Perforating die for door guide rail

A technology for punching dies and door guide rails, applied in the field of stamping dies, can solve the problems of increased enterprise costs, low processing efficiency, and poor processing effects, and achieve the effects of eliminating hidden dangers of missed punching, improving work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

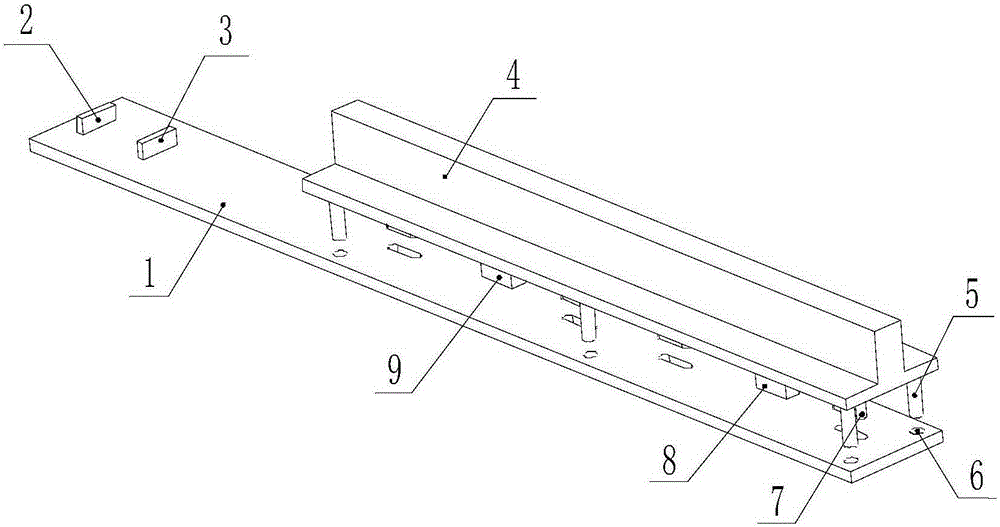

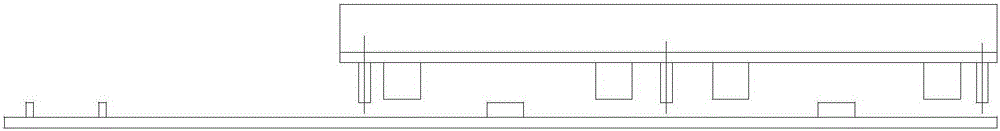

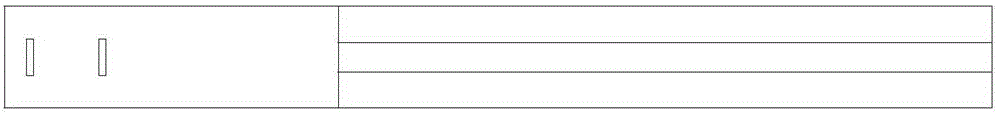

[0017] Examples such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a door guide rail punching die includes a lower die, a fixed backer, a movable backer, an upper die, a guide column, a guide hole, a stamping head, a left limit boss and a right limit boss; A fixed backer and a movable backer are installed on the surface near the left side. The movable backer is located on the right side of the fixed backer. The lower mold is provided with three sets of guide holes, each with two guide holes. The left limit The boss and the right limit boss are fixedly installed on the top surface of the lower die, and the bottom surface of the upper die is provided with three guide posts, and each group is provided with two guide posts, and the guide posts on the upper die are located on the lower die. Directly above the guide hole, four stamping heads are installed on the bottom surface of the upper die.

[0018] Preferably, both the fixed backing and the movable backing are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com