Plate, heating plate with same, and preparation process of heating plate

A heating plate and panel technology, applied in the field of panels and decorative panels, can solve problems such as difficult maintenance, increased construction load, and long construction period, and achieve the effects of easy installation and disassembly, reduced laying costs, and convenient and reliable replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

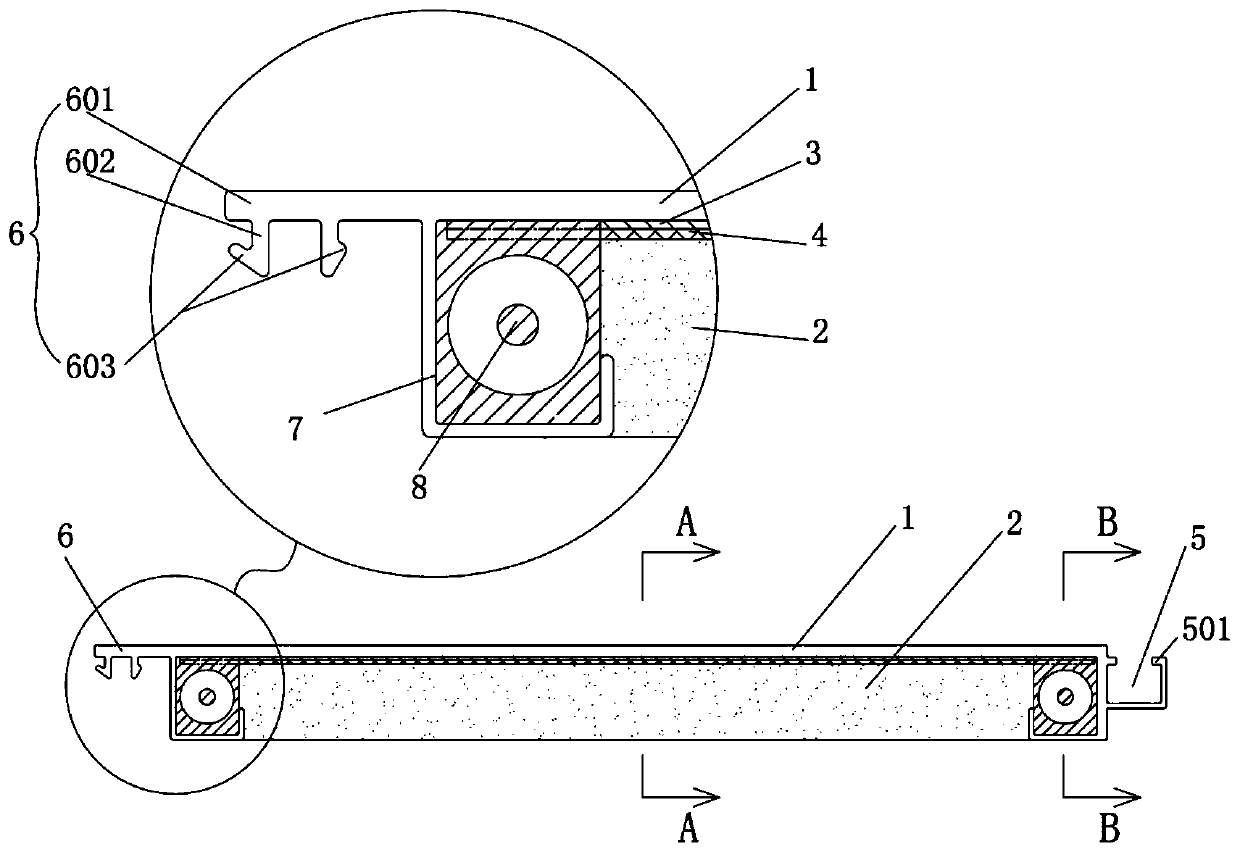

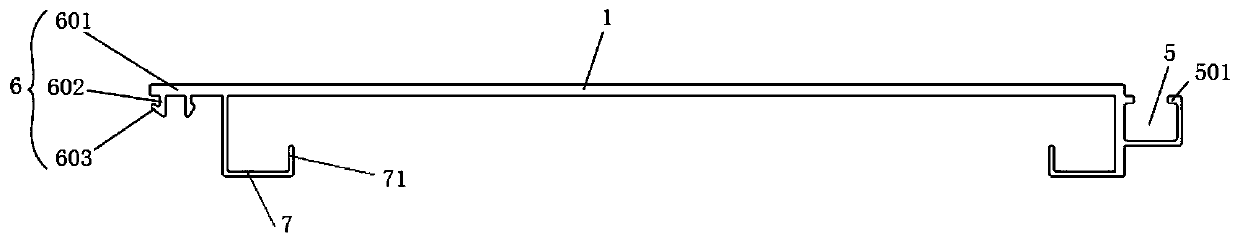

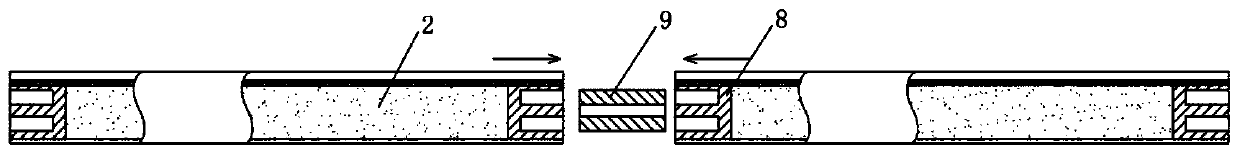

[0040] Such as Figure 1-Figure 3 , Figure 5 As shown, a heating plate described in this embodiment includes a heating layer 3, a docking socket 8, a filling layer 2 and a board 1, and the docking socket 8 is installed on the two mounting frames 7 of the board 1, and the filling layer 2 is filled and positioned at Between the two installation frames 7 of the board 1 , and the heating layer 3 is attached to the lower side of the board by pressing the filling layer 2 , and the heating layer 3 is electrically connected to the docking socket 8 .

[0041] In order to make installation and disassembly easy, when a large-area floor or wall panel is used as a floor or wall panel, after local damage (especially in the middle position), you only need to connect the slot and chuck of one of the heating boards with the other heating board during disassembly. The card slot and the clamp head can be separated rigidly, so that the local maintenance and replacement are convenient and reliab...

Embodiment 2

[0054] In the preparation process of a heating plate described in this embodiment, the heating plate to be prepared adopts the structure of the heating plate in Example 1, and specifically includes the following preparation steps:

