Application of two-dimensional lysozyme nano-film as photoresist

A two-dimensional nano, lysozyme technology, applied in the field of photoresist, can solve the problems of high operation requirements, harmful waste liquid, complicated steps, etc., and achieve the effects of low roughness, good resistance and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The application of lysozyme two-dimensional nano-film as a photoresist is as follows:

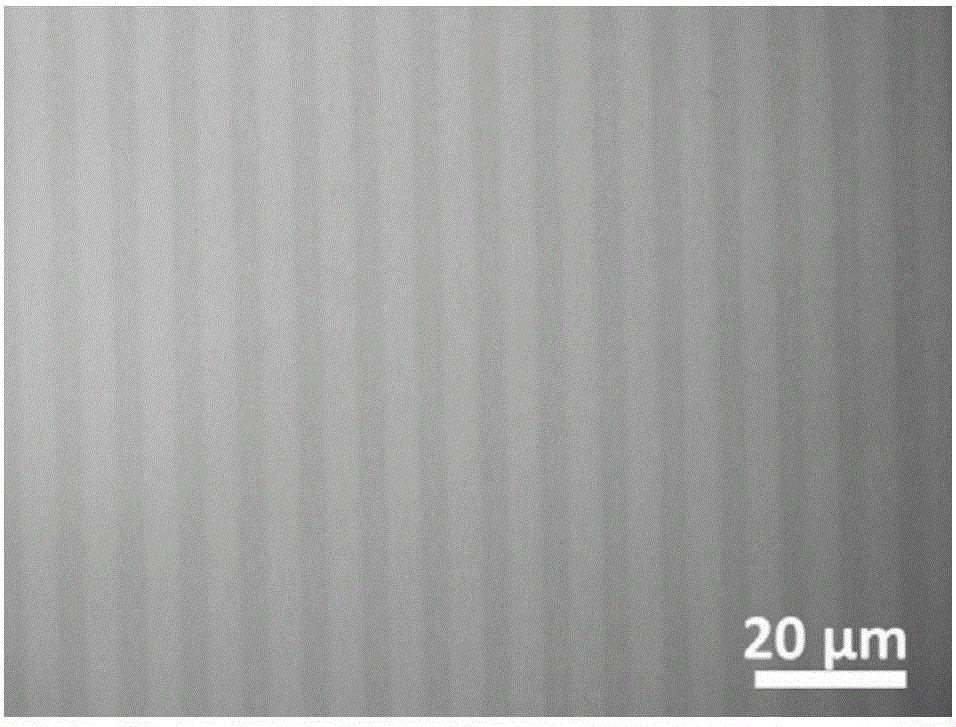

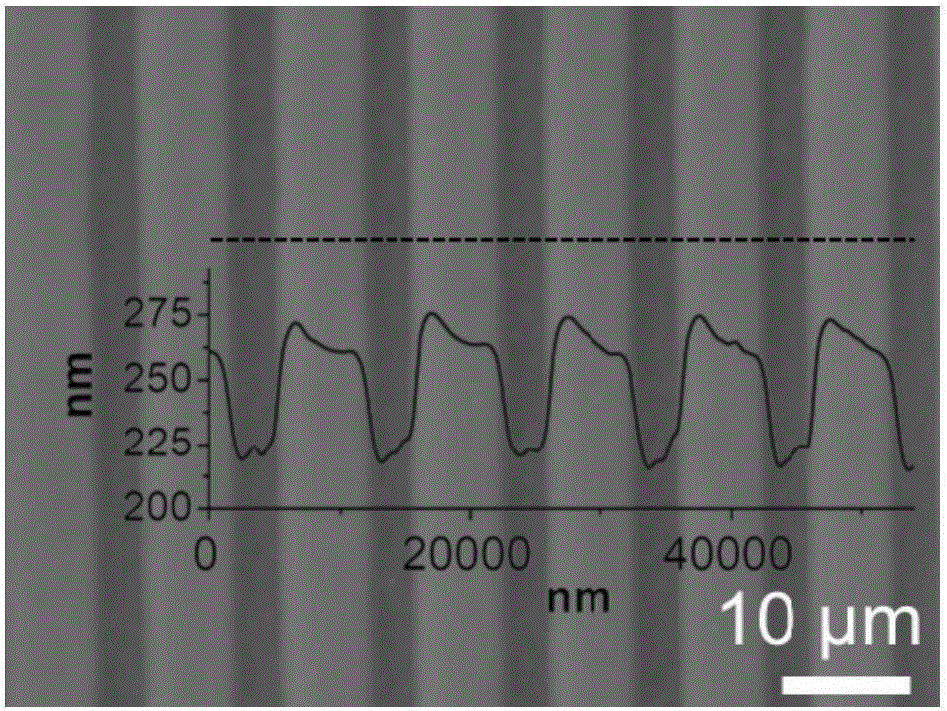

[0022] Place the silicon dioxide wafer with in situ growth of lysozyme two-dimensional nano-film on the surface between the photomask and the ITO glass plate, and place it under a high-pressure mercury lamp with an ultraviolet wavelength of 254nm and a light intensity of 8000μw / cm 2 Take it out after irradiating for 6 minutes under the same conditions, and develop it with ultrapure water for 30 seconds, as shown in figure 1 As shown, the two-dimensional nano-film of lysozyme has been patterned, that is, a silicon dioxide sheet covered with a patterned two-dimensional nano-film of lysozyme has been obtained. Add 5mL of isopropanol and 5mL of HF into the airtight container, then suspend the silicon dioxide wafer covered with the patterned lysozyme two-dimensional nano-film in the airtight container, and etch at 30°C with HF steam for 30 minutes at a constant temperature, and the etch...

Embodiment 2

[0024] The application of lysozyme two-dimensional nano-film as a photoresist is as follows:

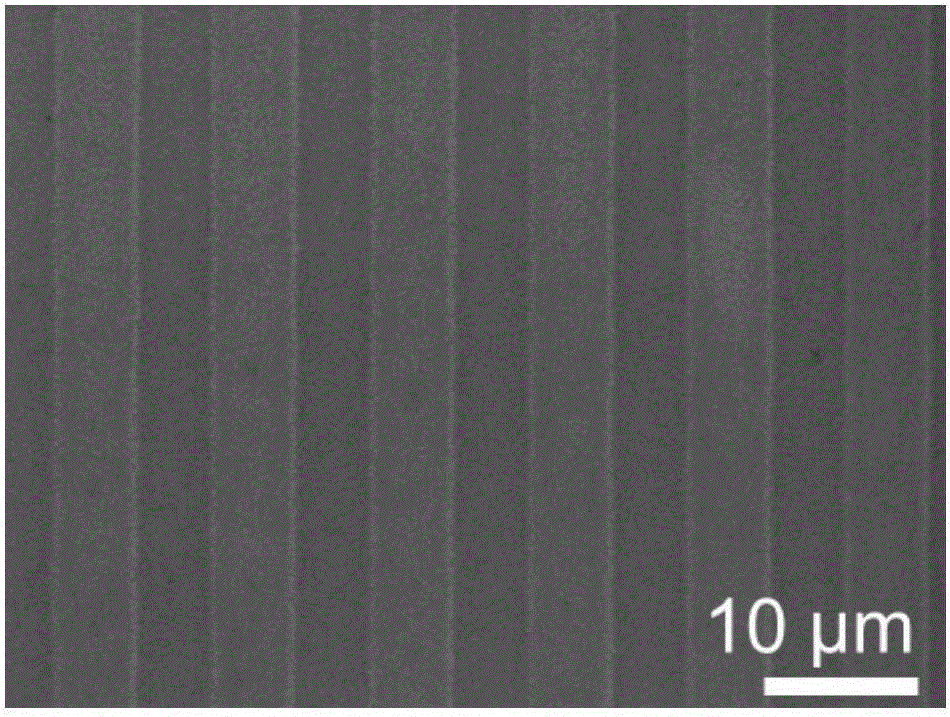

