One-way valve device for waste plastic oil refining equipment

A one-way valve and waste plastic technology, applied in valve devices, mechanical equipment, control valves, etc., can solve problems such as hidden dangers, high energy consumption, unstable chemical properties, etc., and achieve the effect of eliminating hidden safety hazards and preventing leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

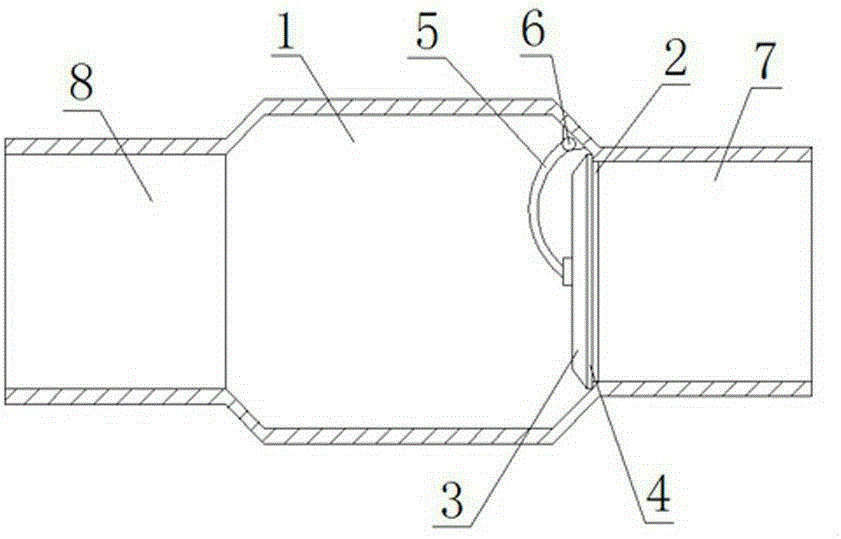

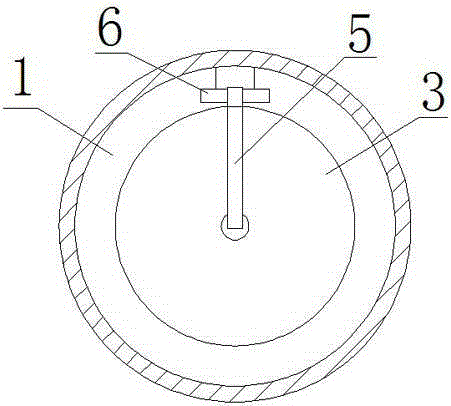

[0013] Referring to the accompanying drawings, a check valve device for waste plastic refining equipment includes a valve cavity 1, a valve seat 2, a valve disc 3, a gasket 4, a rocker 5, a pin shaft 6, a feed pipe 7 and a discharge pipe 8 ;Valve chamber 1 is a hollow structure, with feed pipe 7 and discharge pipe 8 welded at both ends; pin shaft 6 is arranged on the upper part of valve chamber 1, and pin shaft 6 is connected to one end of rocker 5, and the other end of rocker 5 is connected to valve disc 3. A gasket 4 is provided on the disc 3; a valve seat 2 is provided on the contact surface between the feed pipe 7 and the valve chamber 1, and the valve seat 2 is in contact with the gasket 4.

[0014] The valve flap 3 is disc-shaped and can rotate around the pin shaft 6 together with the rocker 5 .

[0015] The size of the valve disc 3 is larger than that of the valve seat 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com