[0055] S1. Material selection and plate making, select the metal plate to make the block 6, the slot 5, and the mounting frame 7 of the metal plate through extrusion and cutting processes;

[0056] S2. Cutting, cutting and blanking the formed plate according to the set size to obtain a metal plate;

[0057] S3. Surface treatment, rounding the corners of the metal plate, processing the surface decoration layer on the upper surface and processing and curing the wear-resistant layer on the surface decoration layer;

[0058] The steps of processing the surface decoration layer and processing and curing the wear-resistant layer on the surface decoration layer are as follows:

[0059] S31. After powder coating the surface of the metal plate, use wood gr...

Embodiment 3

[0074] The preparation process of a heating plate described in this embodiment, its general steps are consistent with embodiment 2, but different from embodiment 2 in that:

[0075] The steps of processing the surface decoration layer and processing and curing the wear-resistant layer on the surface decoration layer are as follows:

[0076] S311. Select the decorative layer base material that has been sprayed or electrophoresed;

[0077] S312. Wrap the transferred substrate with wood grain thermal transfer paper, put the front of the wood grain thermal transfer paper opposite to the front of the transferred substrate, and fix the interface of the paper with high temperature resistant adhesive tape to prevent The wood grain heat transfer paper is released;

[0078] S313. Pressurize and heat the flatbed thermal transfer machine, the transfer temperature is 160-180°C, and the time is 18-25 seconds;

[0079] S314. Tear off the heat transfer paper and use PET heat transfer film t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com