A fully automatic gas detection device and its application method

A gas detection, fully automatic technology, applied in color/spectral characteristic measurement, analysis through chemical reaction of materials, instruments, etc., can solve the problem that the absorption liquid cannot react to the instantaneous change of gas concentration, and the surface tension of the film cannot be controlled Damage, poor system adaptability and other problems, to achieve the effect of simple structure, short response time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

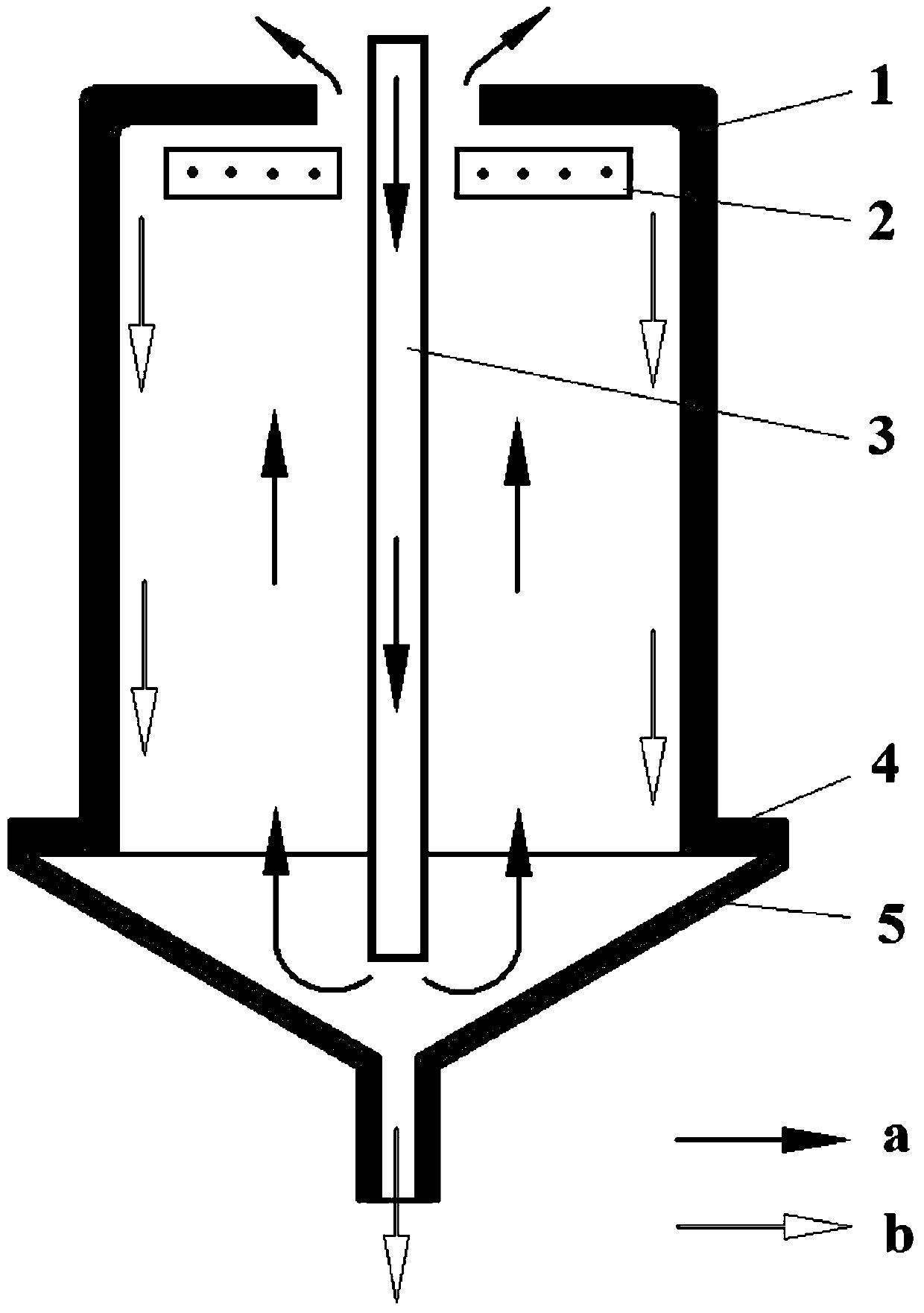

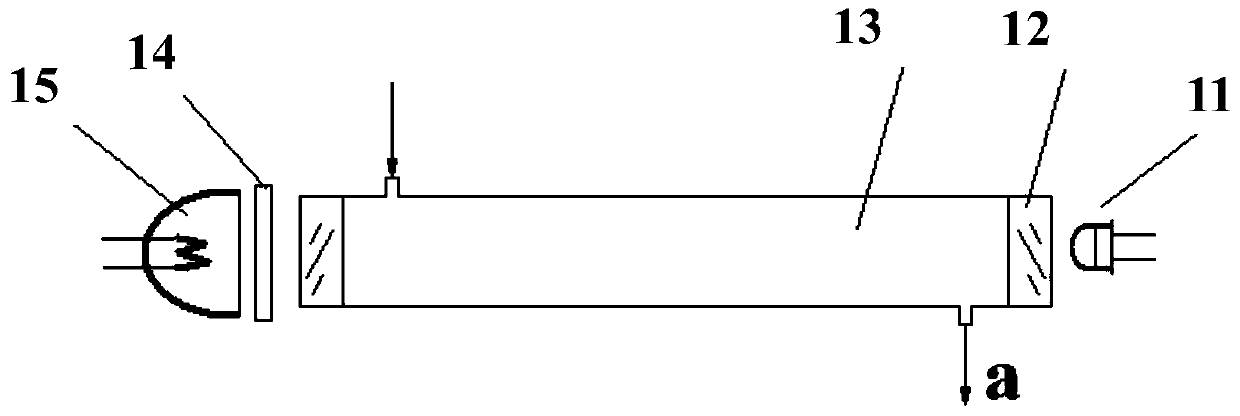

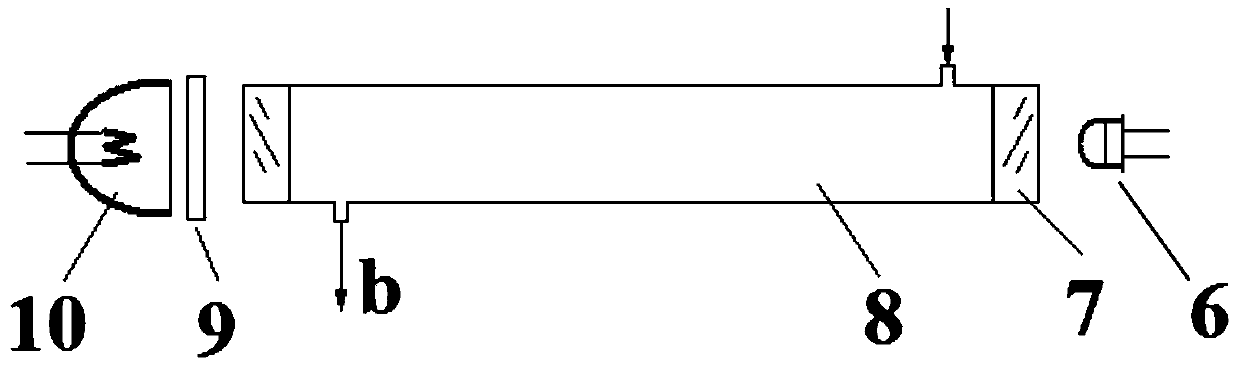

[0024] A fully automatic gas detection device, the device includes a falling film gas absorption tube and a colorimetric cell, the colorimetric cell is composed of two optical comparison systems of a detection cell and a reference cell, wherein the flow through the detection cell is The absorption liquid that passes through the falling film gas absorption tube, while the original liquid of the absorption liquid flows through the reference cell. The difference in absorbance between the two cells is directly related to the concentration of the gas being measured. The upper end of the falling film gas absorption tube is provided with a tube wall 1, and the tube wall 1 is provided with a distributor 2 and a gas introduction tube 3; the lower end of the falling film gas absorption tube is provided with a collector 5; The upper end and the lower end of the falling film gas absorption tube are sealed and connected; the sealed connection is through a sealing device 4; the sealing devi...

Embodiment 2

[0031] A kind of application method of described automatic gas detection device, described method comprises the following steps:

