Temperature control type stamping die for high-strength steel plate and method

A high-strength steel plate and stamping die technology, applied in forming tools, manufacturing tools, metal processing, etc., can solve the problems of inability to realize real-time monitoring of stamping die head temperature, uneven cooling effect, etc., to ensure quality stability and production efficiency. , The structure is simple, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

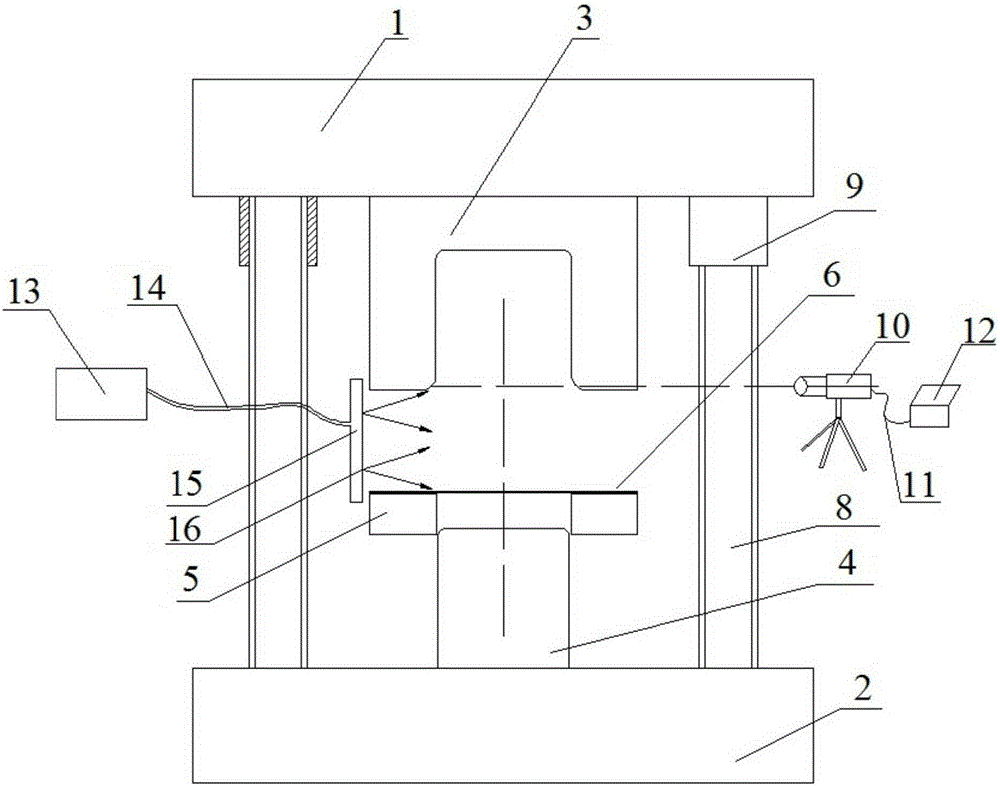

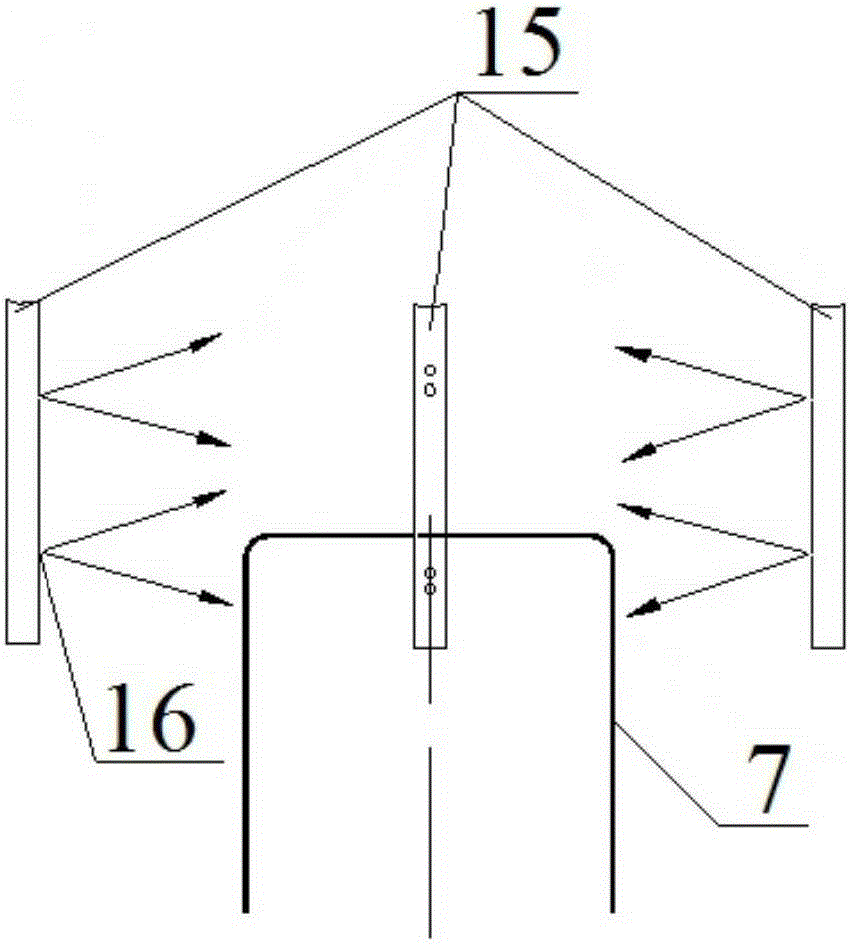

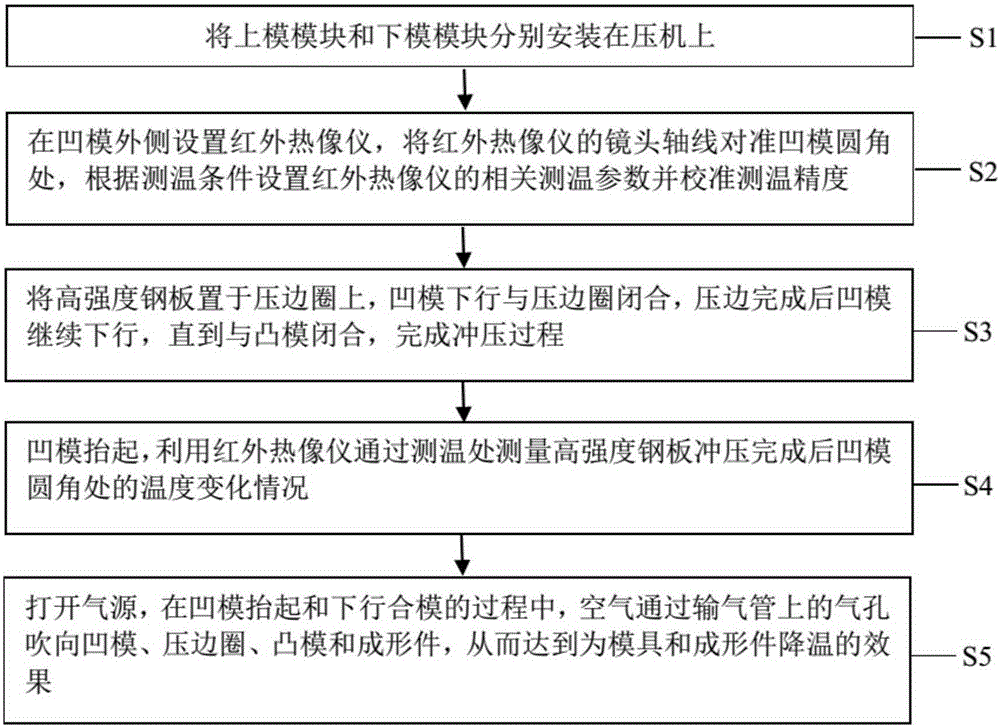

[0036] like figure 1 As shown, this embodiment includes: guide post 8, high-strength steel plate 6, cooling system, temperature measurement system, upper die module and lower die module arranged in parallel, wherein: the upper die module and the lower die module are connected by guide post 8, The high-strength steel plate 6 is stamped by closing the mold, the temperature measurement system measures the temperature of the upper mold module, and the cooling system cools the upper mold module, the lower mold module and the formed part 7 of the high-strength steel plate 6 respectively.

[0037] A guide sleeve 9 is slidably arranged on the guide post 8 .

[0038] The upper mold module includes: an upper mold base 1 and a die 3 arranged below the upper mold base 1 .

[0039] The lower mold module includes: a blank holder 5 , a punch 4 and a lower mold base 2 connected sequentially from top to bottom.

[0040] The outer side of the end of the concave mold 3 is a right angle, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com