Automatic brick stacking machine

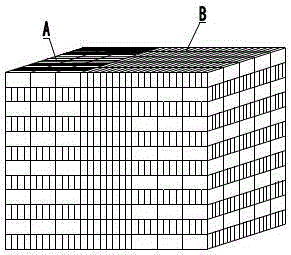

A brick stacking machine, automatic technology, applied in the stacking of objects, unstacking of objects, transportation and packaging, etc., can solve the problems of high labor intensity for operators, low work efficiency, high construction costs, etc., and achieve good general performance , Guarantee the locking performance and improve the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0040] It should be noted that the orientation words such as "front", "rear", "left" and "right" mentioned in the embodiments of the present invention are consistent with the directions of front, rear, left and right marked in the drawings.

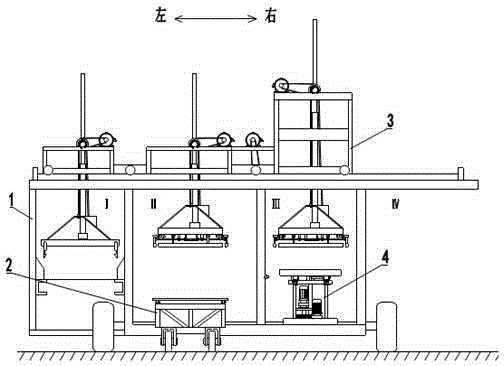

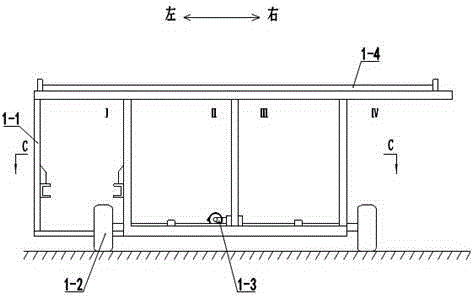

[0041] see figure 2 , image 3 The automatic brick stacking machine of the present invention includes a movable base 1, a feeding device 2, a layer brick lifting and stacking device 3 and a layer brick placement posture adjustment device 4; the movable base 1 includes a main body frame 1 -1 and horizontal lifting rails 1-4, the internal space layout of the main frame 1-1 is divided into pallet collection area I, material loading work area II, layer brick posture adjustment work area III and layer brick stacking Working area IV, the horizontal lifting track 1-4 is arranged on the top of the main frame 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com