Full-automatic material storage and conveying system and method for organic garbage flash-evaporation and spray-explosion treatment process

A technology for processing and organic waste, applied in mechanical conveyors, transportation and packaging, conveyors, etc., can solve the problems of secondary pollution, high cost of silo infrastructure, leakage of leachate, etc., to reduce the cost of fixed assets. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given hereby, and the details are as follows:

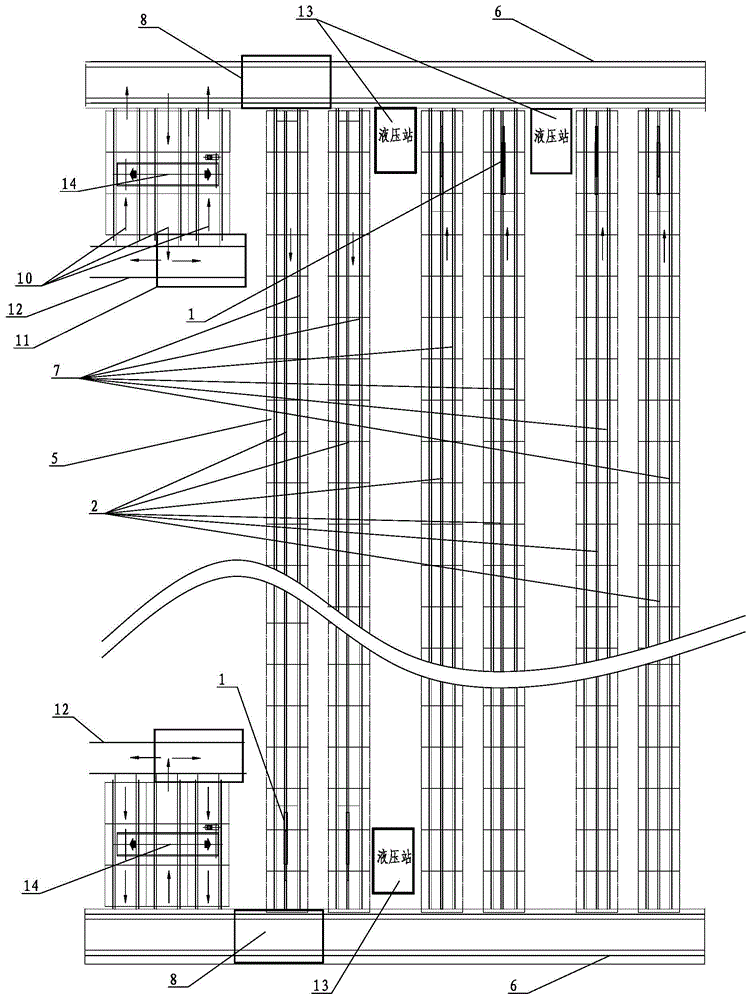

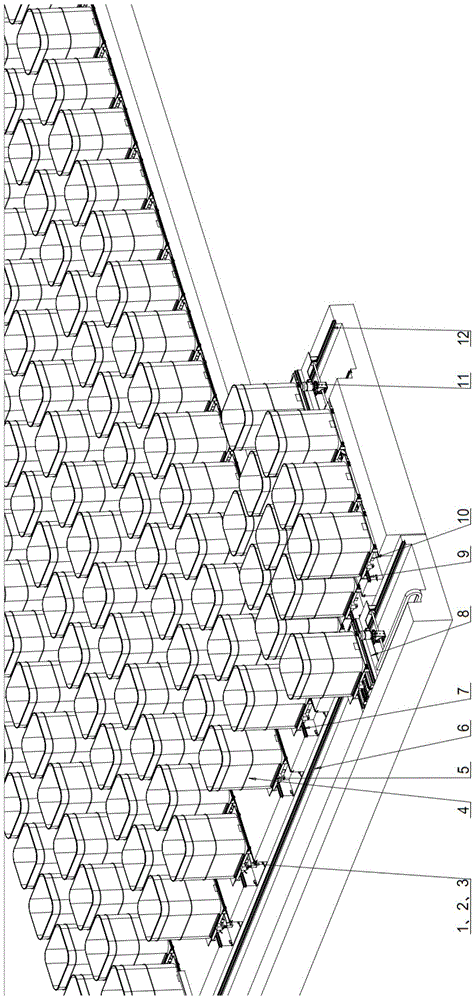

[0020] Such as figure 1 and 2 as shown,

[0021] A fully automatic material storage and transportation system for organic waste flash spray explosion treatment process, comprising a hydraulic station 13, a material storage system longitudinal rail 7, and a longitudinal traction guide rail 3 is arranged between each pair of two material storage system longitudinal rails, A longitudinal traction slideway 2 is arranged on the longitudinal traction guide rail in an axially moving manner, and the traction hydraulic cylinder 1 drives the longitudinal traction slideway 2 to reciprocate on the longitudinal traction guide rail 3. There are horizontal transport rails 6 perpendicular to the longitudinal rails of the storage system, and each pair of transverse transport rails 6 is provided with a hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com