Board inspection method

A substrate detection and substrate technology, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problem of not shortening the detection time, etc., and achieve the effect of simple and easy substrate detection, easy substrate detection, and reduced detection times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now, the best mode for carrying out the present invention will be described.

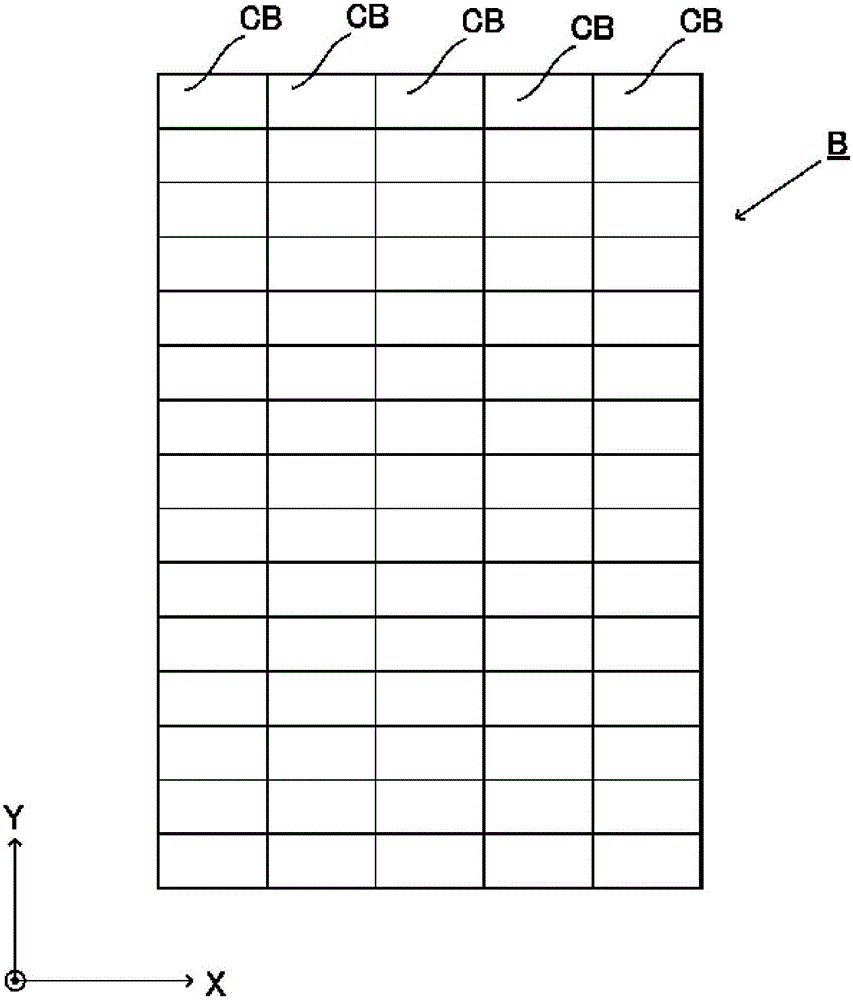

[0026] An object of the present invention is to efficiently perform detection of a sheet substrate B connected by a plurality of unit substrates CB on which one or more wiring patterns P having multiple terminals are formed. Therefore, the sheet substrate B to be detected will be described.

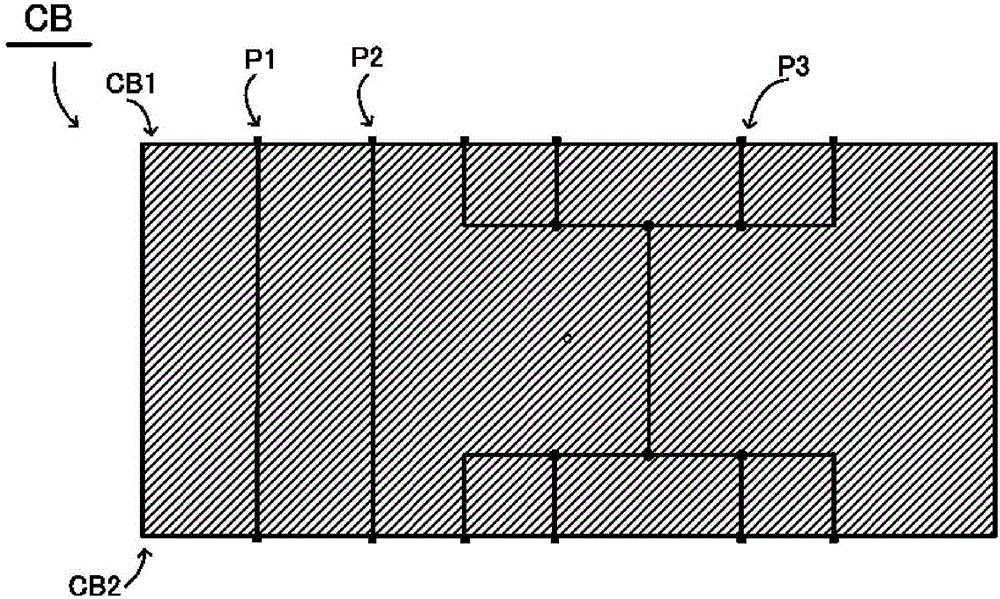

[0027] figure 1 One embodiment of the sheet substrate B is shown. figure 1 The illustrated sheet substrate B is formed in a sheet shape by arranging a plurality of unit substrates CB on which a plurality of wiring patterns are formed in a matrix. The substrate B, as figure 1 As shown, a plurality of unit substrates CB to be detected are formed in a matrix shape with multiple rows and multiple columns. This board|substrate B is divided into each unit board|substrate CB after detection processing etc. are performed. Each unit substrate CB is formed to have a plurality of similar wiring patterns. figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com