Capacitive touch panel having approaching sensing function and scan method thereof

A capacitive touch and proximity sensing technology, applied in electrical digital data processing, data processing input/output process, instruments, etc., can solve the problems of increasing difficulty in manufacturing induction coils, increasing manufacturing costs, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The technical means adopted by the present invention to achieve the intended purpose are further described below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

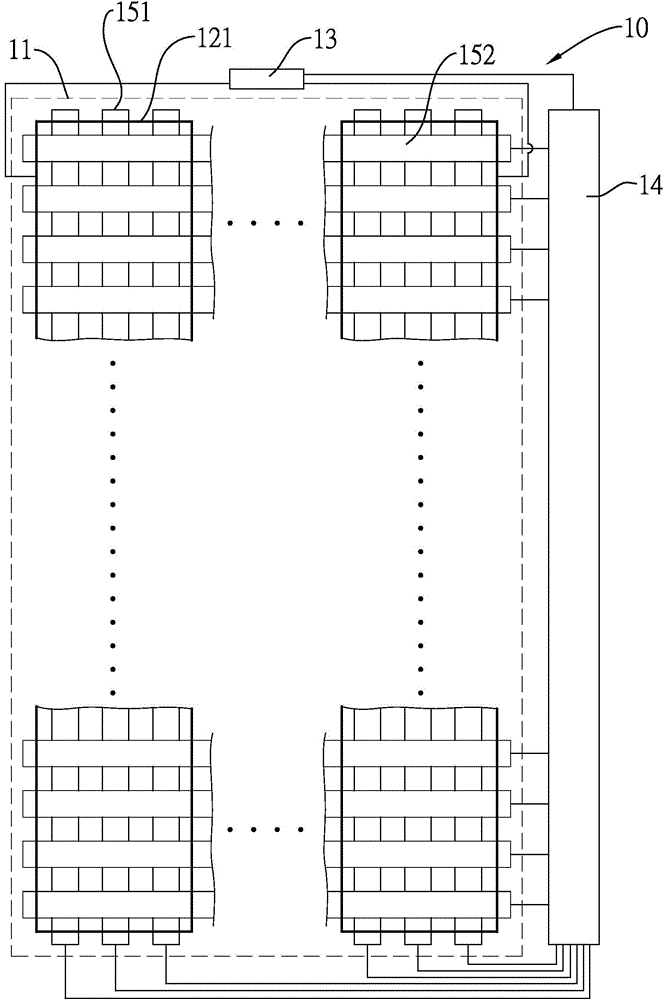

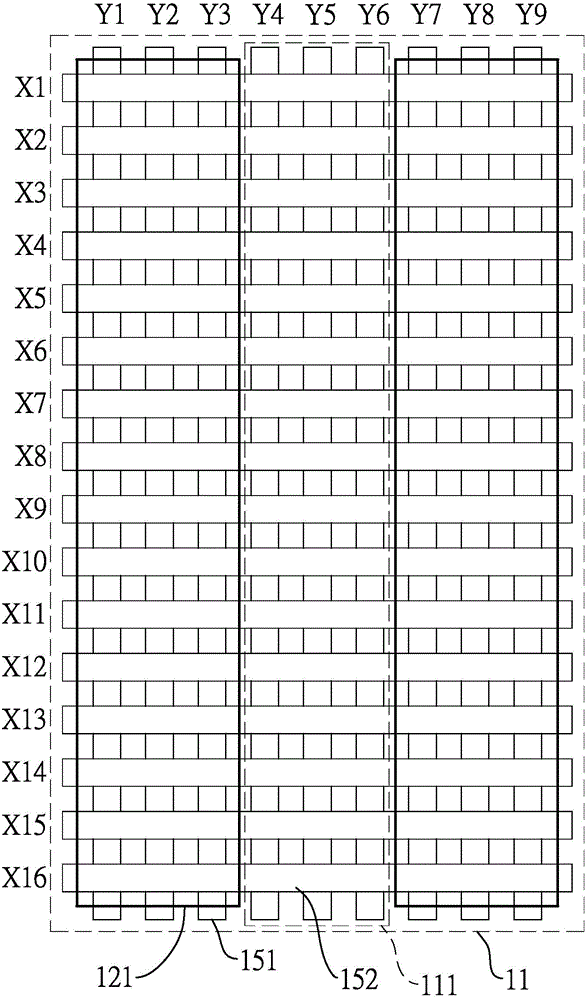

