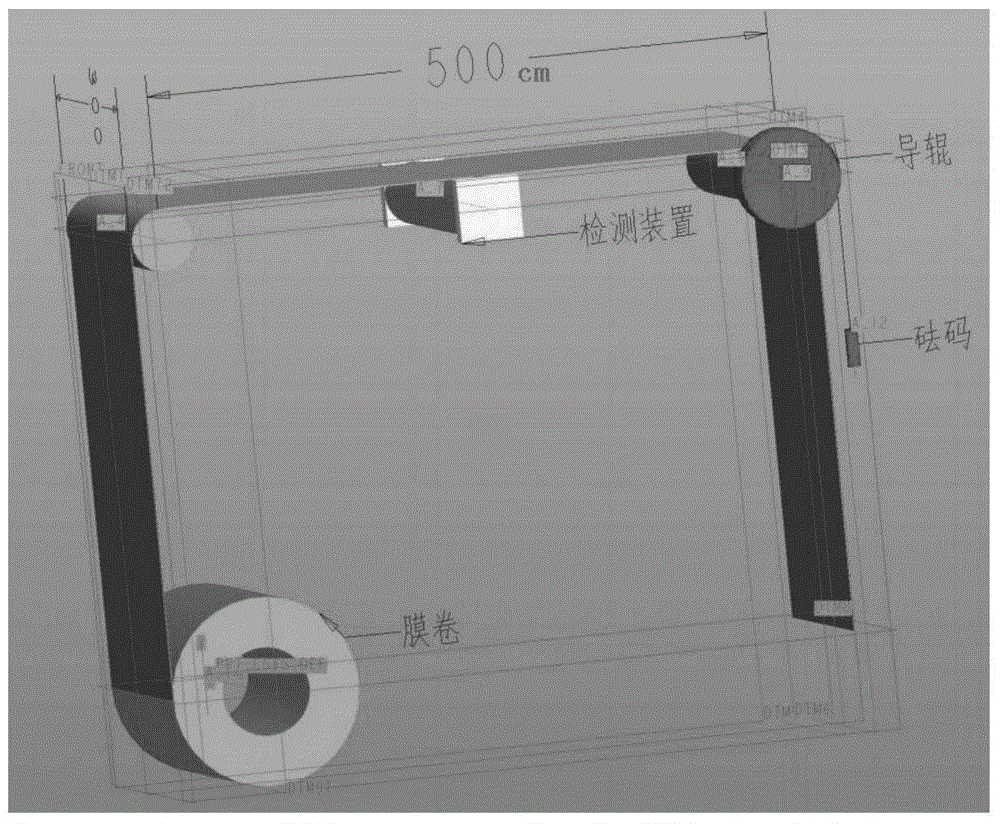

Lithium battery diaphragm surface flatness detection apparatus and method

A technology for surface flatness and lithium battery diaphragm, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of no objective test method, unable to form judging standards, and affect the smoothness of the appearance of the diaphragm, so as to achieve simple detection device, The effect of high efficiency and simple detection operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