[0025] Place the copper-coated silicon chip with in-situ growth of lysozyme two-dimensional nano-film on the surface between the photomask and the ITO glass plate and fix it. Using the electron beam direct writing system, the acceleration voltage is 30kv, the electron beam spot is 3nm, and the electron beam The beam intensity is 3000μC / cm 2 Under the conditions of exposure, and then developed with ultrapure water for 30 seconds, such as Figure 4 As shown, the two-dimensional nanofilm of lysozyme has been patterned. Immerse the copper-plated silicon chip covered with the patterned lysozyme two-dimensional nano-film in 5mL aqueous solution containing 10mmol / L N-bromosuccinimide and 10mmol / L pyridine, etch at room temperature for 10 minutes, and then etched After the copper-plated silicon chip is placed in the mass fraction of 50% acetic acid aqueous solution for 10 minutes, the patt...

Embodiment 3

[0027] The application of lysozyme two-dimensional nano-film as a photoresist is as follows:

[0028] Place the copper-coated silicon wafer with in-situ growth of lysozyme two-dimensional nano-film on the surface between the photomask and the ITO glass plate, and place it under a high-pressure mercury lamp, with an ultraviolet wavelength of 254nm and a light intensity of 8000μw / cm 2 Take it out after irradiating for 6 minutes under the condition, and develop it with ultrapure water for 30 seconds, and the lysozyme two-dimensional nano film has been patterned. Immerse the copper-plated silicon chip covered with the patterned lysozyme two-dimensional nano-film in 5mL aqueous solution containing 10mmol / L N-bromosuccinimide and 10mmol / L pyridine, etch at room temperature for 10 minutes, and then etched After the copper-plated silicon chip is placed in the mass fraction of 50% acetic acid aqueous solution for 10 minutes, the patterned copper-plated silicon chip (such as Image 6...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap