Lubricating and cooling system for wind power gearbox and wind power generating set

A wind power gearbox, lubrication and cooling technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, mechanical equipment, etc., can solve the problems that cannot meet the temperature requirements of the gearbox working condition, the single speed control of the cooling fan, etc., to meet the requirements Gearbox lubrication and cooling requirements, high integration and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

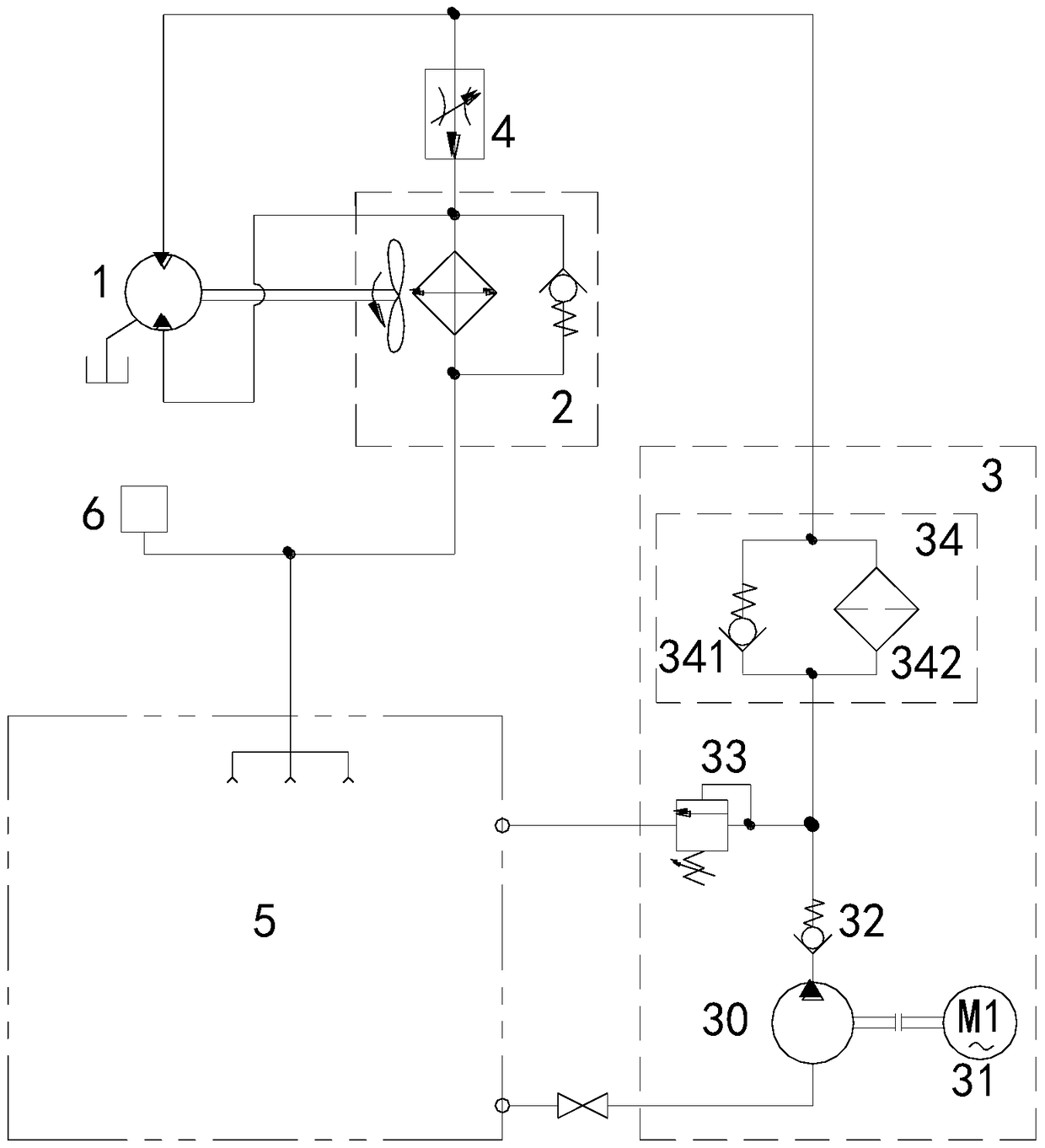

[0028] Such as figure 1 As shown, the wind power gearbox lubrication cooling system of this embodiment includes a hydraulic motor 1, a radiator 2 and a gear pump unit 3, the output shaft of the hydraulic motor 1 is connected to the cooling fan of the radiator 2, the hydraulic motor 1, the radiator 2 The oil inlet of the gear pump unit 3 communicates with the output end of the gear pump unit 3, the oil outlet of the radiator 2 communicates with the gear box 5, the input end of the gear pump unit 3 communicates with the gear box 5, and the oil outlet of the hydraulic motor 1 communicates with the radiator The oil inlet of device 2 is connected. In this embodiment, the lubricating medium in the gearbox 5 is used to directly drive the hydraulic motor 1, which can meet the lubrication and cooling requirements of the gearbox 5 of the high-power wind power generating set, without adding an oil source device, and has the advantages of low cost, small installation space, and high integ...

