Denitration catalyst life whole-process management method

A technology for denitrification catalyst and catalyst life, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., to achieve the effect of safe treatment, good economy, and unique conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

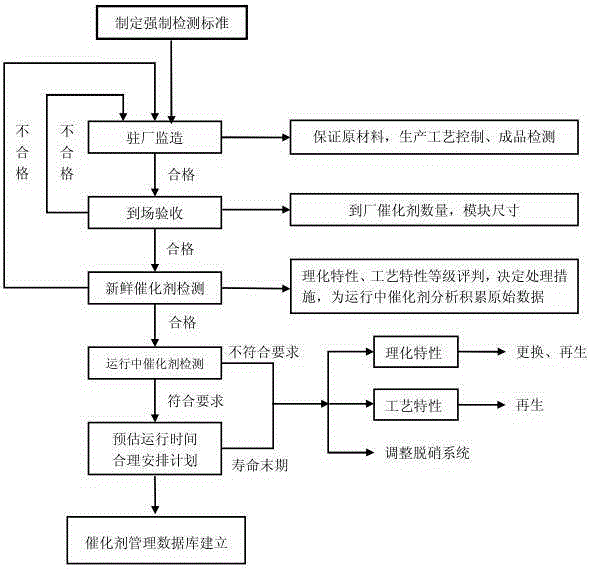

[0034] see figure 1 In this embodiment, the method for the whole process management of the denitrification catalyst life is described in detail by taking the A power plant project as an example, and the specific steps of the method are as follows.

[0035] The denitrification transformation project of power plant A determines that the denitrification process is SCR denitrification process, which requires the use of catalysts. For the smooth implementation of the project, while determining the transformation process, a catalyst life-cycle management plan was formulated to ensure that the production, commissioning, and final disposal of catalysts can be properly handled to prevent problems before they happen, and to ensure that power plant A can use catalysts with superior performance , without generating solid waste. After formulating the whole process management plan of catalyst life, the implementation process of the whole process management plan of catalyst life is establis...

Embodiment 2

[0042] see figure 1 , the steps of the method for the whole process management of the life of the denitration catalyst in this embodiment are as follows.

[0043] (1) Formulate a management plan for the whole process of catalyst life.

[0044] (2) Determine the catalyst manufacturer, appoint professionals to supervise and inspect the catalyst production process and product quality, and form a supervision and inspection report.

[0045] (3) For qualified catalyst products leaving the factory, entrust a third-party testing party to conduct random sampling performance testing of the catalysts to be put into operation, and issue a test report.

[0046] (4) Before the qualified catalyst products are put into use, the arrival inspection is carried out, and the acceptance report is formed, and then installed and put into operation.

[0047] (5) For catalysts that have been put into operation for a certain period of time, entrust a third party to conduct performance acceptance tests...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com