Full-automatic loading system and method for organic garbage flash-vaporization spray-explosion treatment process

A treatment process and technology for organic waste, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as secondary pollution, high cost of silo infrastructure, leakage of leached liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

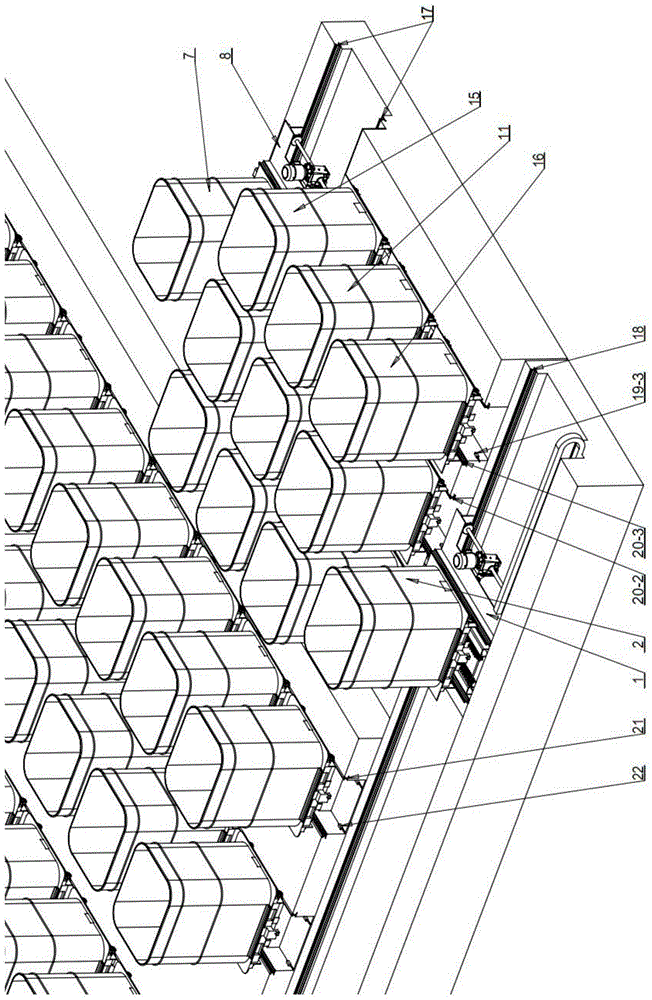

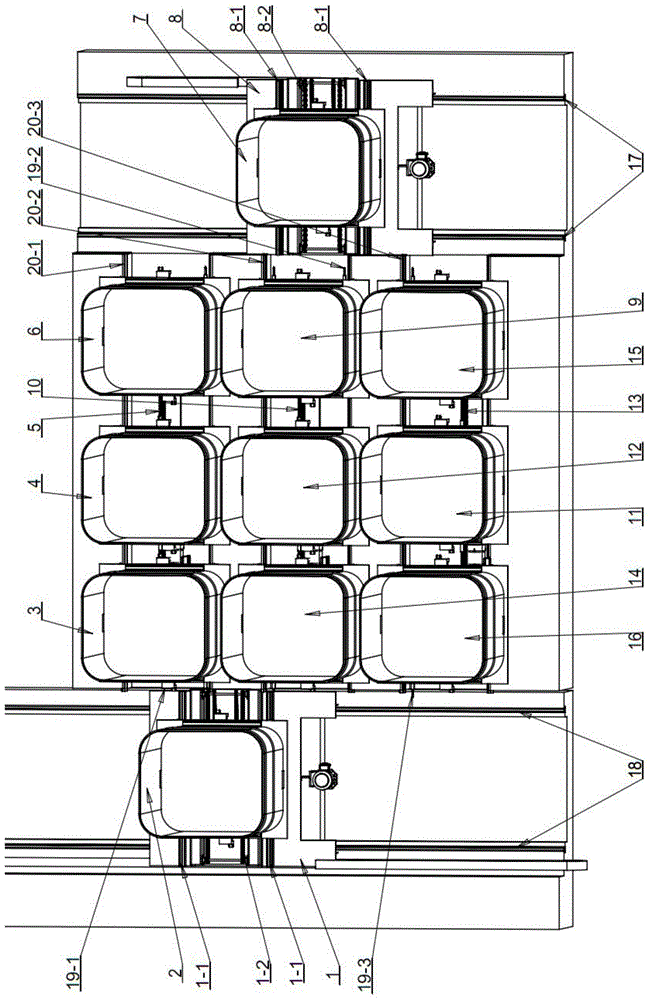

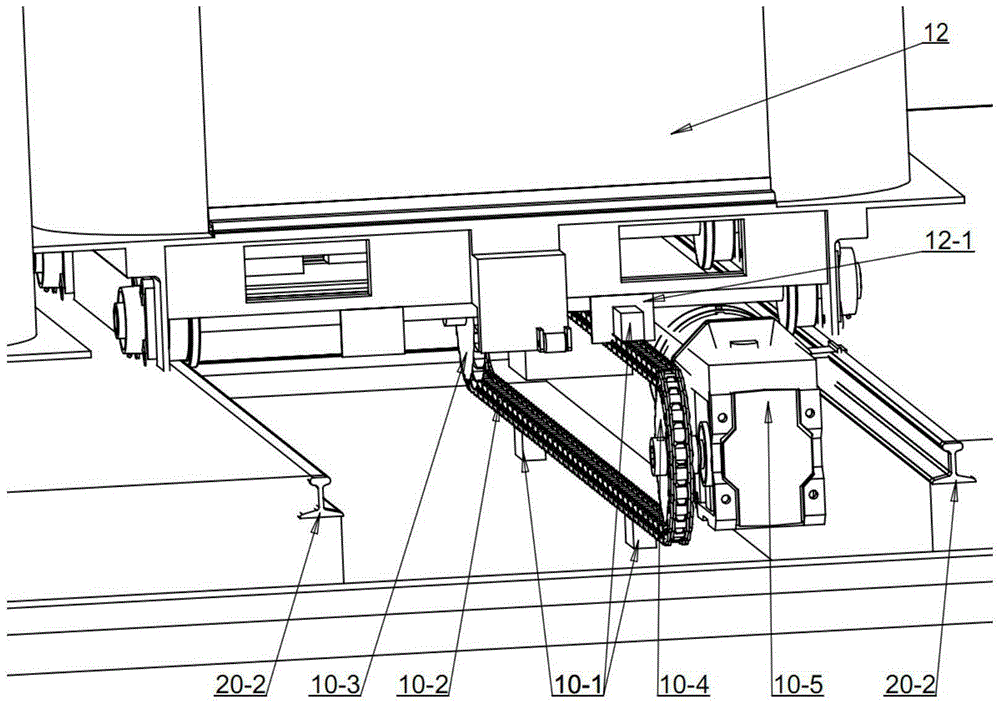

[0027] like Figure 1-4 as shown,

[0028] A fully automatic charging system for organic waste flash spray explosion treatment process, including a loading conveyor, a material barrel and a carrying trolley. 3 pairs—longitudinal car changing track A 20-1, longitudinal car changing track B 20-2, longitudinal car changing track C 20-3, and a longitudinal car changing drive mechanism is arranged between the two longitudinal car changing tracks of each pair. Therefore, there are also 3 sets of longitudinal car-changing drive mechanisms—longitudinal car-changing driving mechanism A5, longitudinal car-changing driving mechanism B10, and longitudinal car-changing driving mechanism C13. One end of all longitudinal car-changing tracks is provided with the longitudinal car-changing track Vertical horizontal transfer track 18, the horizontal transfer track is provided with a horizontal transfer car armor 1, and the other end of all longitudinal transfer tracks is provided with a horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com