Rhenium-free low-density high-performance nickel-based monocrystalline high-temperature alloy and heat treatment technology thereof

A technology of nickel-based single crystal and high-temperature alloy, which is applied in post-processing, single crystal growth, single crystal growth, etc., can solve the problems of cost and density increase, resource depletion, easy precipitation of TCP, etc., and achieve the effect of reducing the cost of the alloy

Active Publication Date: 2015-12-30

INST OF METAL RESEARCH - CHINESE ACAD OF SCI

View PDF7 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, while the temperature bearing capacity of the alloy is improved, its cost and density are also significantly increased, and the structure stability of the Re-containing alloy is poor, and harmful TCP phases are easily precipitated.

Re resources in our country are very limited. Once a large amount of Re-containing alloys are used, the price of Re will soon rise, the supply will be tight, and the resources will be exhausted.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

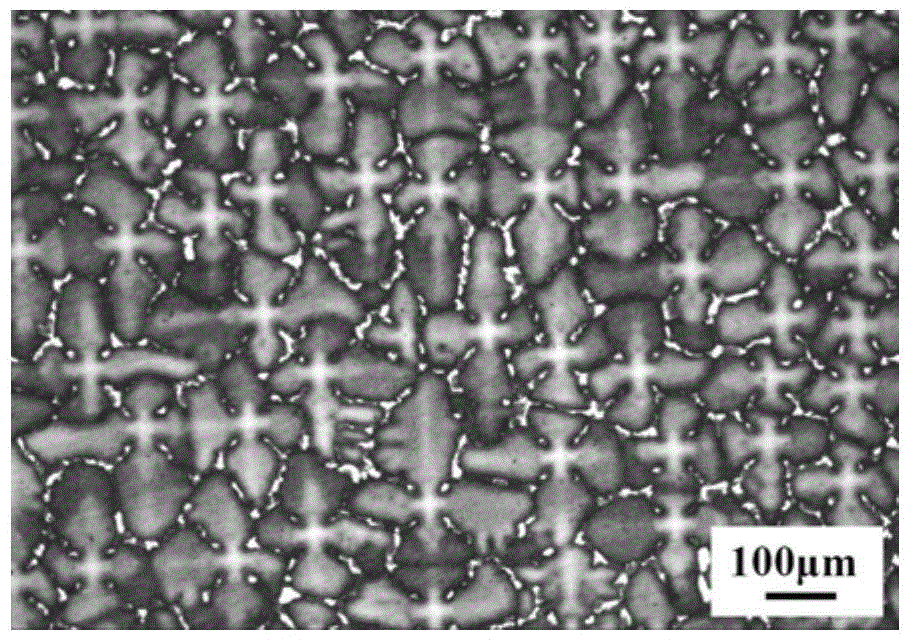

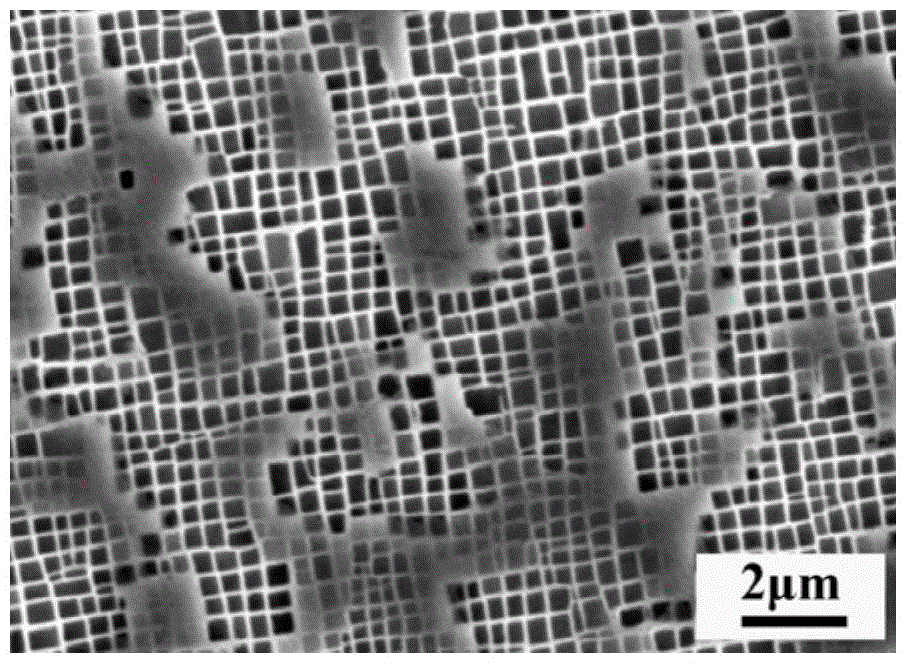

The invention discloses a rhenium-free low-density high-performance nickel-based monocrystalline high-temperature alloy and a heat treatment technology thereof, and belongs to the field of nickel-based monocrystalline high-temperature alloys. The alloy comprises 6.0-8.0wt% of Cr, 8.0-10.0wt% of Co, 6.0-9.0wt% of W, 1.0-3.0wt% of Mo, 0-2wt% of Nb, 3.0-6.0wt% of Al, 1.0-3.0wt% of Ti, 1.0-5.0wt% of Ta, 0.02-0.06wt% of C, 0.001-0.003wt% of B, 0-0.02wt% of Ce, 0-0.01wt% of Y and the balance Ni. The alloy has excellent low-temperature, middle-temperature and high-temperature strength and antioxidation performances, has lasting and low-cycle fatigue behavior the same to that of a second monocrystalline high temperature alloy CMSX-4 with Re content of 3wt%, does not contain a noble element Re, reduces an alloy cost by 70% or more and reduces alloy density by about 3%.

Description

technical field [0001] The invention relates to the field of nickel-based single crystal superalloy, in particular to a rhenium-free low-density high-performance nickel-based single crystal superalloy and a heat treatment process thereof. Components, such as turbine blades of aero-engines, guide vanes, etc. Background technique [0002] The development of high thrust-to-weight ratio engines has continuously put forward higher requirements on the temperature-bearing capacity of hot-end components. The service temperature of the first-generation single-crystal superalloy is 25-30℃ higher than that of the oriented columnar superalloy; the second-generation single-crystal superalloy (CMSX-4, ReneN5, etc.) is due to the addition of about 3wt. ), which is 30°C higher than that of the first-generation single-crystal superalloy; the Re content in the third-generation single-crystal superalloy is about 6wt.%, which can further increase the temperature resistance by 30°C to about 115...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C30B29/52C30B33/02C22C19/05C22F1/10

CPCC30B29/52

Inventor 张少华王莉张功谢光张健楼琅洪

Owner INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com