Embodiment 2

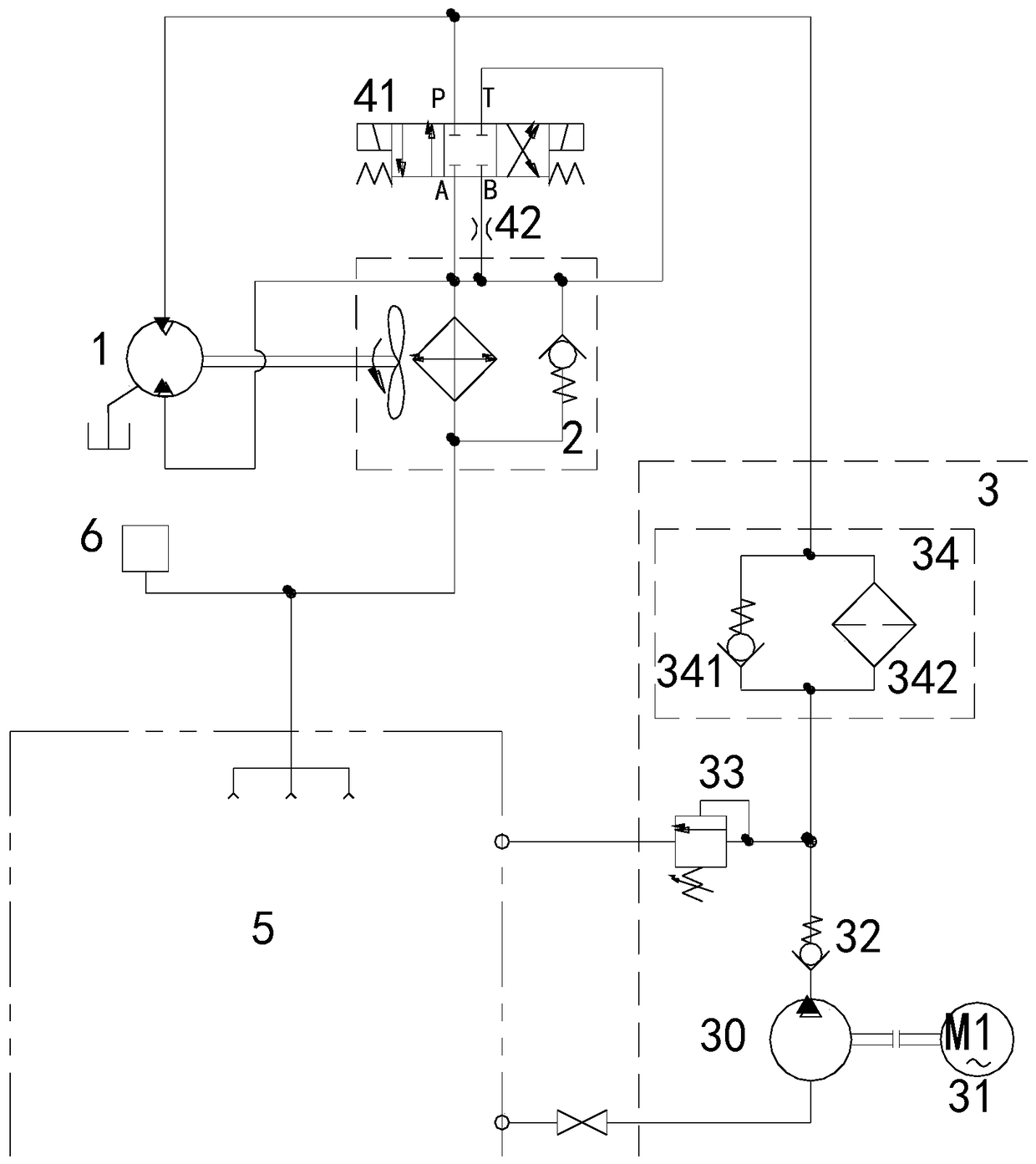

[0039] This embodiment is basically the same as the first embodiment, and the main difference is that the implementation of the control unit 4 is different. The control unit 4 includes a first reversing valve 41 and a throttle valve 42. In this embodiment, the first reversing valve 41 is a three-position four-way valve, and the throttle valve 42 is a damping hole.

