Cloth cutting machine applied to clothing production

A cloth cutting machine and cloth cutting technology, applied in the cutting of textile materials, textiles and paper making, etc., can solve the problems of reducing the versatility of the cloth cutting machine, entanglement of power cords, and non-adjustable, etc., to achieve fast transmission, improve adjustment accuracy, The effect of extending the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

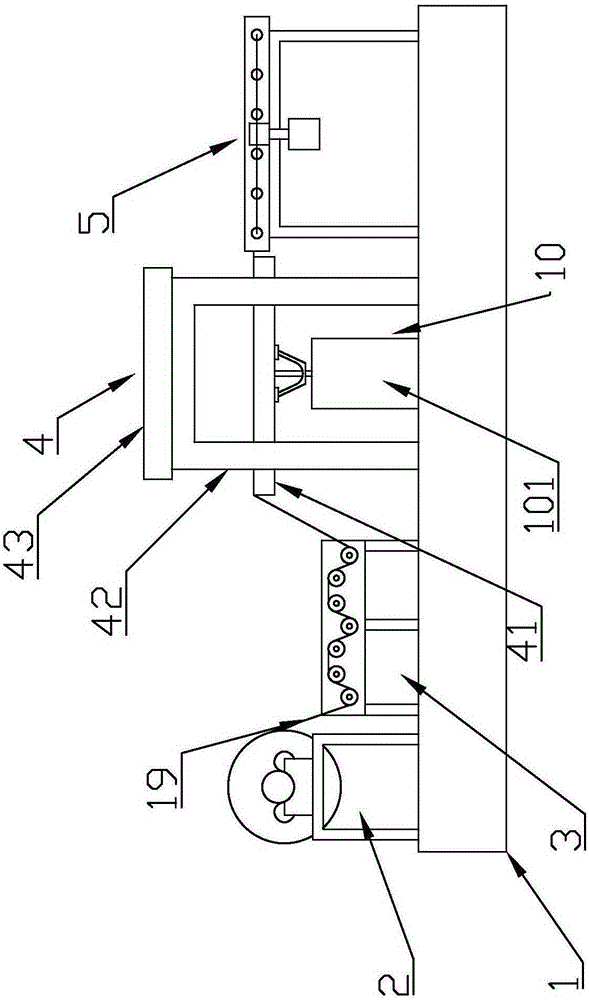

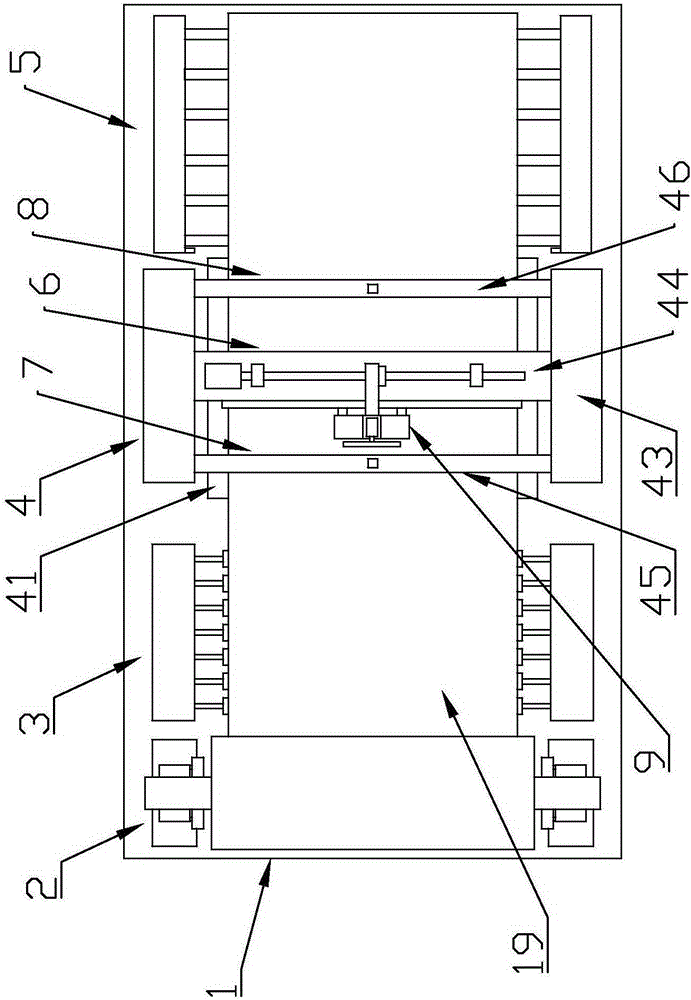

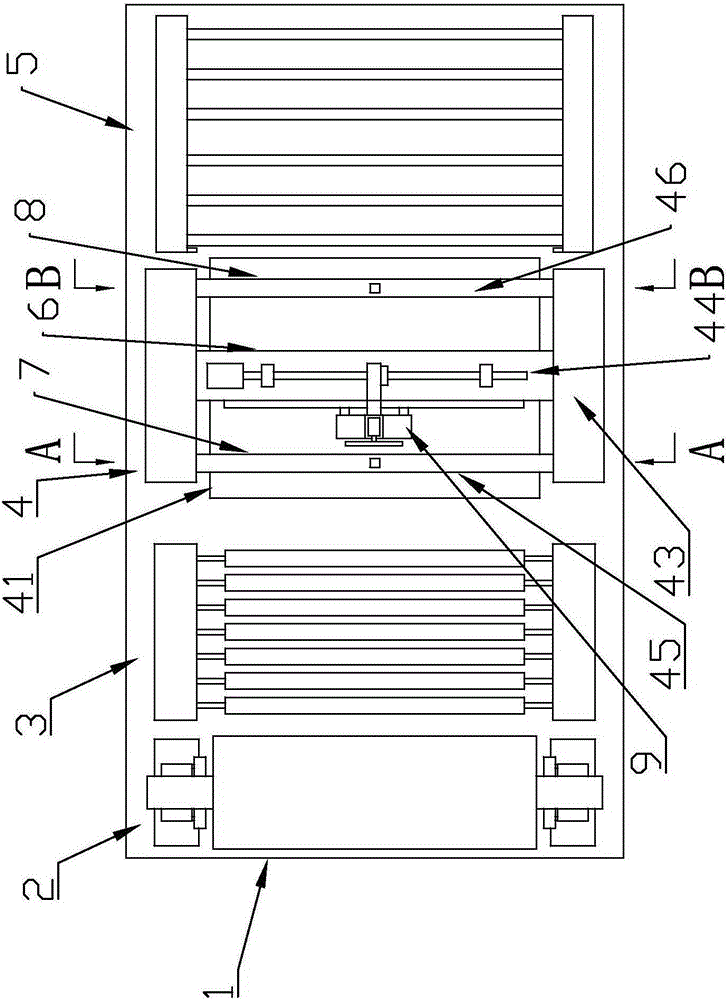

[0038] Such as Figure 1 to Figure 16 As shown, a cloth cutting machine applied to garment production includes a cloth cutting frame 1 on which a cloth placing device 2 , a cloth cutting device 4 and a cloth receiving device 5 are sequentially installed from left to right. A cloth guiding device 3 is arranged between the cloth placing device 2 and the cloth cutting device 4 , and the cloth guiding device 3 is installed on the cloth cutting frame 1 . The cloth cutting device 4 comprises a cloth cutting platform 41 and a cloth cutting frame, and the cloth cutting frame includes a cloth cutting horizontal frame 44, a cloth cutting vertical frame 42 and a cloth cutting connecting frame 43, and the cloth cutting connecting frame 43 is fixed on the cloth cutting vertical frame 42, and the cloth cutting The vertical frame 42 is fixed on the cloth cutting frame 1 , and a cloth cutting horizontal frame 44 is arranged between the cloth cutting connecting frames 43 . The lower end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com