 minutes to fully mix the raw material powder;

[0024] (3) Release agent spraying: the release agent is loaded into the compression device, and before the metal additive is pressed each time, the compression device sprays a cer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com