[0087] see figure 1 and figure 2 As shown, the capacitive touch panel 10 with proximity sensing function of the present invention includes a touch operation area 11 , a plurality of induction coils 121 , a coil controller 13 and a touch panel controller 14 .

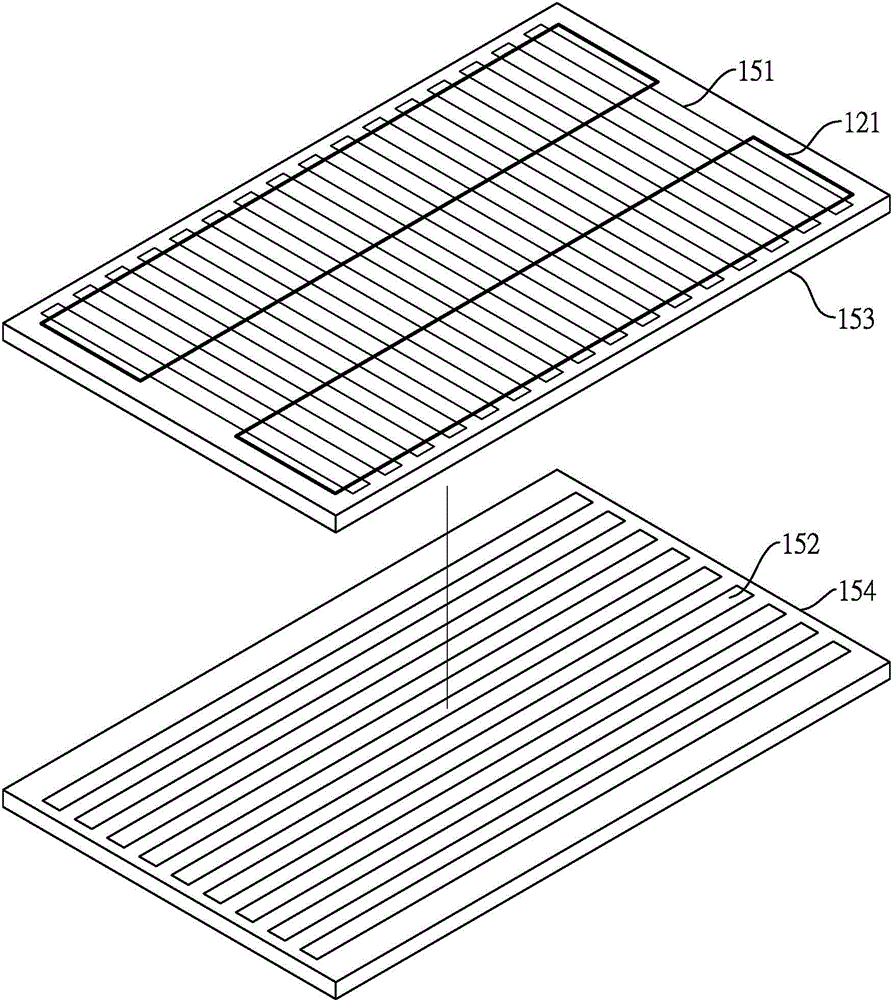

[0088] The plurality of induction coils 121 are arranged at intervals in the touch operation area 11, and are electrically connected to the coil controller 13, and the coil controller 13 respectively outputs a driving signal to each induction coil 121, so that each induction coil 121 generates an electromagnetic field, and each induction coil 121 generates a third-axis induction signal corresponding to its own electromagnetic field change. The coil controller 13 receives the third-axis induction signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com