Pipe connection structure and manifold

A connection structure and water separator technology, applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., can solve problems such as leakage and limited sealing effect of sealing rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

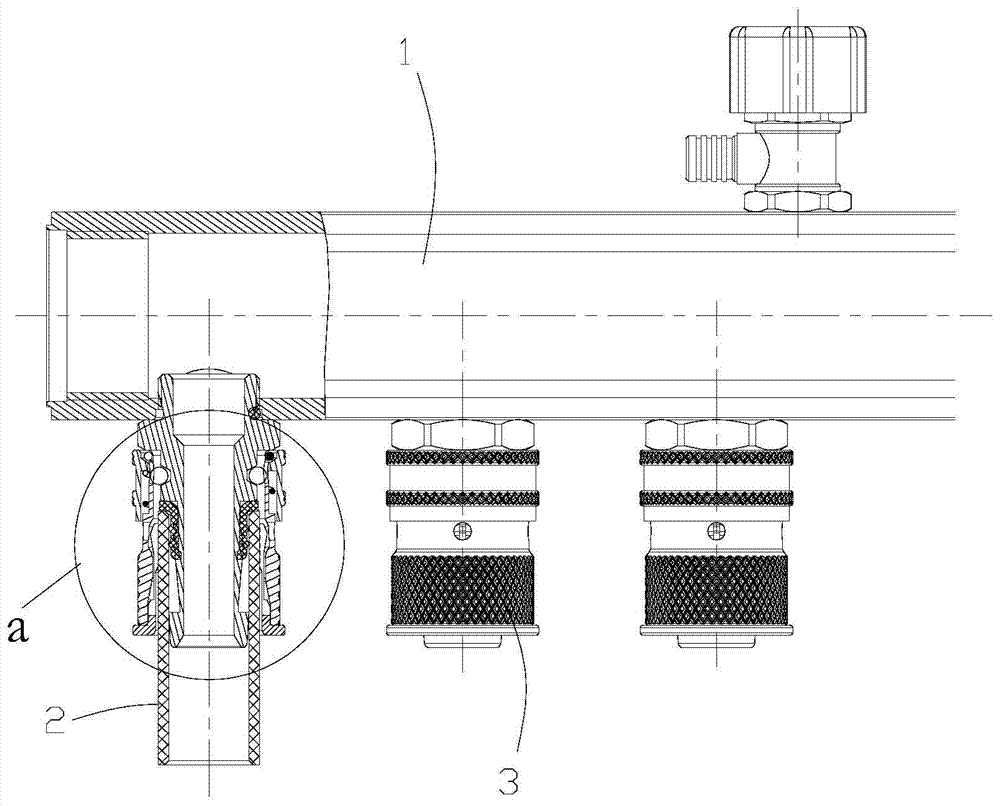

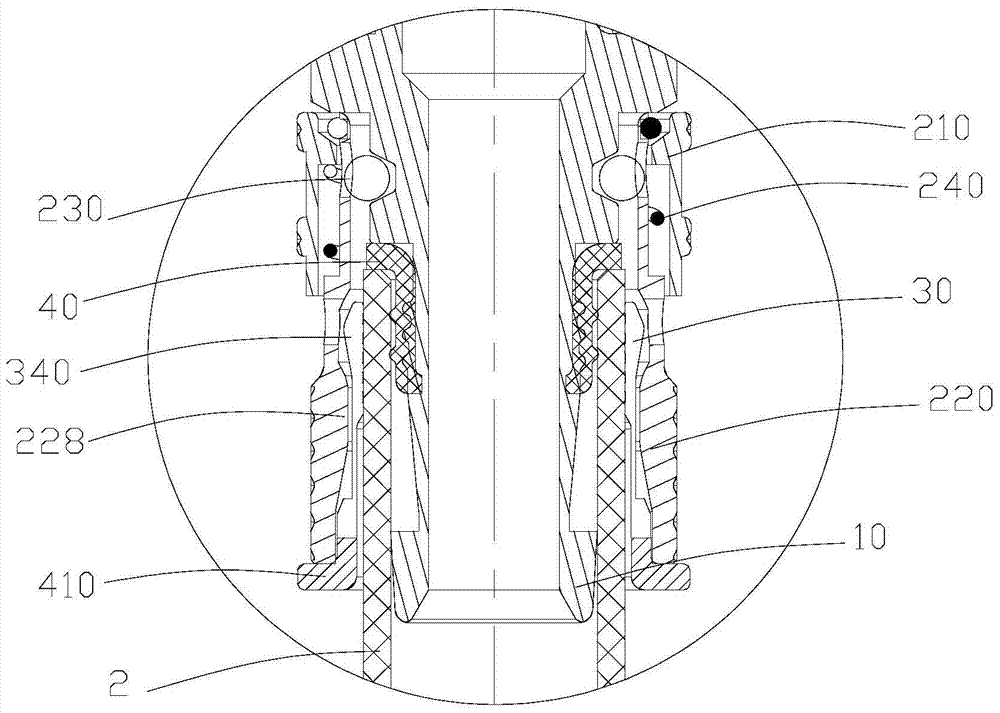

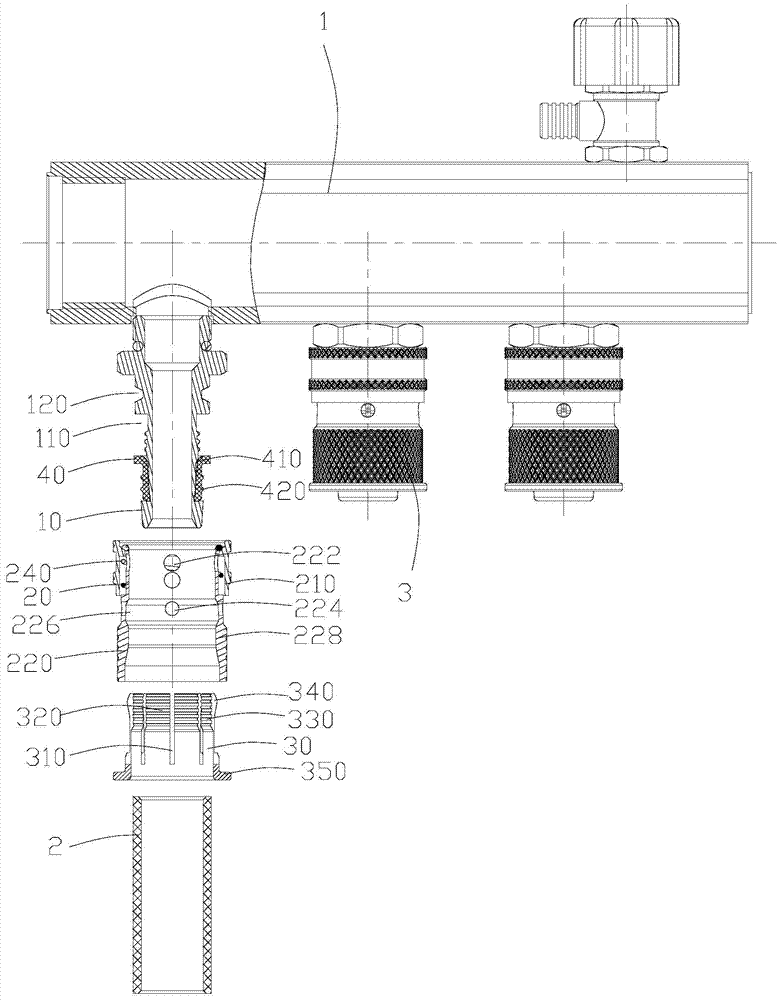

[0026] Such as Figures 1 to 3 As shown, a sub-collector includes a water distributor main pipe 1, a branch pipe 2 and a pipe connection structure 3. The pipe connection structure 3 includes a core body 10, a steel ball circlip mechanism 20, a pipe circlip 30, and a sealing sleeve 40. The outer wall of the core body 10 is provided with an annular groove 110, and the annular groove 110 is arranged at one end close to the outlet of the core body 10, the sealing sleeve 40 is sleeved on the core body 10, and the sealing sleeve 40 is located at In the annular groove 110, the end of the sealing sleeve 40 away from the outlet of the core body 10 is provided with a protrusion 410 protruding in the radial direction thereof, and at least one anti-slip rib 420 is provided on the outer wall of the sealing sleeve 40, and the steel ball retaining spring The mechanism 20 is sleeved on the core body 10 and is detachably connected with the core body 10. The tube retainer 30 is sleeved between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com