Hydraulic chain saw of deep sea manned submersible vehicle

A submersible and hydraulic technology, applied in the field of deep-sea manned submersible hydraulic chainsaw, can solve the problems of easy occurrence of danger, complicated operation, complicated structure, etc., and achieves improved accuracy and safety, flexible cutting operation, and simple transmission mechanism. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

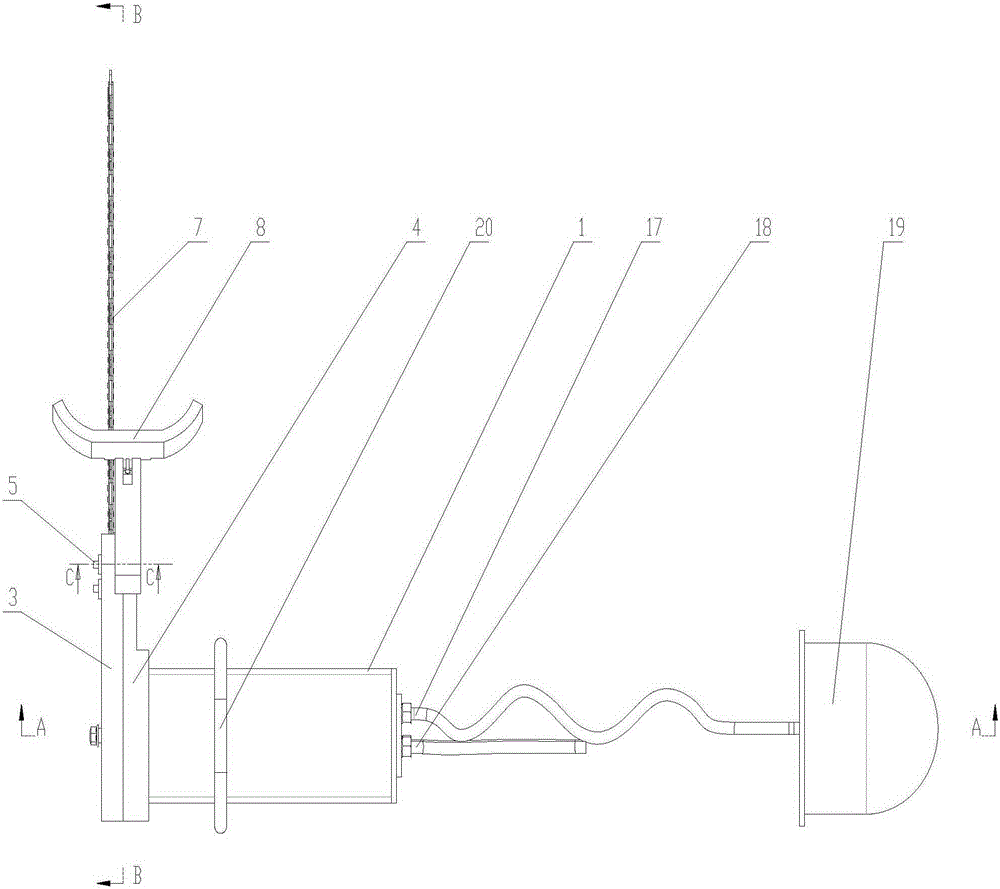

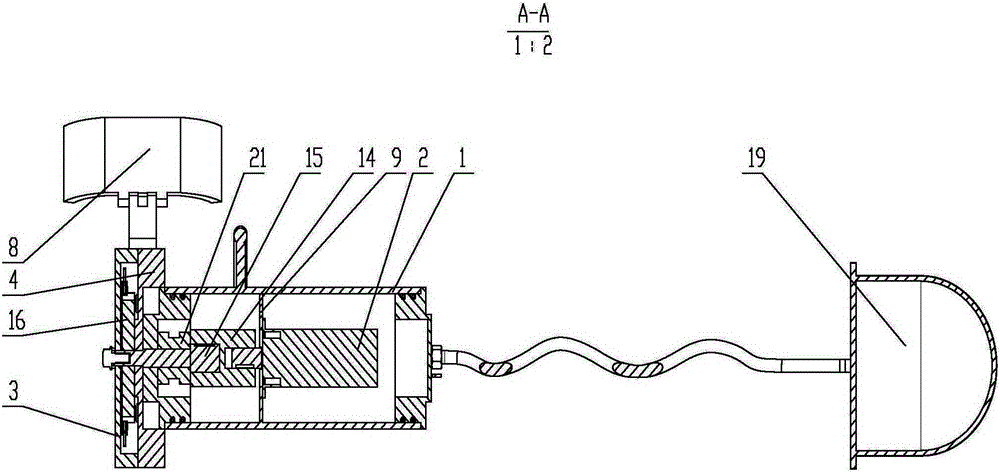

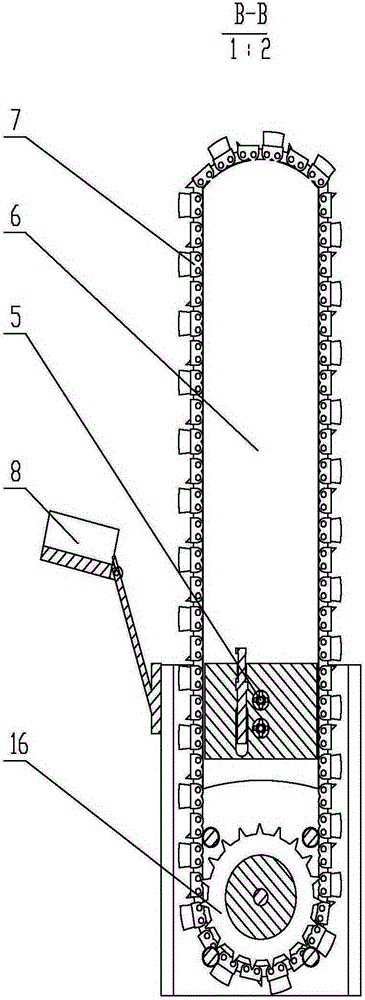

[0029] Such as figure 1 —— Figure 7 As shown, a hydraulic chainsaw for a deep-sea manned submersible mainly includes a sealed casing 1, a hydraulic motor 2, an upper baffle 3, a lower baffle 4, a key 5, a saw board 6, a cutting chain 7, and an anti-shock plate 8 , the hydraulic motor 2 is fixed inside the sealed casing 1 through the flange 9, and the upper and lower baffles are engaged and fixed at the front end of the sealed casing 1; the upper end of the inner wall of the lower baffle (4) is provided with a boss 23. There is a slot 22 on the boss 23, a chute I is opened on the upper end of the upper baffle plate 3, and a chute II is opened on the corresponding position of the saw board. Key I10, horizontal key II11, and horizontal key III12 are fixedly connected to spring 13 at the lower end of horizontal key III12; the key passes through chute I and chu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| torque | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com