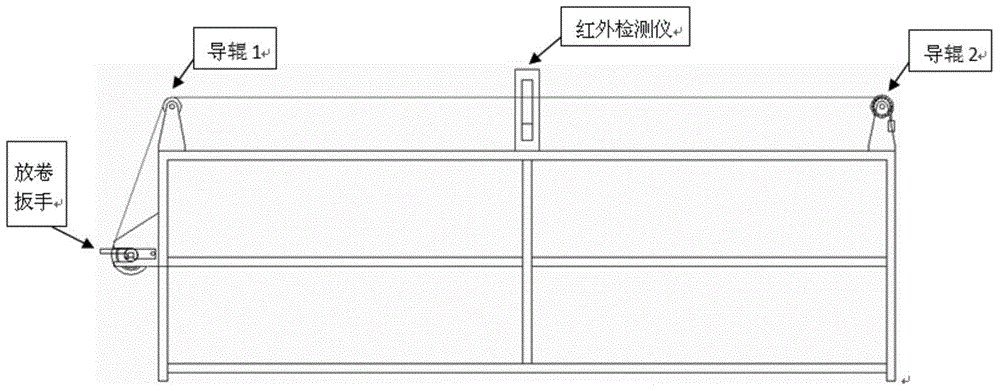

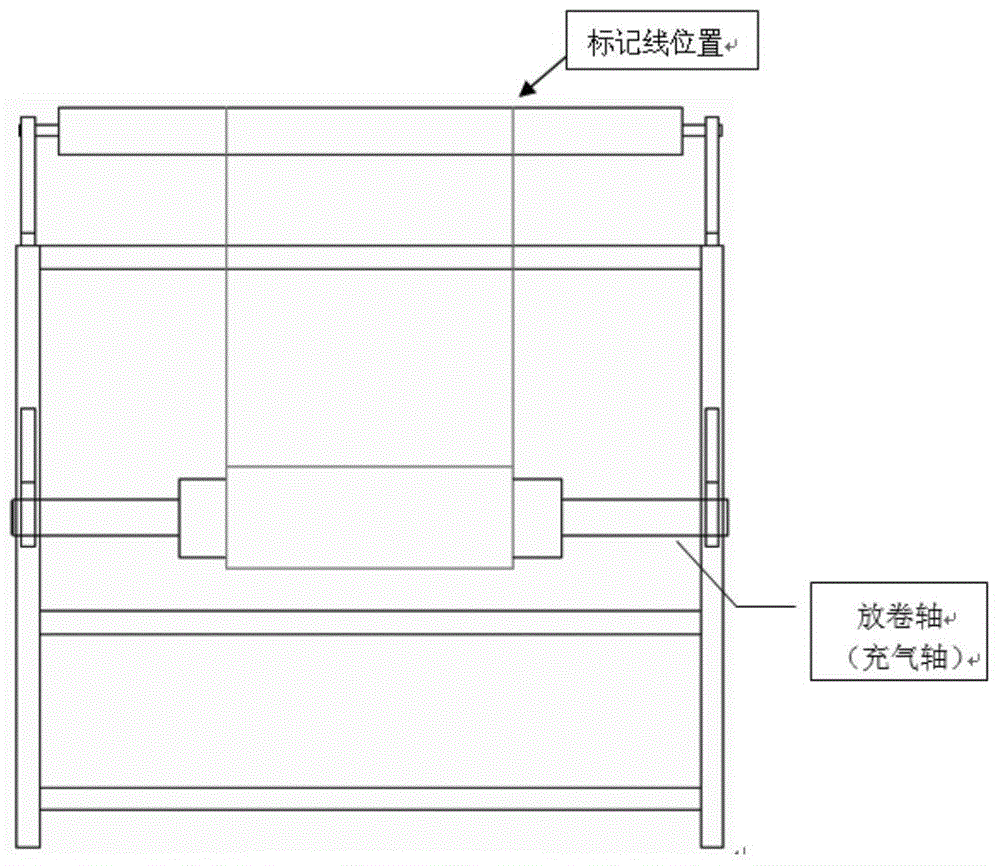

[0030] a. Put the diaphragm on the unwinding shaft, pull one side of the diaphragm and pass it from the guide roller 1 to the guide roller 2, and move the diaphragm core so that the edge of the diaphragm overlaps with the marking line on the guide roller 1

[0031] b. Inflate the unwinding air shaft to fix the diaphragm, put down the wrench, and fix the bearing of the air shaft

[0032] c. Apply a layer of glue on the guide roller 2, flatten the diaphragm, make the edge of the diaphragm overlap with the marking line on the guide roller 2, and paste the diaphragm on the guide roller 2

[0033] d. Select a weight, hang it on the weight groove on the guide roller 2, wait for 5 seconds, and record the value after the value on the reader is stable

[0034] e. Remove the weight, deflate the inflatable shaft, and remove the diaphragm

[0035] In step a, the shaft sleeve of the corresponding size can be matched according to the size of the winding core on the reel.

[0036] In steps...

Embodiment 2

[0042] Select 3 rolls of 16u*621mm*1000m diaphragm, and carry out the surface roughness test according to the above technical scheme, in which the weight of the weight is 10N, and the results are as follows:

[0043] Table 1 The detection values corresponding to different diaphragm samples

[0044] sample number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com