[0032] ① The gas to be measured is introduced from the top of the gas introduction pipe 3 of the falling film gas absorption tube, flows downward along the gas introduction pipe, and flows out from the bottom of the gas introduction pipe 3, then the gas to be measured turns back up, and then flows from the falling film Outflow from the top opening of the membrane gas absorption tube; figure 1 As shown by the arrow a in

[0033] ② The raw liquid of the absorption liquid is sprayed onto the inner wall of the tube wall 1 by the distributor 2 in the falling film gas absorption tube, flows down the inner wall freely, flows to the collector 5, and flows out from the liquid outlet at the bottom of the collector 5, namely Absorbent; such as figure 1 Shown by arrow b in

[0034] ③The gas to be measured in step ① and the absorption liquid in step ② flow i...

Embodiment 3

[0044] ①A. Taking 20ppm ammonia / air detection as an example, the absorbing liquid stock solution is 0.1M phenolphthalein indicator aqueous solution, containing 0.01% wt of nonylphenol polyoxyethylene ether, the first filter 14 and the second filter 9 are both 550nm.

[0045] B. The structure of the falling film gas absorption tube: a distributor 2 is arranged in the upper end of the quartz glass tube (that is, the tube wall 1) with a length of 120 mm and a diameter of 12 mm. The distributor 2 has an outer diameter of 10 mm, an inner diameter of 5 mm and a height of 5 mm polytetrafluoroethylene The outer wall of the vinyl ring has 12 small holes with a diameter of 2.0mm. The liquid is sprayed from the small holes, sprinkled on the wall of the quartz glass tube, and flows down freely. A quartz glass tube with a diameter of 5mm and a length of 15mm and an inner diameter of 3.5mm (that is, the gas inlet tube 3 made of quartz glass) passes through the center of the ring of the dist...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com