Outer sealing groove structure of O-shaped ring of non-standard sealing face

A technology of sealing groove and sealing surface, applied in flange connection, pipe/pipe joint/pipe fitting, passing element, etc., to reduce offset and slip, solve the problem of O-ring movement, and prolong service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

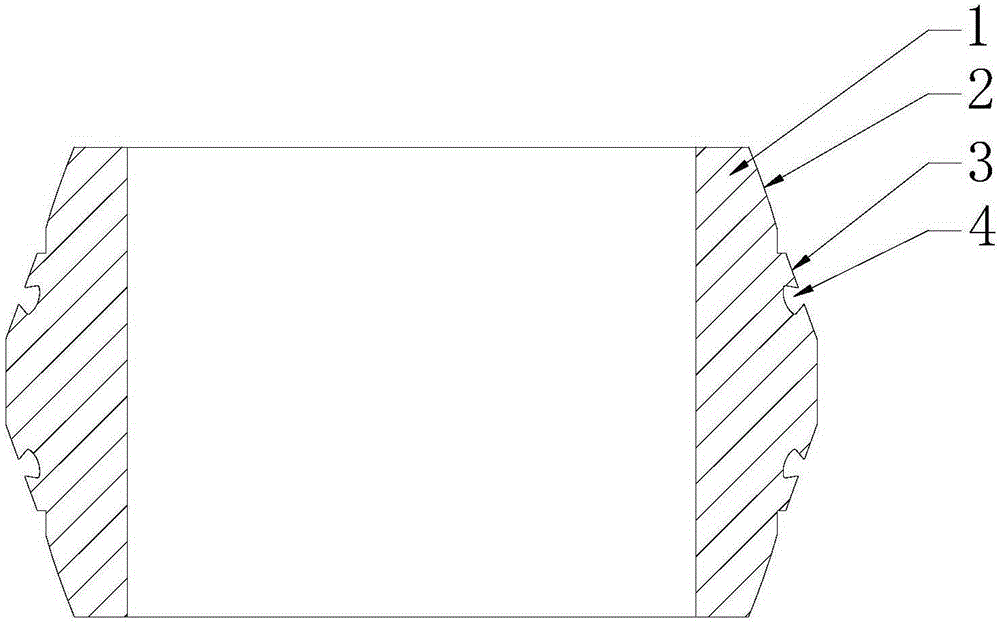

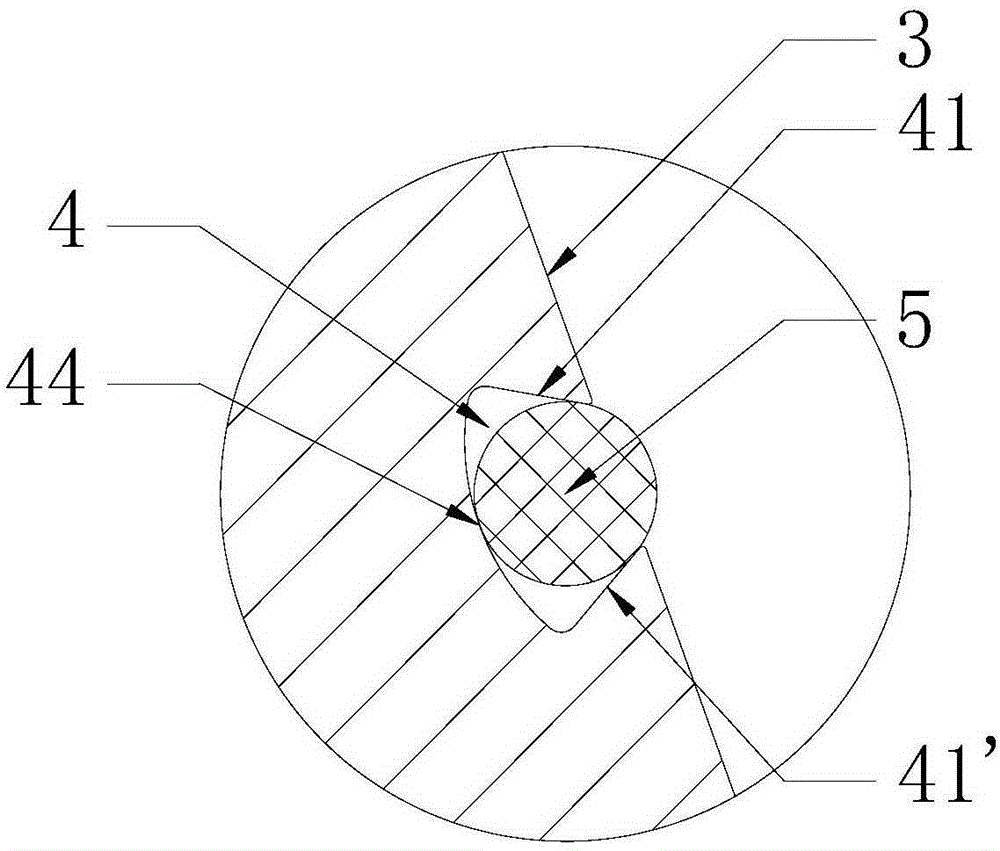

[0018] like figure 1 As shown, the present invention includes: a composite sealing ring 1 installed on the pipeline flange, a spherical sealing surface 2 arranged on the composite sealing ring 1, wherein the spherical sealing surface 2 is provided with a sealing slope 3, and the inside of the sealing slope 3 A non-standard