A method for comprehensive utilization of chemical gypsum and carbide slag

A chemical gypsum, carbide slag technology, applied in chemical instruments and methods, inorganic chemistry, sulfur compounds, etc., can solve problems such as unreported, and achieve the effects of short process, improved sulfuric acid quality, and power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

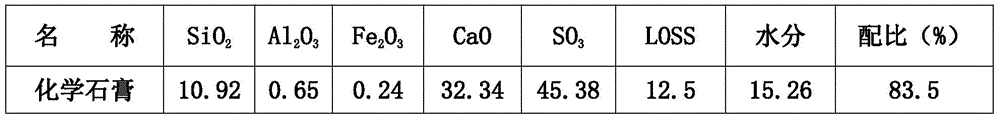

[0024] When the chemical gypsum used is piled in the slag yard and has relatively low water content, such as chemical gypsum with an external water content of 15.26% (see Table 1 for raw material composition), the lime saturation coefficient of the rotary kiln clinker is 0.90 The formula of ~0.94 requires calculation to obtain the ratio of various raw materials.

[0025] Table 1 Example 1 Raw material composition and clinker composition

[0026]

[0027]

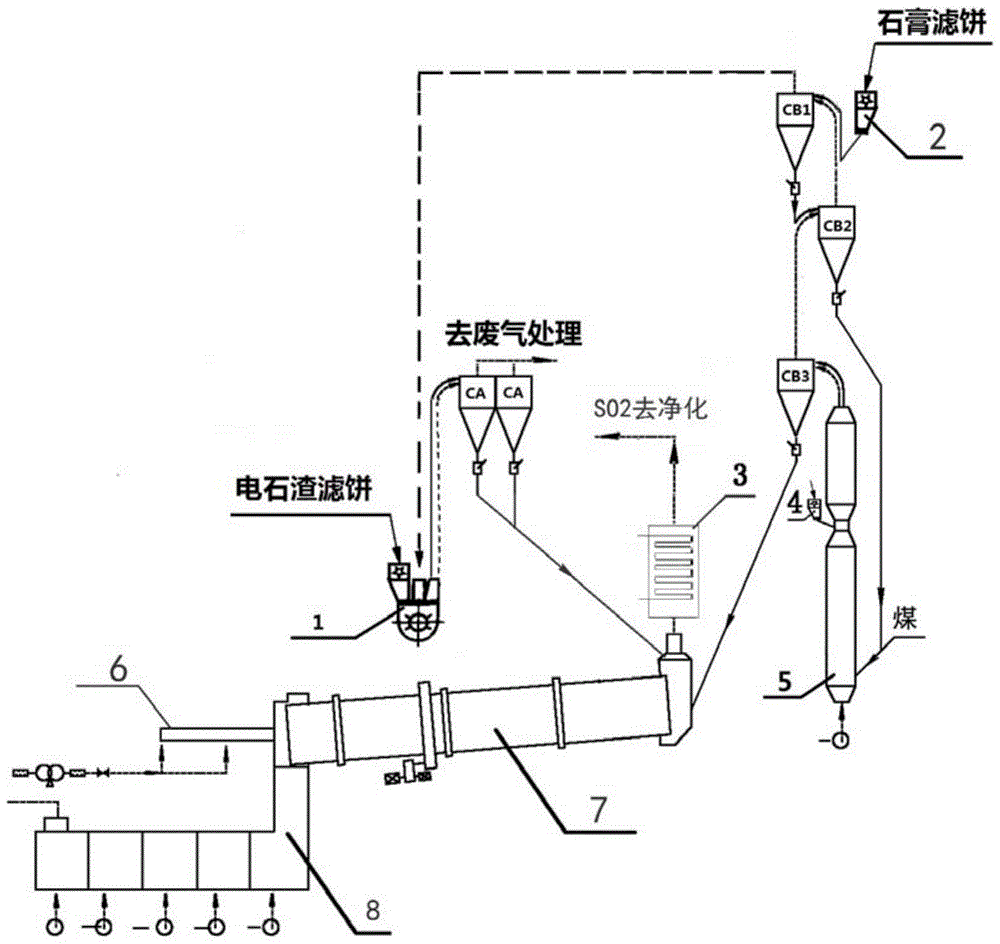

[0028] Such as figure 1 Shown: the gypsum raw material accounting for 53% of the total chemical gypsum is metered from the feeder 2 into the pipeline, and the heat is exchanged with the exhaust gas from the reduction furnace 5 through the cyclone preheater CB2 to be cooled to below 750°C. After the chemical gypsum is dried and dehydrated, it undergoes gas-solid separation through the cyclone preheater CB1. The separated material enters the inlet pipe of the next cyclone preheater CB2 to continue heating and dehydration. After the...

Embodiment 2

[0046] When the chemical gypsum raw material used is a wet-process phosphoric acid filter, such as phosphogypsum with a moisture content of 25.78% (see Table 2 for raw material composition), it can be calculated according to the formula requirement that the lime saturation coefficient of the rotary kiln clinker is 0.90~0.94 The ratio of various raw materials.

[0047] Table 2 Example 2 Raw material composition and clinker composition

[0048]

[0049]

[0050] Such as figure 1 As shown, the phosphogypsum, which accounts for 52% of the total phosphogypsum, is metered from the feeder 2 into the pipeline and exchanges heat with the exhaust gas from the reduction furnace 5 through the cyclone preheater CB2 to be cooled to below 660°C. After the phosphogypsum is dried and dehydrated, it undergoes gas-solid separation through the cyclone preheater CB1. The separated material enters the inlet pipe of the next cyclone preheater CB2 to continue heating and dehydration. After separation by t...

Embodiment 3

[0055] When the supply of hydrogen sulfide gas is insufficient or there is no hydrogen sulfide gas, the fuel added from the kiln fuel adding device 6 can use liquid sulfur as a supplementary or alternative fuel. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com