Rotary wafer de-waxing equipment

A rotary wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems that the wafer surface wax cannot be completely removed, the wafer is unevenly heated, and affects normal use, etc., to improve the wax removal effect, Uniform heating and improved heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

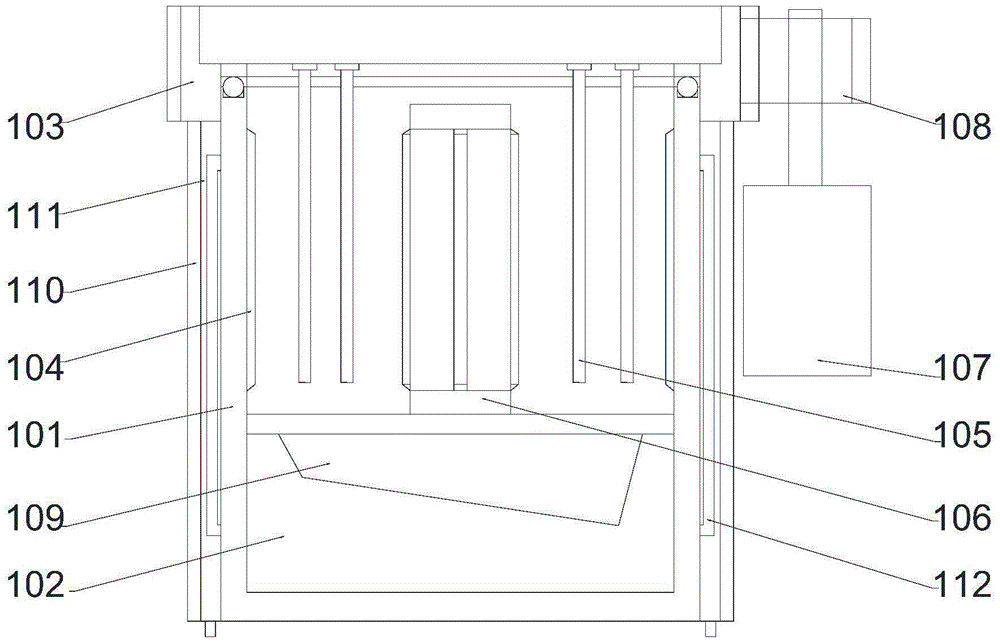

[0028] In order to achieve the effect of driving the movable end cover to rotate, in this embodiment, preferably, the driving device includes a driving motor 107 and a transmission gear 108 arranged on the output shaft of the driving motor 107, and the transmission gear 108 is connected to the The teeth on the movable end cap 103 are meshed.

[0029] In order to reduce the friction between the movable end cover and the upper end surface of the heating chamber, in this embodiment, preferably, balls are provided on the upper end surface of the heating chamber 101, and the rotating end cover 103 is opposed to the The heating bin 101 rotates horizontally.

[0030] In order to avoid heat loss, in this embodiment, preferably, an insulation layer 110 is provided outside the heating chamber 101, and a temperature control cavity 111 is formed between the outer wall of the heating chamber 101 and the insulation layer 110. .

[0031] In order to facilitate timely cooling of the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com