electrical connector

A technology for electrical connectors and contact parts, applied in the direction of contact parts, etc., can solve the problems of easy bending deformation or displacement, insufficient strength, and reduce costs, and achieve the effects of reducing processes, improving manufacturing capacity, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

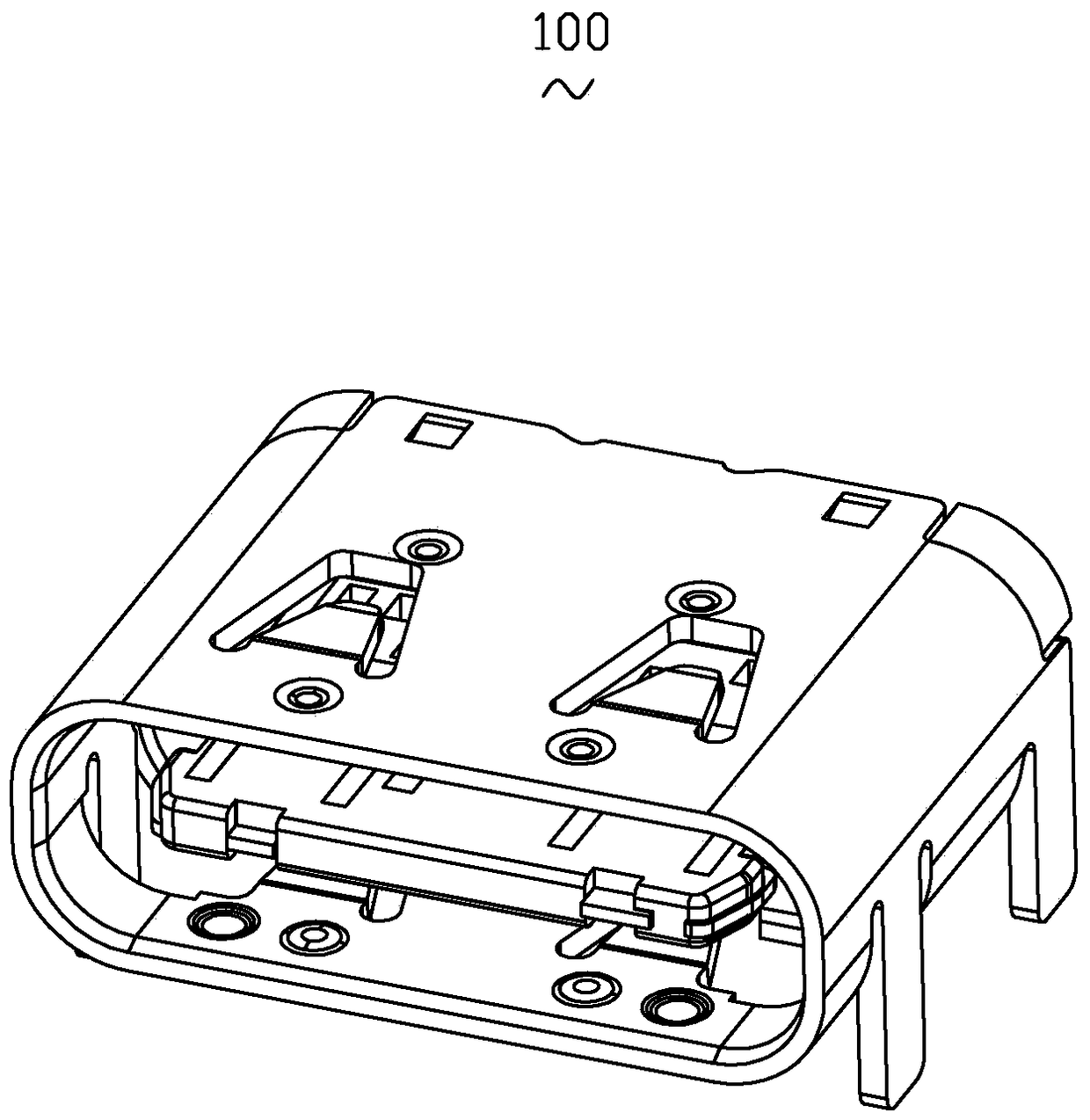

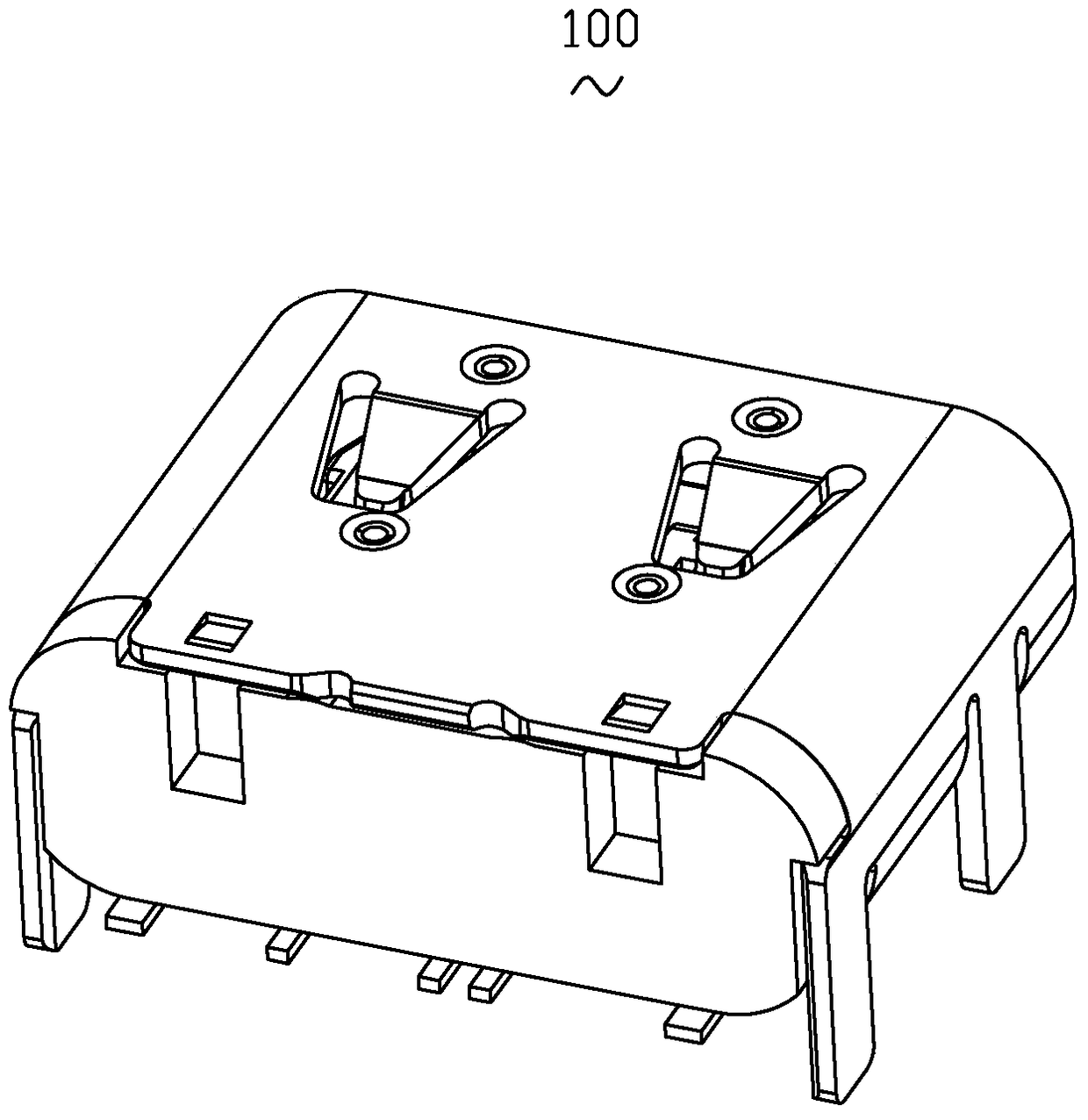

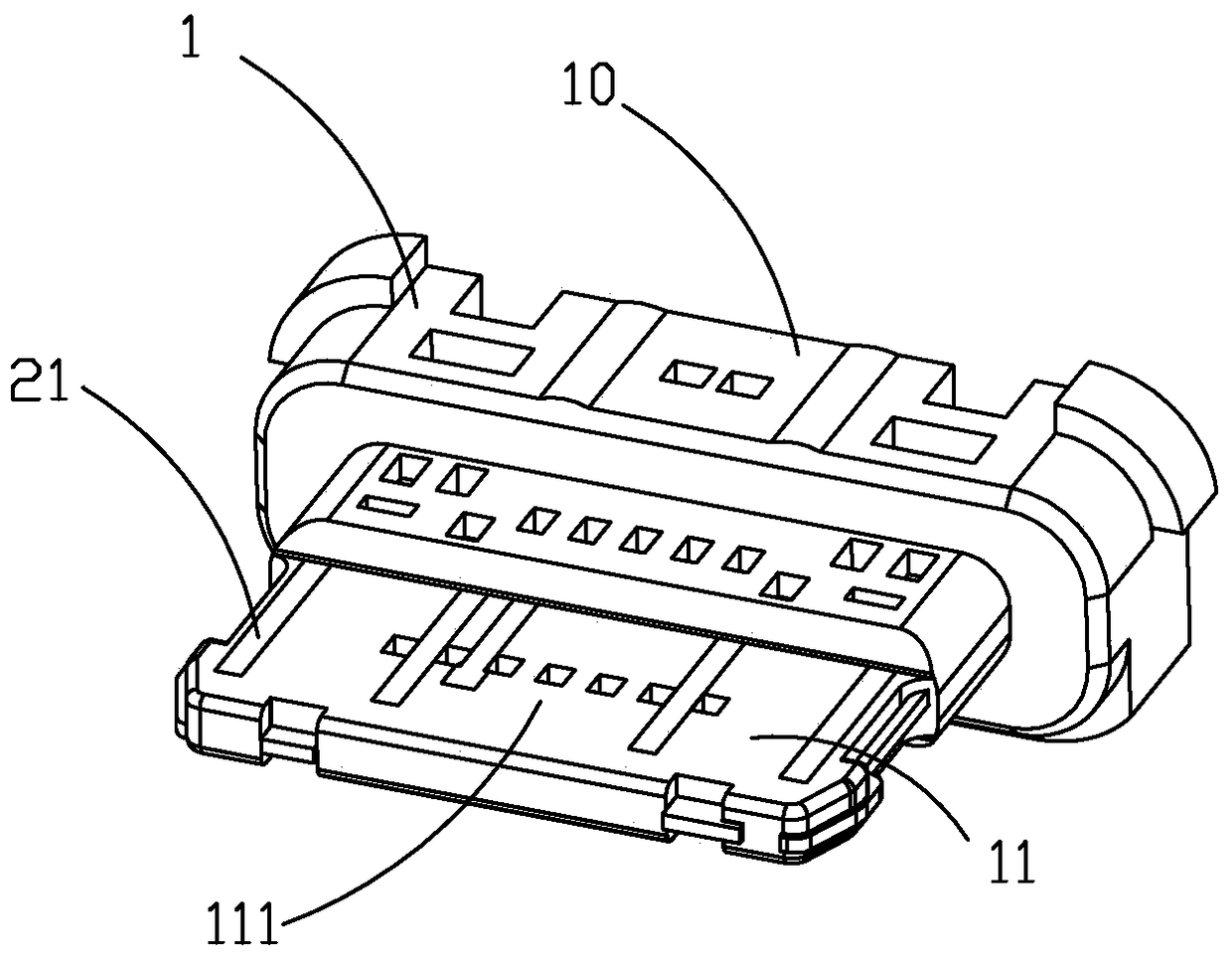

[0052] Please refer to Figures 1 to 7 As shown, it is the electrical connector 100 of the first embodiment of the present invention, the electrical connector 100 is a USB2.0 electrical connector 100 suitable for the interface frame of USB3.1 Type-C, that is, it does not include two pairs High-speed differential signal terminal (not shown). In other implementation manners, the electrical connector 100 may also be a standard USB3.1 Type-C connector including the two pairs of high-speed differential signal terminals.

[0053]In this embodiment, the electrical connector 100 includes an insulating body 1 and a conductive terminal group 2 installed on the insulating body 1. The insulating body 1 includes a base 10 and a tongue 11 extending forward from the base 10. The tongue plate 11 is provided with an upper surface 111 and a lower surface 112, the conductive terminal group 2 includes a first terminal 21, and the first terminal 21 is used for embedded molding on the insulating b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap