Lubricating system for universal double-swing head of large-scale numerical control machining center

A machining center and lubrication system technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of poor lubrication and cooling effects, large space size requirements, and affecting the overall processing speed and accuracy of CNC universal double swing heads and other problems, to achieve the effect of small installation space, reduce moment of inertia, and enhance market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

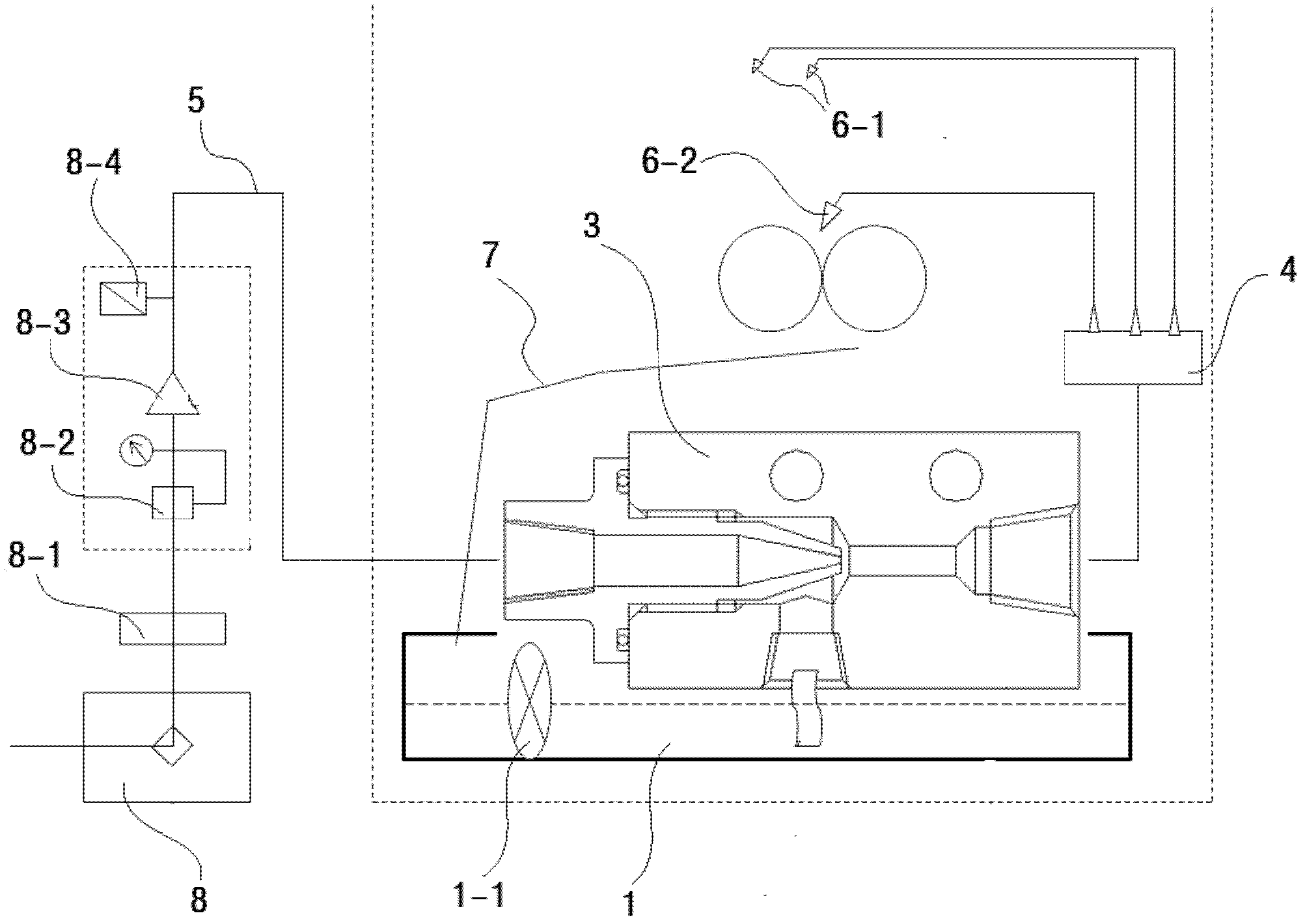

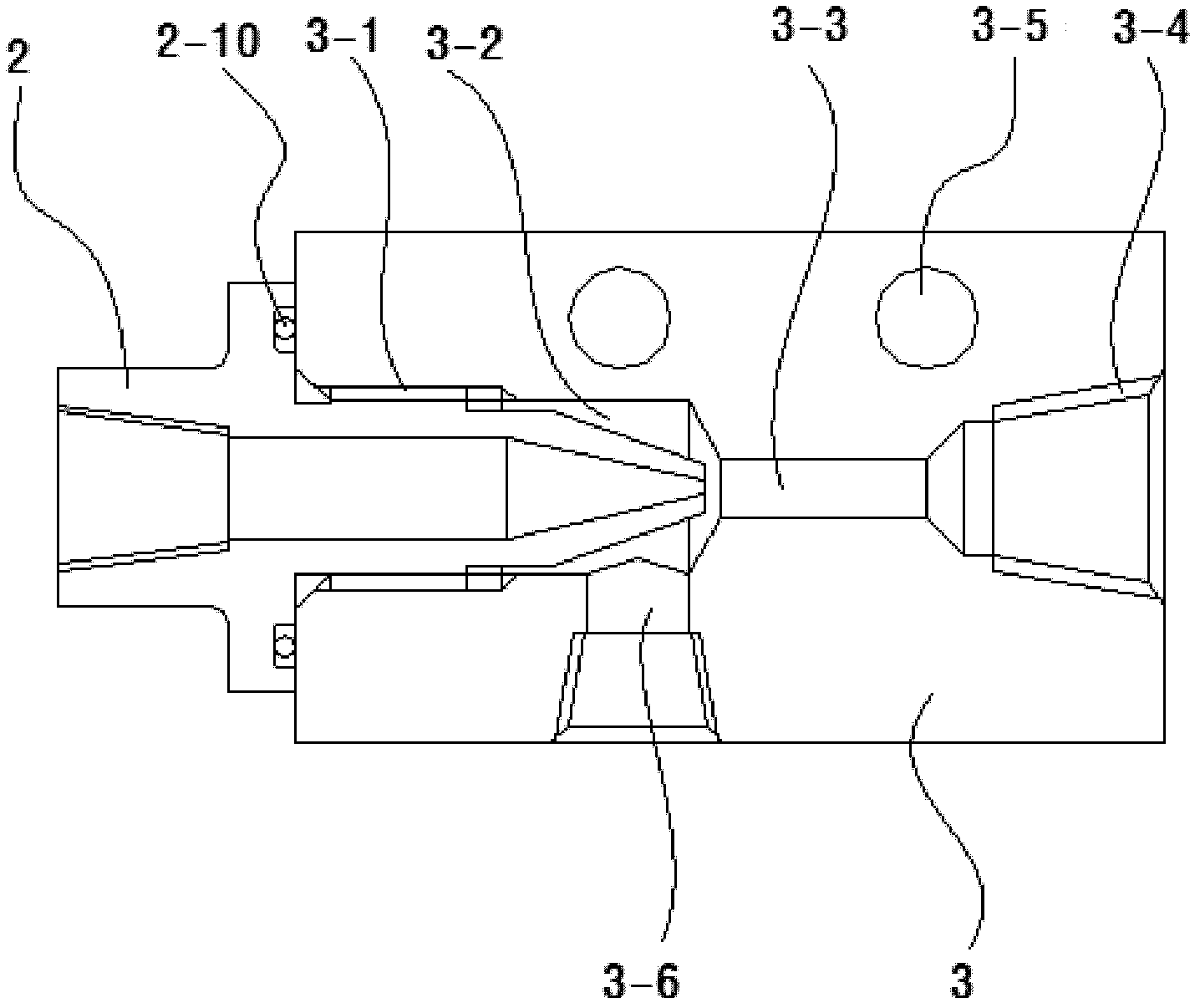

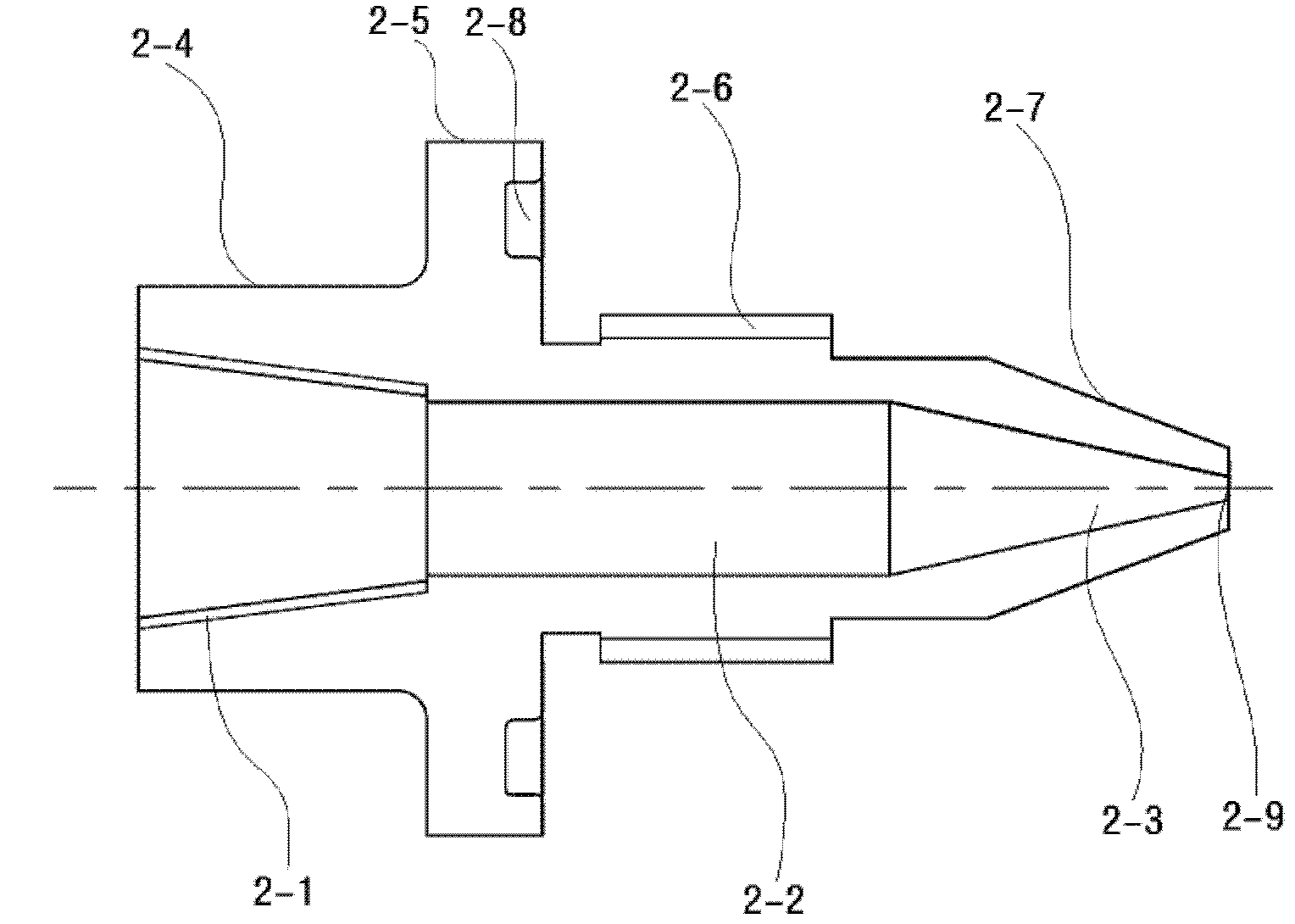

[0026] combine Figure 1-Figure 4 , a lubricating system for a universal double swing head of a large-scale CNC machining center, an external air source 8 and a built-in oil tank 1 are set, and the built-in oil tank 1 is fixed at the bottom of the inner cavity of the universal double swing head. The lubrication system is characterized in that It includes an oil and gas generating device and an oil and gas delivery device; the oil and gas generating device is composed of a compressed air nozzle 2 and an oil and gas mixing block 3, the compressed air nozzle 2 is a rotary body, and the hollow inner cavity is the inlet from the compressed air inlet to the outlet in turn Pipe 2-1, throat 2-2, conical nozzle cavity 2-3, the hollow cavity of the oil-gas mixing block 3 is the inlet cavity 3-1, vacuum chamber 3-2, diffusion Cavity 3-3, outlet cavity 3-4, the compressed air noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com