Three-station switch release mechanism and method

A technology of three-position switch and release mechanism, which is applied in the direction of contact drive mechanism, air switch parts, etc., to achieve the effect of reducing friction and reducing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

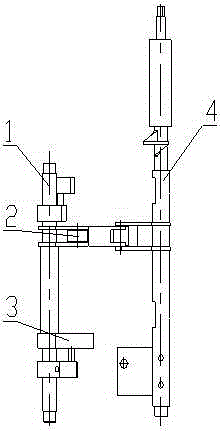

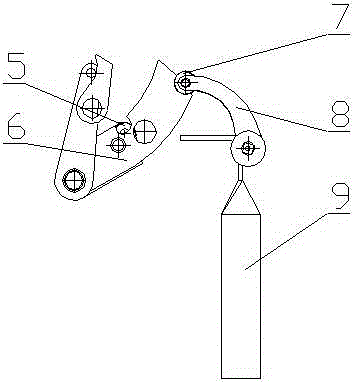

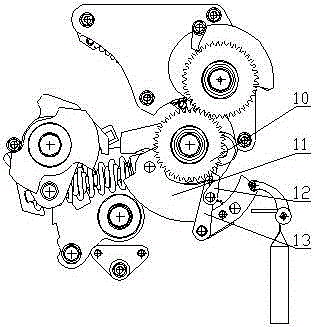

[0022] Such as Figure 1~4 As shown, with reference to the accompanying drawings, a release mechanism device of a three-position switch operating mechanism of the present invention includes a release shaft 1 and a control shaft 4, and the front limit swing rod 6 and the rear limit swing rod of the release shaft 1 3. A shift fork is provided on the side of the downward pressure spring bracket 11 facing the release shaft 1 .

[0023] During the three-station closing process, the limit roller 2 of the front limit swing lever 6 of the release shaft, the limit roller 5 of the rear limit swing lever 3, and the edge of the fork of the lower spring bracket 11 are kept in contact with each other. touch. The front limit swing link 6 of the release shaft 1 stores energy in the down-press spring when the down-press spring is compressed to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com