Inner cylinder, shell and vertical oil separator of vertical oil separator

An oil separator and inner cylinder technology, used in refrigeration components, refrigerators, lighting and heating equipment, etc., can solve the problems of cracking, entrainment and backmixing, long time consumption, etc., to enhance stability, reduce the probability of backmixing, Good oil separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

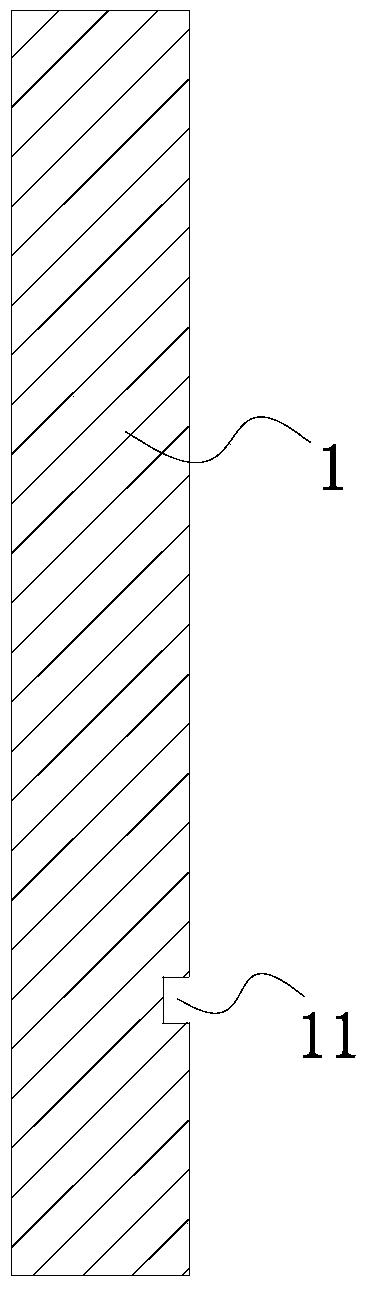

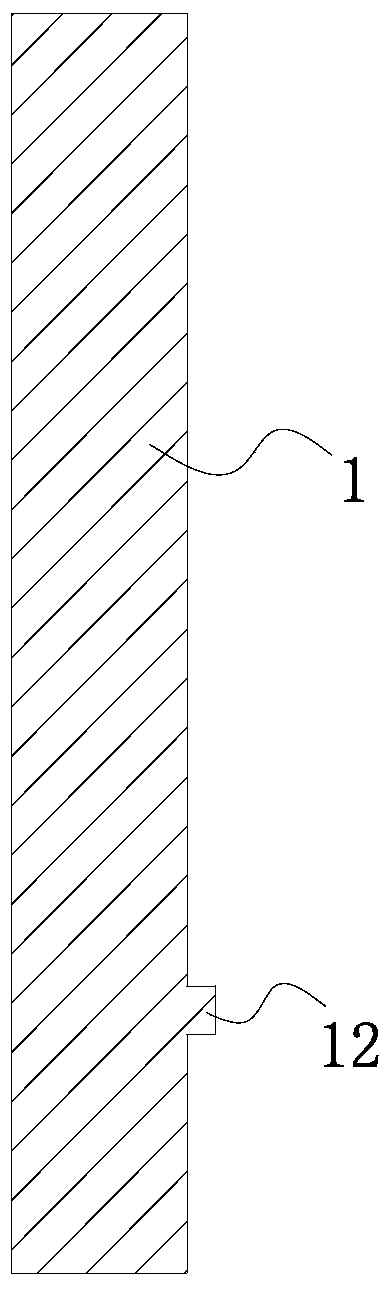

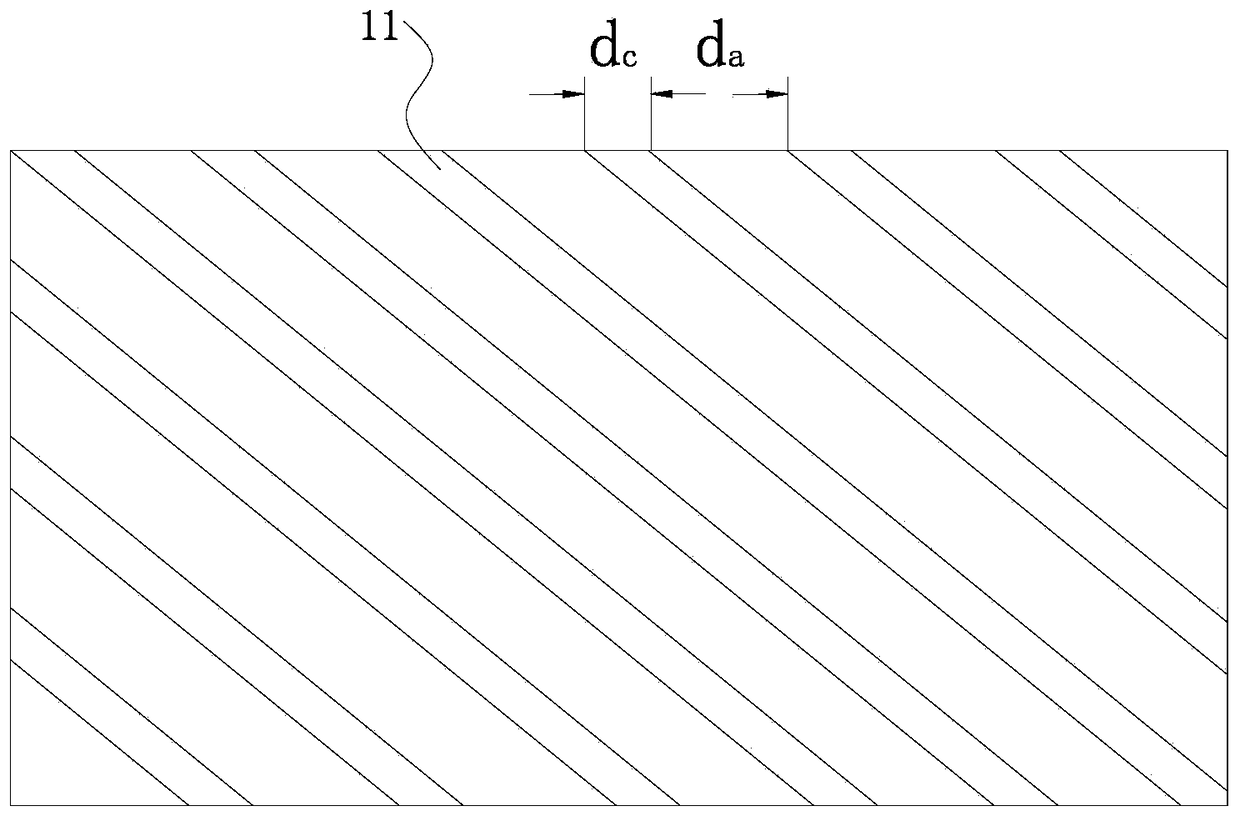

[0030] This preferred embodiment discloses an inner cylinder of a vertical oil separator. The inner cylinder is rolled from the wall plate 1, such as figure 1 and figure 2 As shown, oil guide grooves 11 or oil guide ribs 12 are provided on the inner and outer sides of the wall plate 1 of the inner cylinder; the oil guide grooves 11 and / or oil guide ribs 12 are at least partially along the The outer side of the wall plate 1 is inclined downward.

[0031] The oil guide groove 11 has adsorption function, which can improve the ability of the oil film to resist fluid erosion, reduce the possibility of the fluid impacting the oil film on the wall surface, and then take away the oil droplets, increase the speed of the oil film flowing down the wall surface, and improve the oil return capacity of the oil separator . The oil guide ribs 12 are sandwiched with the side of the wall plate 1 to form a concave angle structure, and the two oil guide ribs 12 are sandwiched with the side of...

Embodiment 2

