Lubricating oil circuit system and planetary gear reducer for aircraft planetary gear reducer

A planetary gear deceleration, lubricating oil circuit technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, mechanical equipment, etc., can solve the problem of not centralized discharge of lubricating oil, pollution, etc., and achieve the maximum material and structure. effect of chemical utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

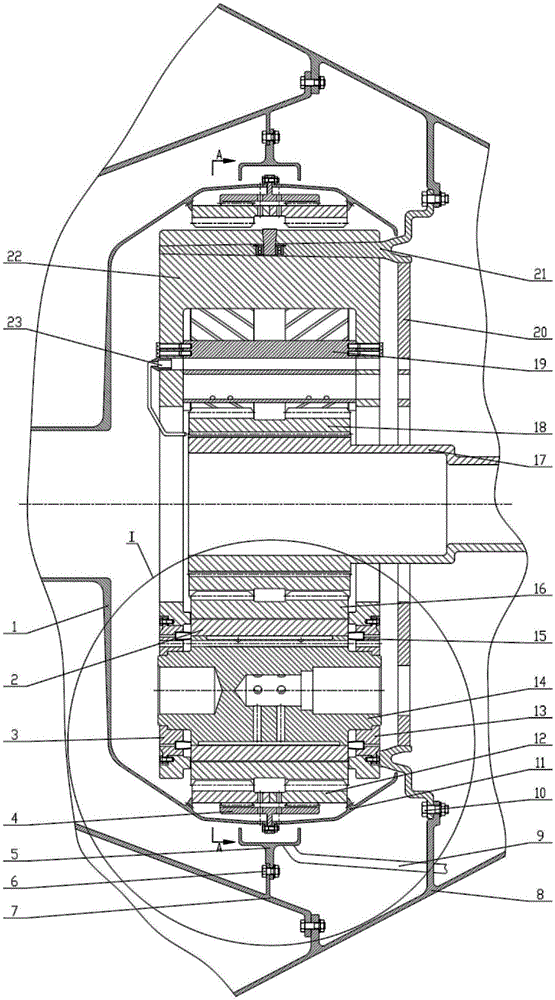

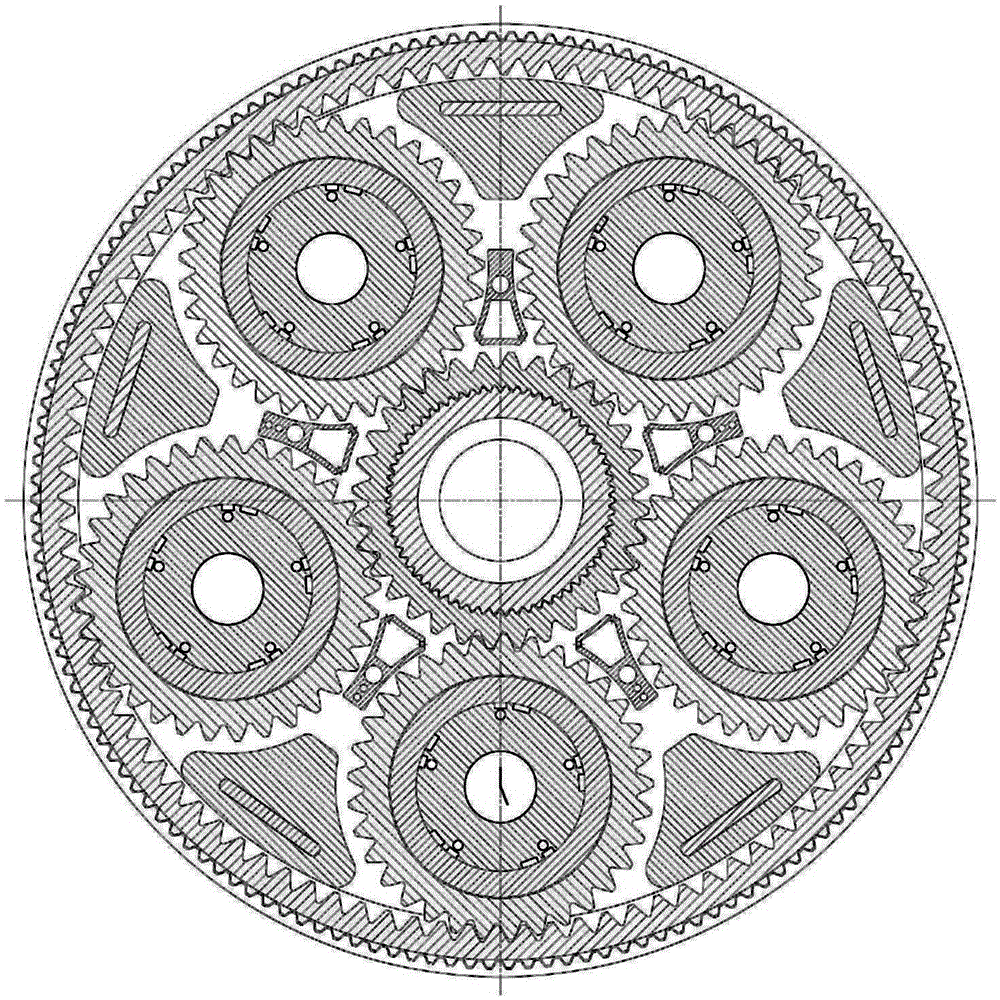

[0033] Example 1: Aircraft planetary gear reducer lubricating oil circuit system

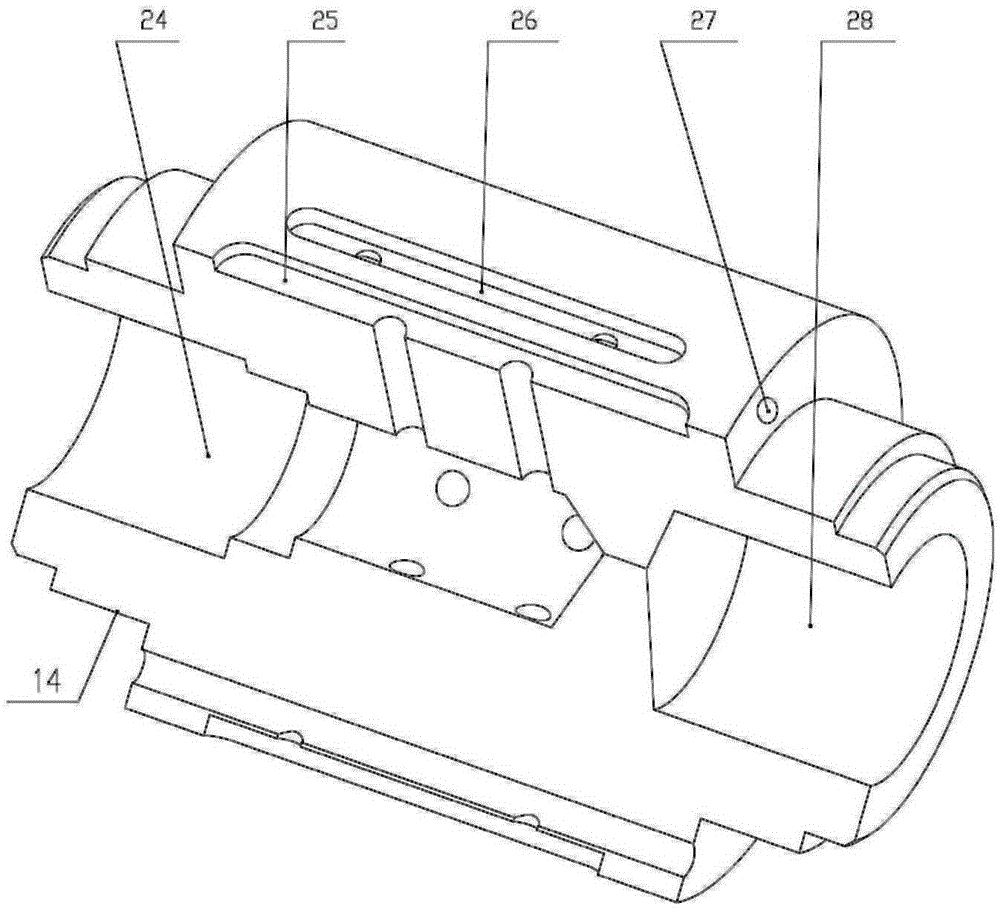

[0034] Such as Figure 1~5 As shown, an embodiment of the lubricating oil circuit system of the planetary gear reducer of the aircraft of the present invention is based on the improvement of the structure of the components in the existing planetary gear reducer, so that it adds an oil passage structure with lubrication function. Including sliding bearing lubricating oil circuit, gear lubricating oil circuit, inner gear lubricating oil circuit and oil collecting groove 5 fixed on the aircraft casing A7. The sliding bearing lubricating oil circuit includes a stepped hole arranged at one end of the planetary wheel shaft 14 for oil intake 24. A plurality of oil inlet grooves 25 evenly distributed on the outer circumference of the planetary wheel shaft 14 and communicated with the stepped hole 24, a plurality of oil outlet grooves 26 evenly distributed on the outer circumference of the planetary wheel s...

Embodiment 2

[0042] Embodiment 2: Planetary gear reducer using the above-mentioned planetary gear reducer lubricating oil circuit system

[0043] Such as figure 1 with figure 2 As shown, a planetary gear reducer of the present invention adopts a transmission mode of input from the sun gear 18 and output from the ring gear 12. The input shaft 17 and the sun gear 18 are connected by splines, and the power is transmitted from the input shaft 17 to The sun gear 18 and the planet gear 16 are mounted on the planet wheel shaft 14 of the planet carrier 22. The planet wheel shaft 14 is provided with a five-oil wedge sliding bearing 2. The two ends of the planet wheel shaft 14 are respectively positioned by the left baffle 3 and the right baffle 13, and The fixing of the planet carrier 22 in the vertical direction is completed by the support structure 21. The support structure 21 is fixed to the aircraft receiver B8 by bolts B10. The middle of the support structure 21 is provided with an oil baffle 20;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com