Boiler type charcoal-burning steam oven

A boiler and stove grate technology, which is applied in the field of boiler-type charcoal-burning and steaming stoves, can solve the problems of energy waste of ordinary stoves, and achieve the effects of low manufacturing costs, broad market prospects, and simple production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

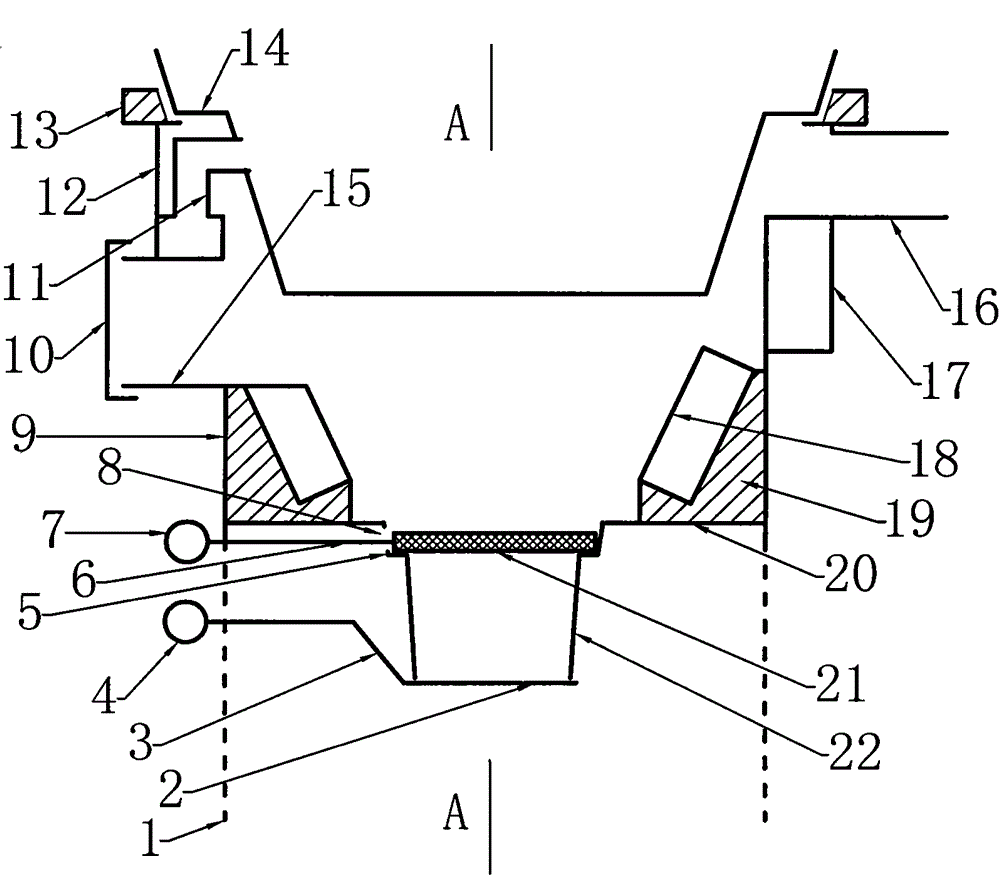

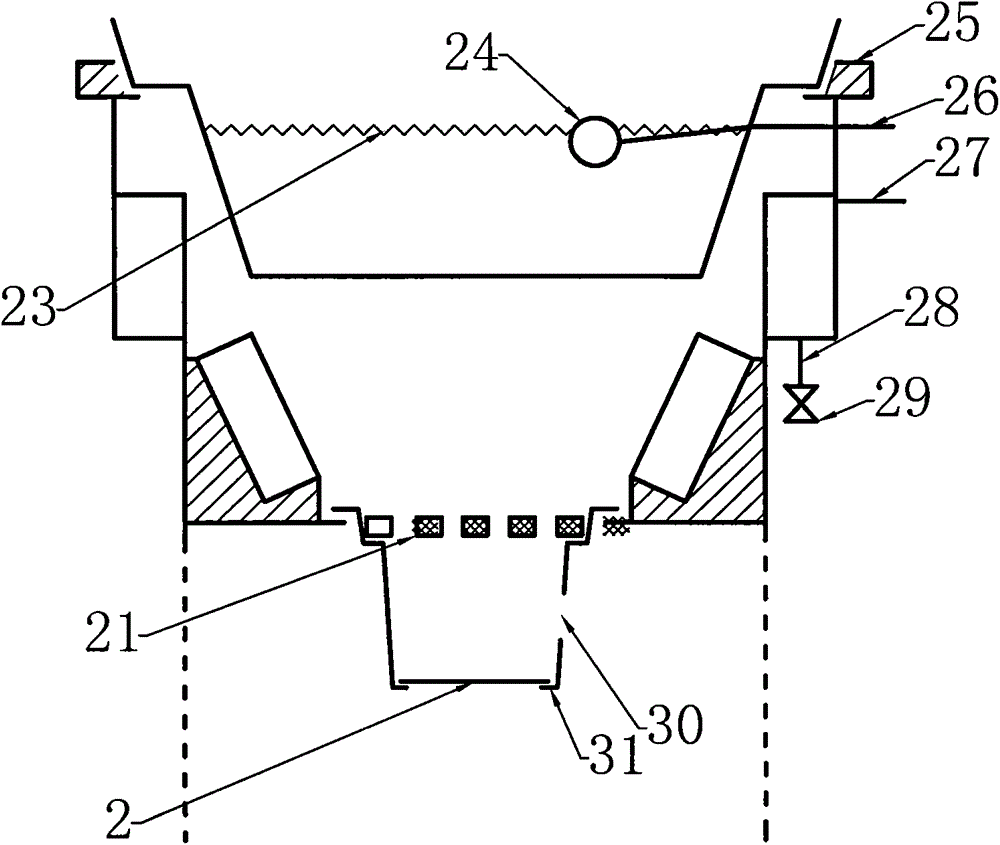

[0020] figure 1 , figure 2 A structural form of a boiler-type charcoal-fired steam stove is jointly described. A boiler-type charcoal-burning steam stove mainly consists of a bracket, a waste heat recovery device, a refractory layer, and an ash hopper. The main body 17 of the waste heat recovery device is a hollow metal body whose shape is cylindrical, or truncated, or prismatic, or truncated; the main body 17 of the waste heat recovery device has a lower annular wing 9 downward; the lower annular wing 9 is A cylindrical, or truncated circular, or prismatic, or truncated circular metal body; the main body 17 of the waste heat recovery device has an upper annular wing 12; the upper annular wing is a cylindrical, or circular A platform-shaped, prism-shaped, or prism-shaped annular metal body; the upper annular wing 12, the smoke pipe 16, the main body of the waste heat recovery device 17, the door opening 15, and the lower annular wing 9 jointly constitute the waste heat reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com