[0039] This preferred embodiment discloses a casing of a vertical oil separator. The housing is rolled from wall plates, and oil guide grooves and / or oil guide ribs are provided on the inner side of the wall plates of the housing; the oil guide grooves and / or oil guide ribs are at least partially Slope down the inside side of the siding. An oil guide plate is arranged at the end of the oil guide groove and / or the oil guide rib.

[0040] The shape and size of the oil guide groove and the oil guide rib are the same as those in the first preferred embodiment.

Embodiment 3

[0042] This preferred embodiment discloses a vertical oil separator. Such as Figure 7 As shown, the vertical oil separator may only include the inner cylinder 2 as described in the first preferred embodiment, may only include the housing 3 as described in the second preferred embodiment, and may also include the same as described in the first preferred embodiment The inner cylinder 2 and the housing 3 as described in the second preferred embodiment, the inner cylinder 2 is arranged in the housing 3 .

[0043] Regardless of the number of oil-guiding grooves 11 and oil-guiding ribs 12 on the wall plate 1 is large or small, the number of oil-guiding plates arranged at the ends of the oil-guiding grooves 11 and / or oil-guiding ribs 12 should not be less than four, Otherwise, it will not be able to prevent the oil droplets from falling directly. At the same time, in order to avoid excessively increasing the pressure drop, the number of oil guide plates should not exceed ten.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com