A colored filament yarn spinning device for imitation cotton fabric and its filament yarn processing method

A processing method and filament yarn technology, which is applied to spinning machines, textiles, papermaking, and drafting equipment, can solve the problems of low proportion and low output of color-spun yarns, and shorten the production process and cycle. Effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

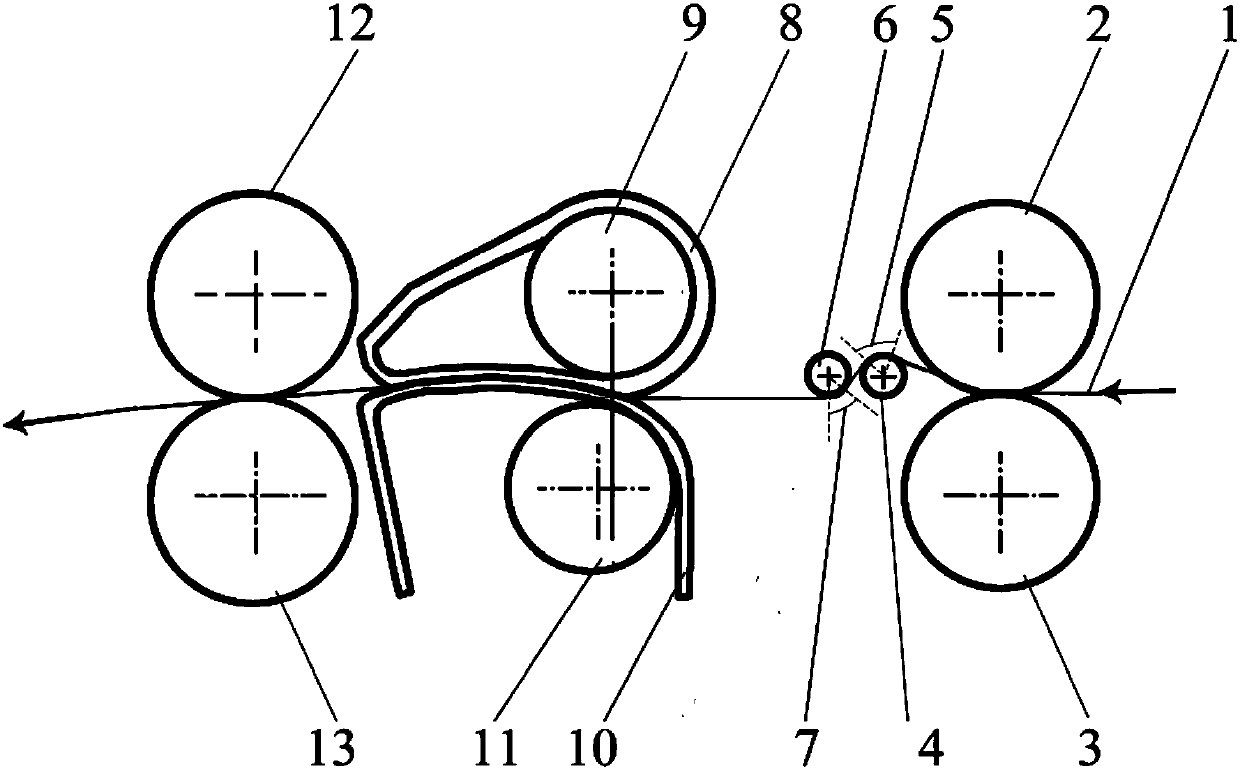

[0037] The ratio of red and white filaments composing the multifilament is 3:7. The target yarn is light red.

[0038] In the rear drafting zone: the diameter of the two rollers is 25mm, and the horizontal center distance is 50mm. The pressure of the rear roller is 16 daN / double spindle, and the pressure of the middle roller is 14 daN / double spindle. The diameter of the applied pressure roller is 6 mm, and the vertical distance between the center of the bottom roller 11 in the lower pressure roller 4 is 30 mm. The number of emery skins from small to large is as follows: the number of emery skins of the lower press roller is 35 mesh, the number of emery skins of the upper press roller is 45, and the two aprons of the middle roller are both 50 mesh. Respectively: 500, 350, 297 grains; the wrapping angle 5 formed by the lower pressing roller and the yarn is 80°; the wrapping angle 7 formed by the upper pressing roller and the yarn is 45°.

[0039] The front drafting zone is compose...

Embodiment 2

[0043] The ratio of red and blue filaments composing the multifilament is 5:5. The target yarn is purple.

[0044] In the rear drafting zone: the diameter of the two rollers is 25mm, and the horizontal center distance is 50mm. The pressure of the rear roller is 14 daN / double spindle, and the pressure of the middle roller is 12 daN / double spindle. The diameter of the applied pressure roller is 6 mm, and the vertical distance between the center of the bottom roller 11 in the lower pressure roller 4 is 30 mm. The number of emery skins from small to large is: the number of emery skins of the lower press roller is 45, the number of emery skins of the upper press roller is 50, and the two aprons of the middle roller are both 60 meshes, corresponding The particle sizes are respectively: 350, 297, and 250 grains; the wrapping angle 5 formed by the lower pressing roller and the yarn is 60°; the wrapping angle 7 formed by the upper pressing roller and the yarn is 35°.

[0045] The front d...

Embodiment 3

[0049] The ratio of red, white and blue filaments composing the multifilament is 3:2:5. The target yarn is light purple.

[0050] In the rear drafting zone: the diameter of the two rollers is 25mm, and the horizontal center distance is 50mm. The pressure of the rear roller is 12 daN / double spindle, and the pressure of the middle roller is 10 daN / double spindle. The diameter of the applied pressure roller is 6 mm, and the vertical distance between the center of the bottom roller 11 in the lower pressure roller 4 is 30 mm. The number of emery skins from small to large is as follows: the number of emery skins on the lower press roller is 50, the number of emery skins on the upper press roller is 60, and the two aprons of the middle roller are both 80 meshes, corresponding to the particle size They are: 297, 250, and 178 grains; the wrapping angle 5 formed by the lower pressing roller and the yarn is 45°; the wrapping angle 7 formed by the upper pressing roller and the yarn is 25°....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com