A magnetic composite microsphere with multi-level structure and its preparation method

A technology of magnetic composite microspheres and microspheres, applied in the field of nanomaterials, can solve the problems of low density, high difficulty, and improved wave absorbing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

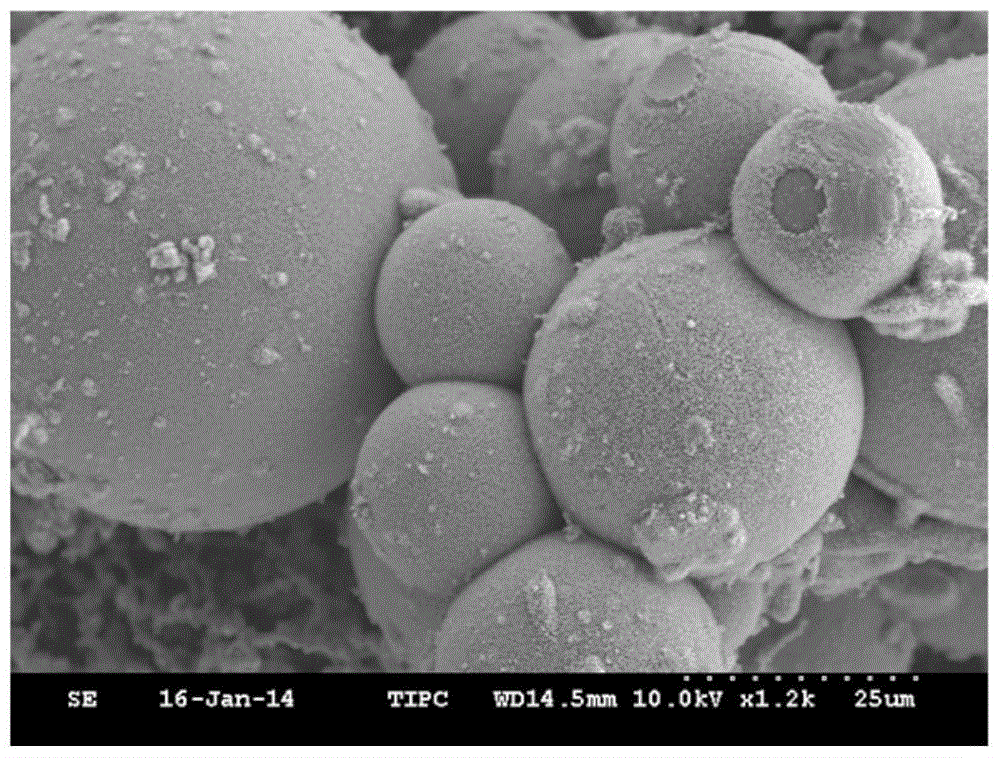

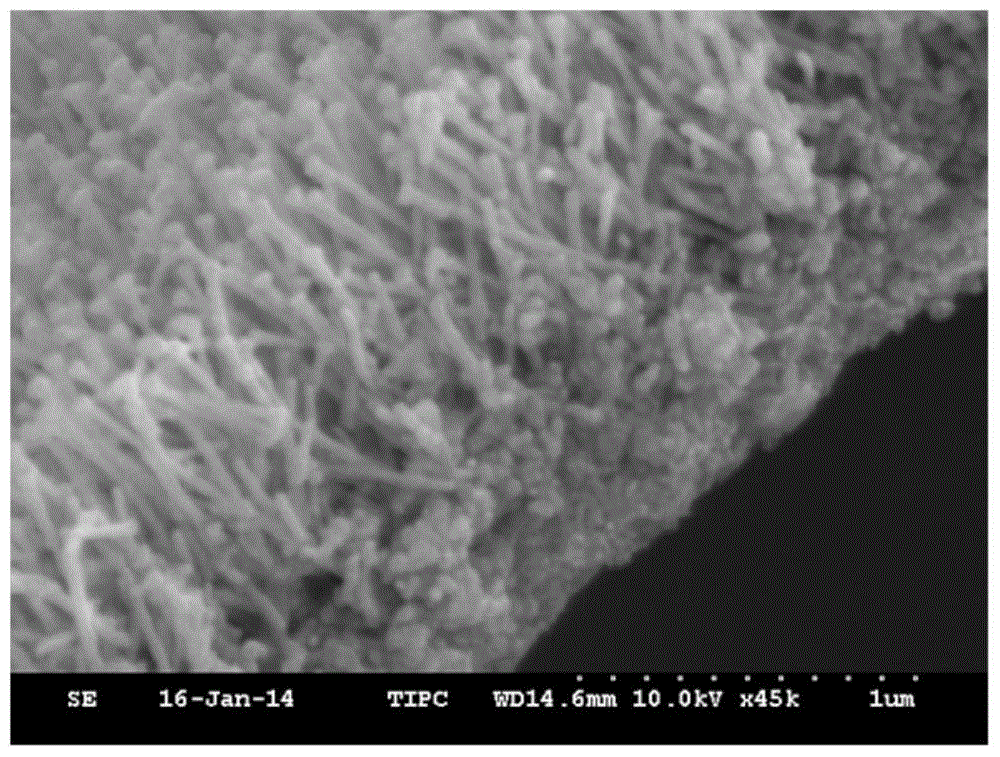

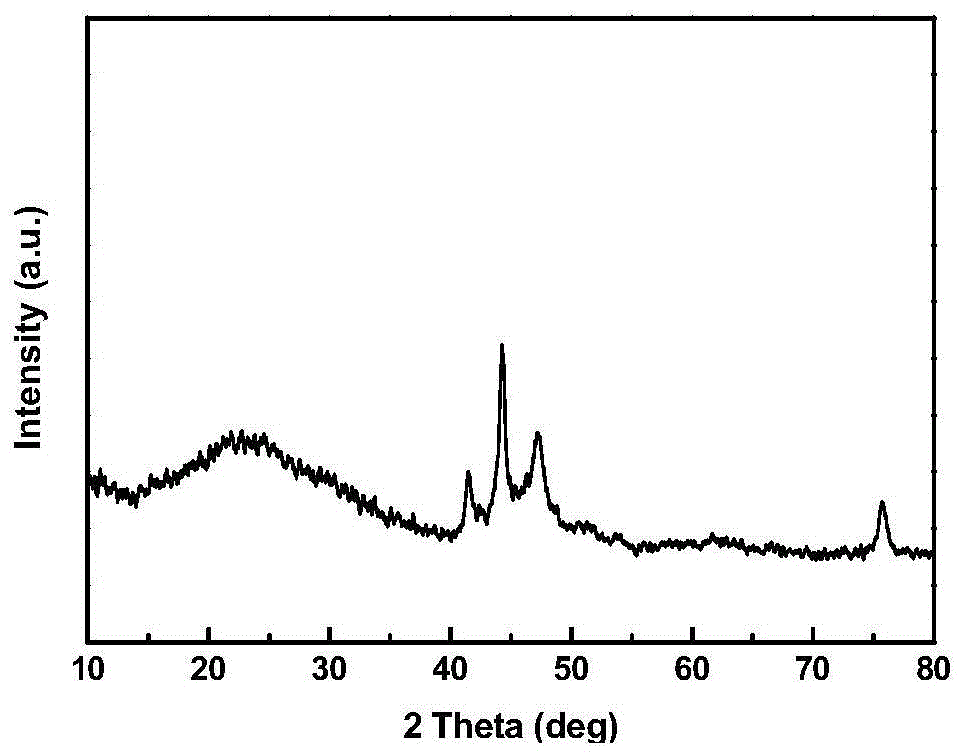

Embodiment 1

[0046]Use 0.5g of hollow glass microspheres with a particle size of 30-200μm as the substrate, aminopropyltriethoxysilane as the coupling agent, and react at 40°C for 10h in an aqueous solution of the coupling agent with a concentration of 0.1%. , filtered, washed and dried. Then, the coupled hollow glass microspheres were put into an aqueous solution of nano-palladium with a concentration of 0.5 g / L, and reacted at 40° C. for 30 min. After the reaction, filter and wash with water three times to obtain hollow glass microspheres loaded with seed metal palladium. Add the hollow glass microspheres loaded with seed metal palladium with 0.2g of nickel chloride, 0.8g of cobalt chloride, and 6.0mg of palladium chloride into 30g of ethylene glycol, and mix well. After the metal salt is fully dissolved, the mixed solution Add it to the polytetrafluoroethylene lining of the stainless steel reactor and seal it. The reaction kettle was placed in an oven at 140°C and reacted for 8 hours....

Embodiment 2

[0048] Use 0.5 g of hollow ceramic microspheres with a particle size of 40-100 μm as the substrate, aminopropyltriethoxysilane as the coupling agent, and react at 70 ° C for 1 h in a 2% coupling agent aqueous solution , filtered, washed and dried. Then, put the coupling-treated hollow