Gear processing micro cutting fluid

A kind of cutting fluid and micro-quantity technology, applied in the petroleum industry, lubricating composition, etc., can solve the problems of operators’ health hazards, processing site and environmental pollution, waste of mechanical oil, etc., achieve good corrosion resistance, save usage, prevent The effect of solution deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

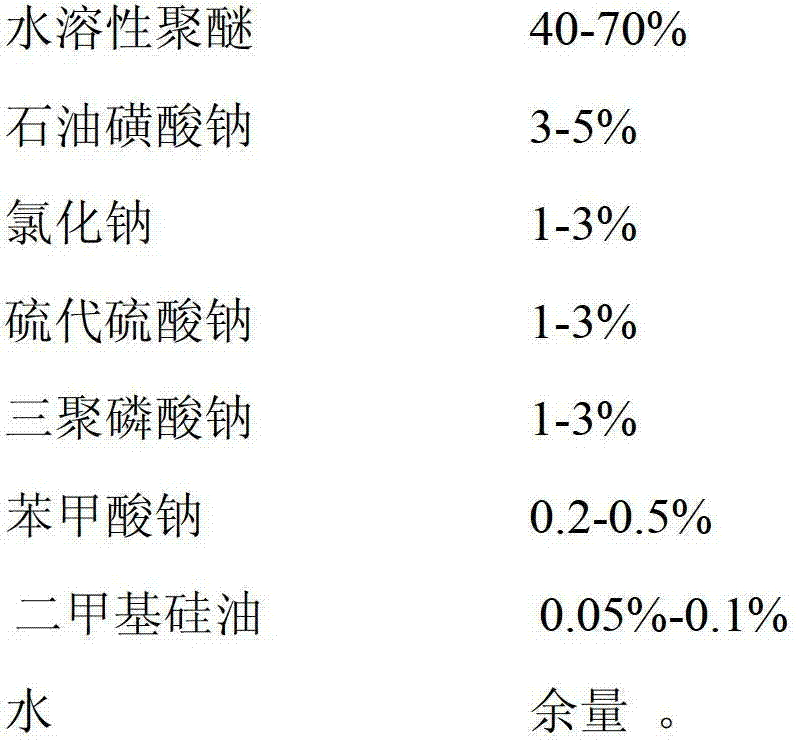

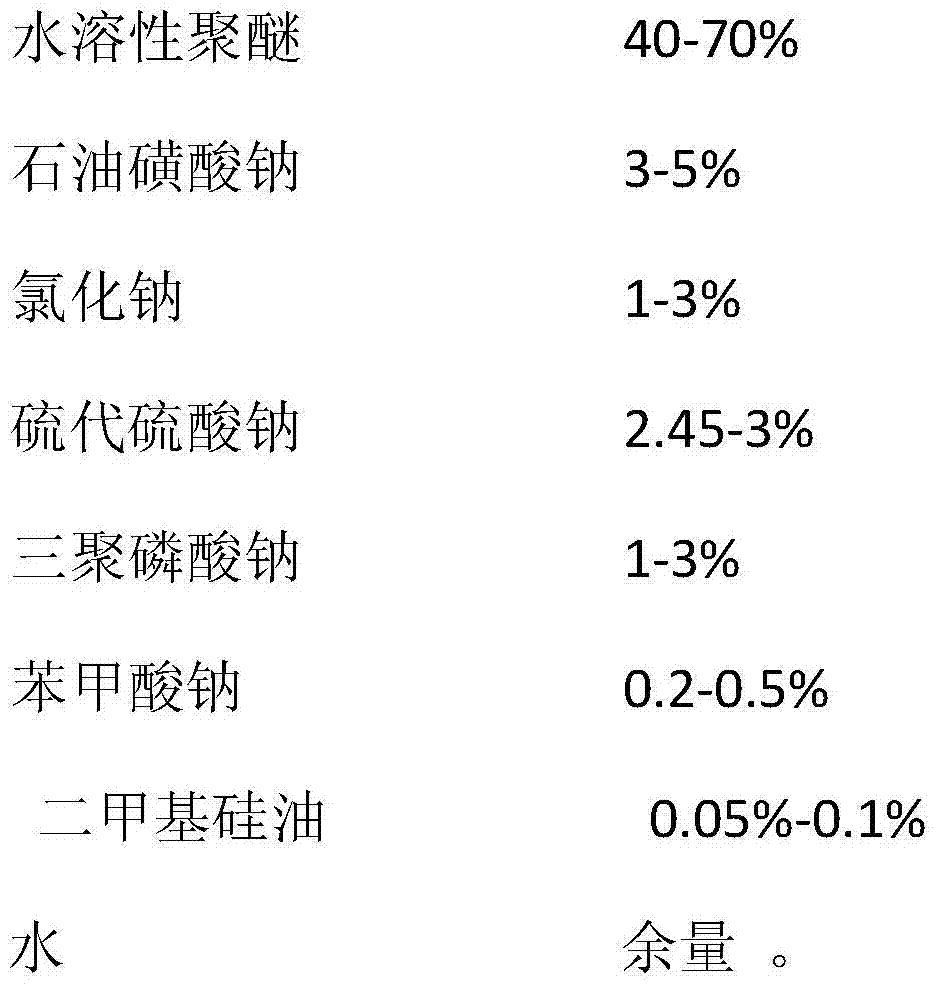

Method used

Image

Examples

Embodiment 1

[0024] Prepare the micro-cutting fluid for gear machining as follows:

[0025] 1. Add 40 kilograms of Breox 50A-140 water-soluble polyether, 4 kilograms of petroleum sodium sulfonate, and 0.1 kilograms of dimethyl silicone oil into the mixer and stir evenly; 2. Add 3 kilograms of sodium chloride and 3 kilograms of thio Sodium sulfate, 1.7 kilograms of sodium tripolyphosphate, and 0.2 kilograms of sodium benzoate were added to the weighed 48 kilograms of water and stirred uniformly; 3. Add the uniformly stirred liquid in 2 to the liquid in 1 and mix and stir for about 60 minutes. Sampling and observation, and packaging after being completely transparent.

Embodiment 2

[0027] Prepare the micro-cutting fluid for gear machining as follows:

[0028] 1. Add 50 kilograms of Henuvarox B20-150 water-soluble polyether, 3 kilograms of sodium petroleum sulfonate, and 0.08 kilograms of dimethyl silicone oil into the mixer and stir evenly; 2. Add 2 kilograms of sodium chloride and 1.6 kilograms of thio Sodium sulfate, 1 kg of sodium tripolyphosphate, and 0.32 kg of sodium benzoate were sequentially added to 42 kg of water and stirred uniformly; 3. Add the uniformly stirred liquid in 2 to the liquid in 1 and mix and stir for about 60 minutes. Sampling and observation, and packaging after being completely transparent.

Embodiment 3

[0030] Prepare the micro-cutting fluid for gear machining as follows:

[0031] 1. Add 54 kg of EmkaroxVG130W water-soluble polyether, 5 kg of sodium petroleum sulfonate, and 0.1 kg of dimethyl silicone oil into the mixer and stir evenly; 2. Add 1.5 kg of sodium chloride, 2 kg of sodium thiosulfate, Add 3 kilograms of sodium tripolyphosphate and 0.4 kilograms of sodium benzoate to the weighed 34 kilograms of water and stir well; 3. Add the uniformly stirred liquid in 2 to the liquid in 1 above and mix and stir for about 60 minutes, take a sample and observe, Pack after being completely transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com