sealing groove 4 is provided, and a second O-shaped sealing ring 5 is housed in the non-standard sealing groove 4 (such as image 3 shown).

[0019] The above-mentioned sealing slope 3 is a non-standard sealing surface.

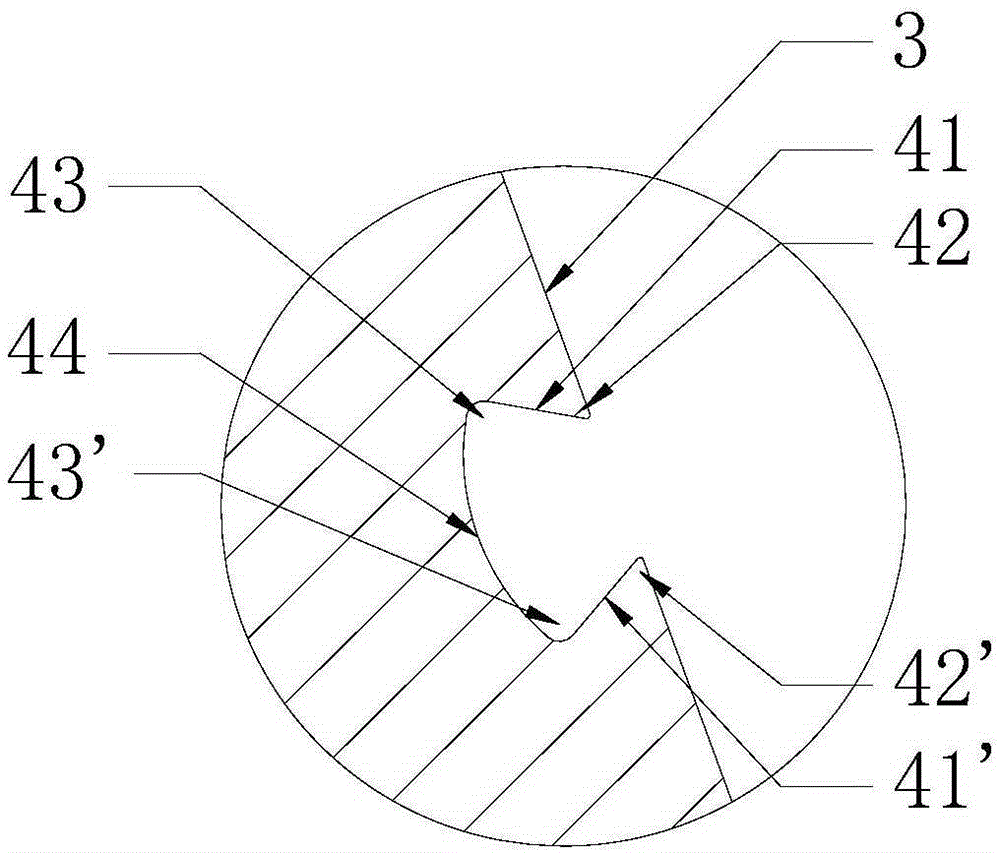

[0020] like figure 2 As shown, the inner cavity of the non-standard seal groove 4 is composed of the opposite non-standard seal groove side walls 41 and 41', and the non-standard seal groove notch rounded corners respectively arranged on the top of the non-standard seal groove side walls 41 and 41'. 42 and 42', the rounded corners 43 and 43' at the bottom of the non-standard sealing groove and the bottom 44 of the non-standard sealing g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com