ESD protecting unit, array base plate, liquid crystal display panel and display device

An ESD protection and array substrate technology, applied in transistors, electrical components, optics, etc., can solve problems such as poor ESD protection effect, reduce the probability of breakdown, solve the problem of poor ESD protection effect, and reduce the effect of voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the ESD protection unit, the array substrate, the liquid crystal panel and the display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

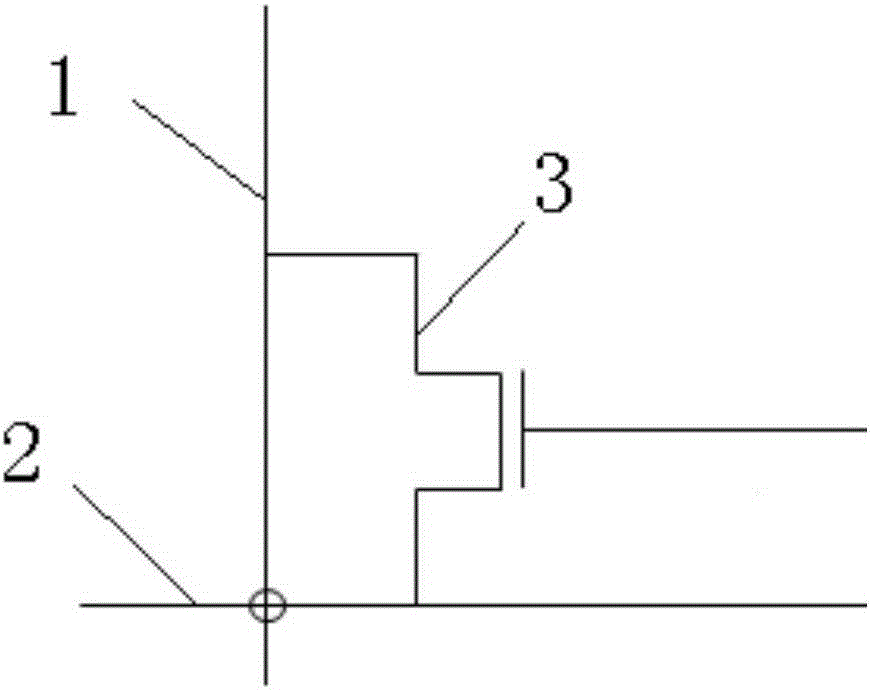

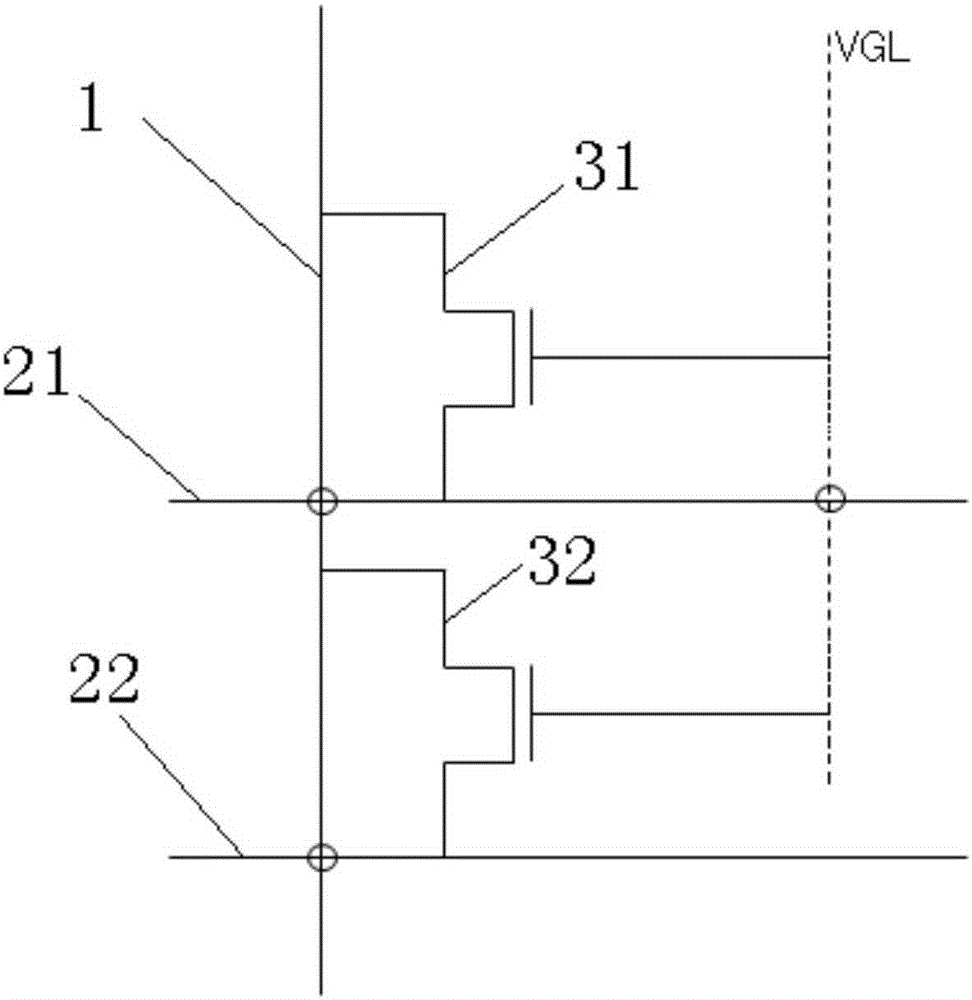

[0024] see figure 1 , the ESD protection unit provided by the embodiment of the present invention includes a thin film transistor 3, a first lead 1 and a second lead 2, and there is a voltage difference between the first lead 1 and the second lead 2; wherein, the source of the thin film transistor is connected to the second lead 2 One lead is connected, the drain of the thin film transistor is connected to the second lead, and the gate surface of the thin film transistor is exposed in the area corresponding to the pixel unit formed between the first lead 1 and the second lead 2, so as to collect the first lead 1 and the charge generated between the second lead 2.

[0025] Moreover, whether the first lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com