ceramic microspheres into an aqueous solution of gold nanoparticles with a concentration of 2.0 g / L, and react at 70° C. for 240 min. After the reaction, filter and wash with water three times to obtain hollow ceramic microspheres loaded with seed metal gold. The hollow ceramic microspheres loaded with seeds are added to 30 g of 1,2-propylene glycol with 0.15 g of cobalt acetate and 7.5 mg of chloroauric acid, and mixed evenly. After the metal salt is fully dissolved, the mixed solution is added to the poly Teflon lined, sealed. The reaction kettle was placed in an oven at 200°C and reacted for 0.5h. The floating product was separated, washed with ethanol, filtered and dried to obtain magnetic...

Embodiment 3

[0050] Use 0.5g of hollow polyacrylic resin microspheres with a particle size of 1-80 μm as the substrate, and use mercaptopropyltrimethoxysilane as the coupling agent, and react at 50°C in a 1% coupling agent aqueous solution 4h, filter, wash and dry. Then, the coupled hollow microspheres were put into an aqueous solution of nano-ruthenium with a concentration of 1.0 g / L, and reacted at 50° C. for 120 min. After the reaction, filter and wash with water three times to obtain hollow microspheres loaded with seed metal ruthenium. Add the hollow microspheres loaded with seeds with 2.0g of cobalt nitrate, 1.0g of nickel acetate, and 15mg of silver nitrate into 30g of 1,3-propanediol and mix well. After the metal salt is fully dissolved, add the mixture to the stainless steel reaction kettle Teflon liner, sealed. The reaction kettle was placed in an oven at 100°C and reacted for 48 hours. The floating product was separated, washed with ethanol, filtered and dried to obtain magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com