Liquid level alarm device for corrosive solution

A liquid level alarm and corrosive technology, applied in the direction of float level indicator, etc., can solve the problems of easy sticking of floats and high liquid level cost, and achieve the effect of solving easy sticking and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

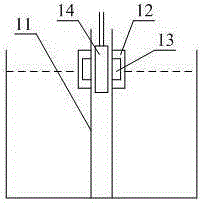

[0020] An embodiment of the present invention provides a liquid level alarm device for corrosive solutions, the liquid level alarm device for corrosive solutions includes an inductive feedback oscillating circuit, a circuit board with holes, and a float with an iron core and the alarm circuit, figure 2 It is a partial structural schematic diagram of monitoring the liquid level by using the liquid level alarm device for corrosive solution in this embodiment.

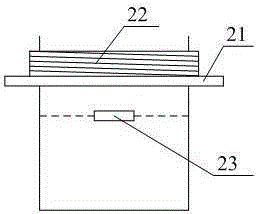

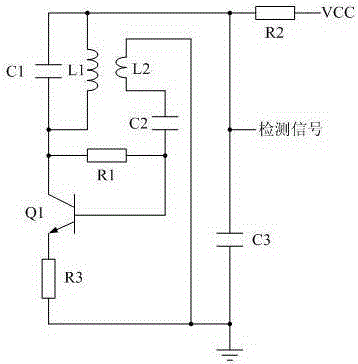

[0021] Specifically, the inductive feedback oscillation circuit includes two parts: the inductor 22 and other devices except the inductor 22 . The inductance 22 includes a main vibration coil, a feedback coil and a shaft frame, the main vibration coil and the feedback coil are wound on the shaft frame, the shaft frame i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com