Motor stator automatic paint removal machine

A motor stator and automatic technology, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of affecting the quality and performance of the motor, the rotor is easy to rub and heat, and the labor intensity is high, so as to achieve the effect of reducing the labor intensity of paint removal, compact structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

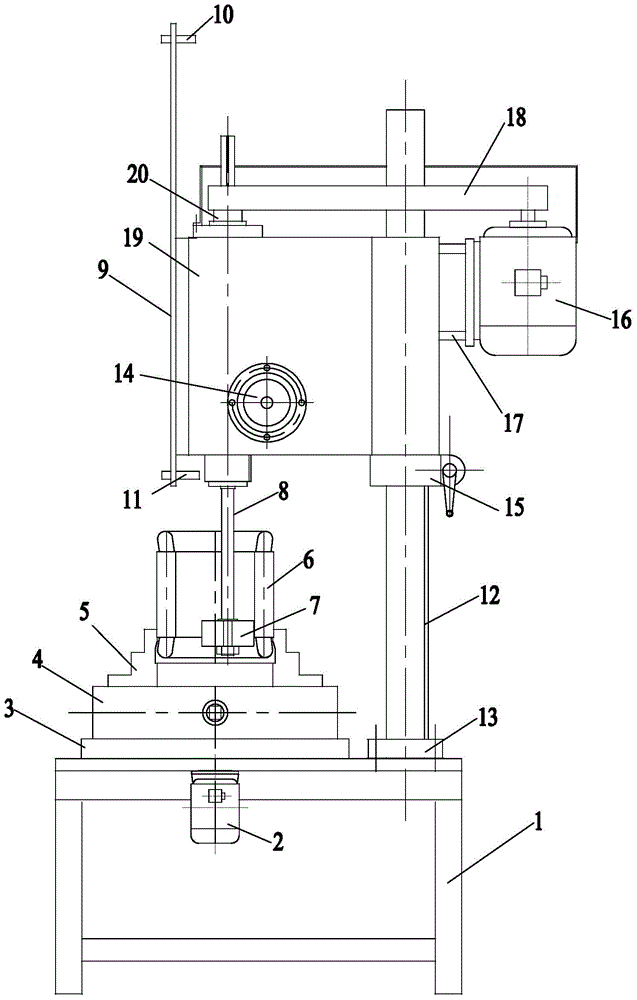

[0014] Such as figure 1 Shown: in order to realize the effective paint removal of the motor stator 6, improve the paint removal efficiency, and reduce the labor intensity of paint removal, the present invention includes a machine base 1 and a rotating disk 3 positioned on the machine base 1 for supporting the motor stator 6 , a vertically distributed main shaft support rod 12 is arranged on the base 1, a main shaft head 19 is arranged on the main shaft support rod 12, and the main shaft head 19 can move vertically on the main shaft support rod 12, The connecting rod 8 for installing the wire brush 7 is provided on the main shaft head 19, and the connecting rod 8 for driving the rotation of the connecting rod 8 and the rotation for driving the main shaft head 19 to move on the main shaft supporting rod 12 are arranged on the main shaft head 19. Mobile drive mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com