Steel tube cutting-off machine for manufacturing liquid storage device

A technology of cutting machine and liquid storage device, which is applied in the direction of manufacturing tools, pipe shearing devices, shearing devices, etc., can solve the problems of poor sanitary environment in the production workshop, increase the production cost of enterprises, hidden dangers of employee safety, etc., and increase the economic benefits of enterprises. , reduce production costs and ensure the effect of environmental sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

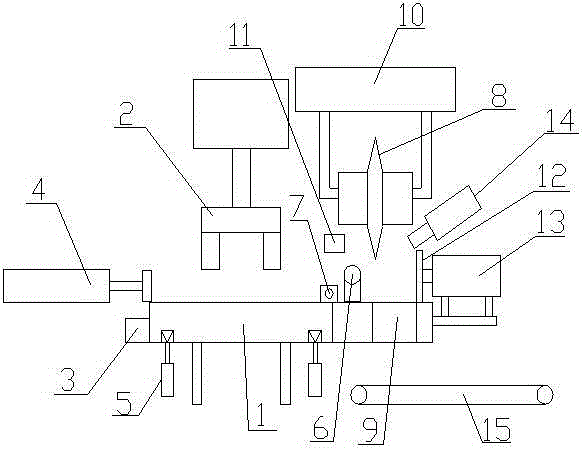

[0012] Such as figure 1 As shown, this embodiment provides a steel pipe cutting machine for manufacturing a liquid reservoir, including a steel pipe placement tank 1, a feeding manipulator 2 is arranged above the steel pipe placement tank 1, and the side of the steel pipe placement tank 1 is installed There is an excess material detector 3, a pushing cylinder 4 is installed on the left side, a jacking cylinder 5 is installed under the steel pipe placement tank 1, a placement table 6 is arranged on the right side of the steel pipe placement groove 1, and an infrared sensor 7 is arranged on the left side A rotary cutter 8 is provided above the placement table 6, and a feeding channel 9 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com