[0040] Specific as figure 2As shown, the oil inlet P of the three-position four-way valve 41 is connected to the output end of the gear pump unit 3, and the oil suction port T and the first working oil port A of the three-position four-way valve 41 are respectively connected to the oil inlet port of the radiator 2 The second working oil port B of the three-position four-way valve 41 communicates with the oil inlet port of the radiator 2 through the damping hole 42 . It should be noted that, in addition to the three-position four-way valve, the first reversing valve 41 can also use a three-position six-way valve, ...

Embodiment 3

[0046] This embodiment is basically the same as Embodiment 1, and its main difference is:

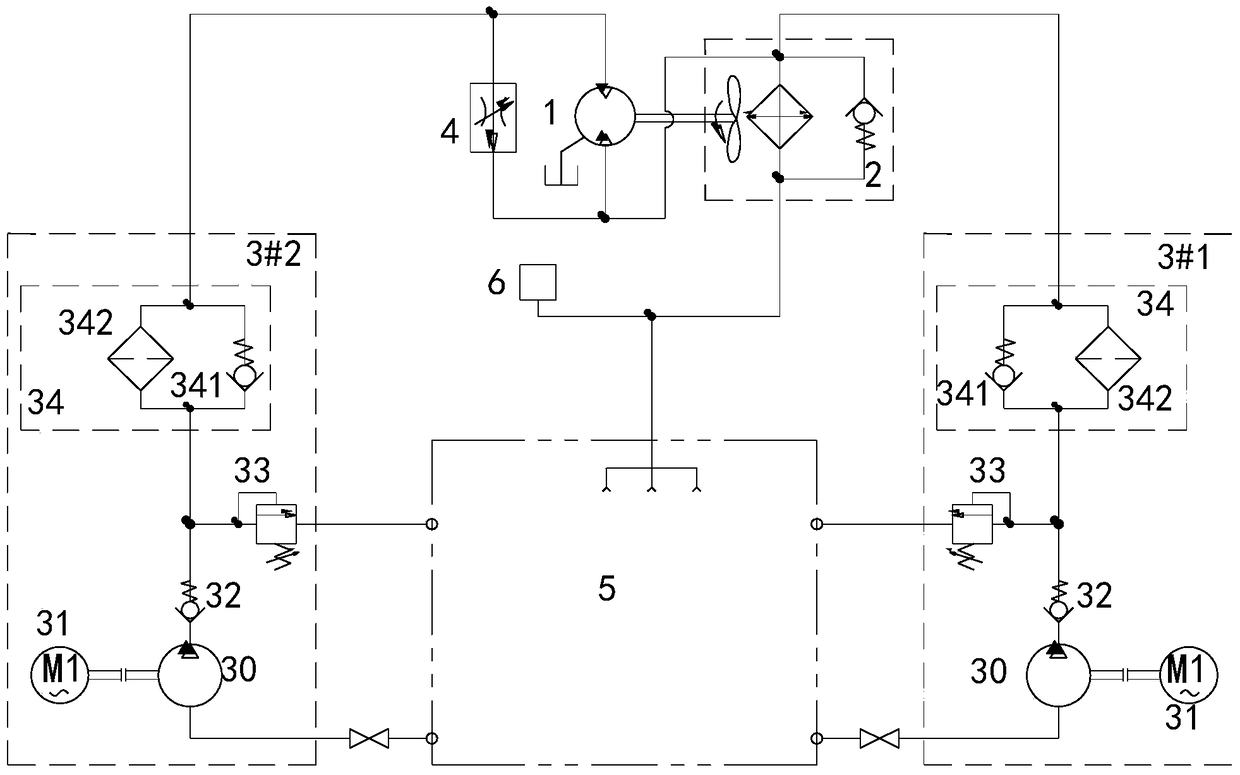

[0047] (1) The number of gear pump units 3 is different;

[0048] (2) The control unit 4 and the hydraulic motor 1 have different oil intake methods.

[0049] Such as image 3 As shown, in this embodiment, two gear pump units 3 are included, represented by gear pump unit 3#1 (right side) and gear pump unit 3#2 (left side) respectively; The output end of gear pump unit 3#1 on the side is connected, and the oil inlets of hydraulic motor 1 and control unit 4 are respectively connected with the output end of gear pump unit 3#2 on the left; and the output of control unit 4 and hydraulic motor 1 The end is connected with the oil inlet of the radiator 2.

[0050] The working principle of the wind power gearbox lubrication and cooling system in this embodiment is as follows:

[0051] For the gear pump unit 3#1 on the right, the motor 31 starts to work, drives the gear pump 30 to pump gear o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com