Main reducer assembly with two end input function

A main reducer and front-end input technology, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem that the input at one end of the main reducer assembly cannot meet the performance requirements, and achieve outstanding substantive features, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

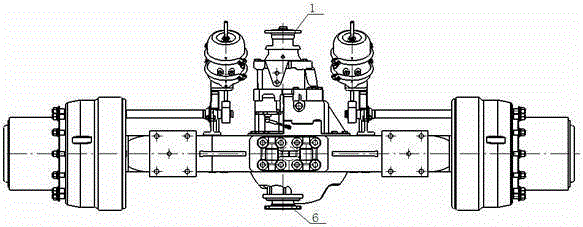

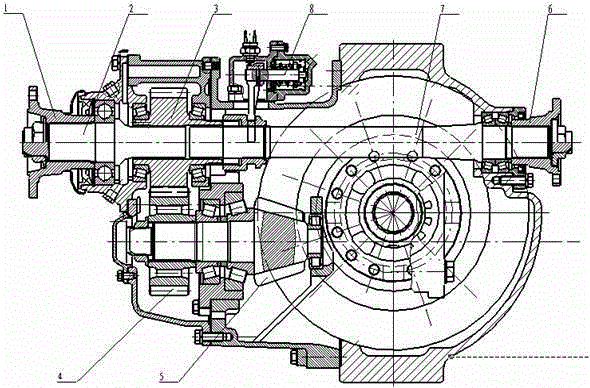

[0012] Example 1, see figure 1 , 2 , select the front input shaft 2 and the rear input shaft 7 of appropriate specifications, install the front input flange 1 outside the front end of the front input shaft 2, and install the rear input flange 6 outside the rear end of the rear input shaft 7; The front input shaft 2 is connected with the driving cylindrical gear 3 through a spline, and the driving cylindrical gear 3 meshes with the driven cylindrical gear 4 on the main cone 5, and finally the power is transmitted to the tire; the rear input shaft 7 is connected with the differential gear through a spline. The lock 8 is connected, the rear input shaft 7 is in contact with the driving cylindrical gear 3 through the shaft hole, and there is no rigid connection. When the differential lock 8 moves to the left, it can be connected with the driving cylindrical gear 3 and the rear input shaft through the spline at the same time. 7 are connected to each other to form the main reducer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com