Wooden door paint spraying clamping device

A technology of clamping device and wooden door, which is applied in the field of devices supporting workpieces, can solve the problems of long time consumption and low work efficiency, and achieve the effect of short time consumption, ensuring stability and good self-locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

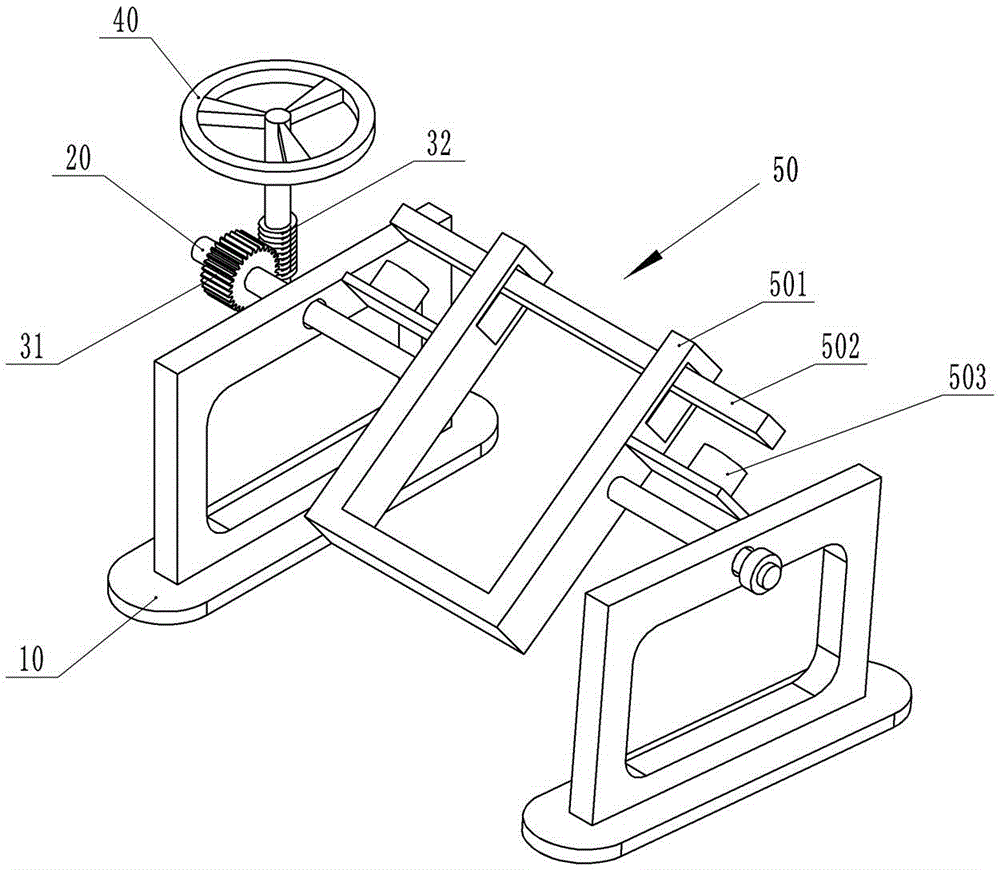

[0022] like figure 1 As shown, the wooden door spraying clamping device includes a frame 10, a rotating rod 20, a worm wheel 31, a worm 32, a rotating handle and a clamping unit for clamping a wooden board. The clamping unit is rotatably installed on the frame 10 through the rotating rod 20 , and the worm wheel 31 and the rotating rod 20 are coaxially welded and fixed together. The worm screw 32 is engaged with the worm wheel 31, and the turning handle is welded on the worm screw 32. The clamping unit includes a clamping frame 501 , a clamping rod 502 and an electromagnet 503 . The clamping frame 501 is U-shaped, and the two side walls of the clamping frame 501 are processed with slide grooves, and the clamping rod 502 can slide up and down in the slide grooves. The clamping rod 502 is made of iron, and the outer wall of the clamping rod 502 is coated with antirust paint. When the electromagnet 503 is energized, the electromagnet 503 and the clamping rod 502 attract magneti...

Embodiment 2

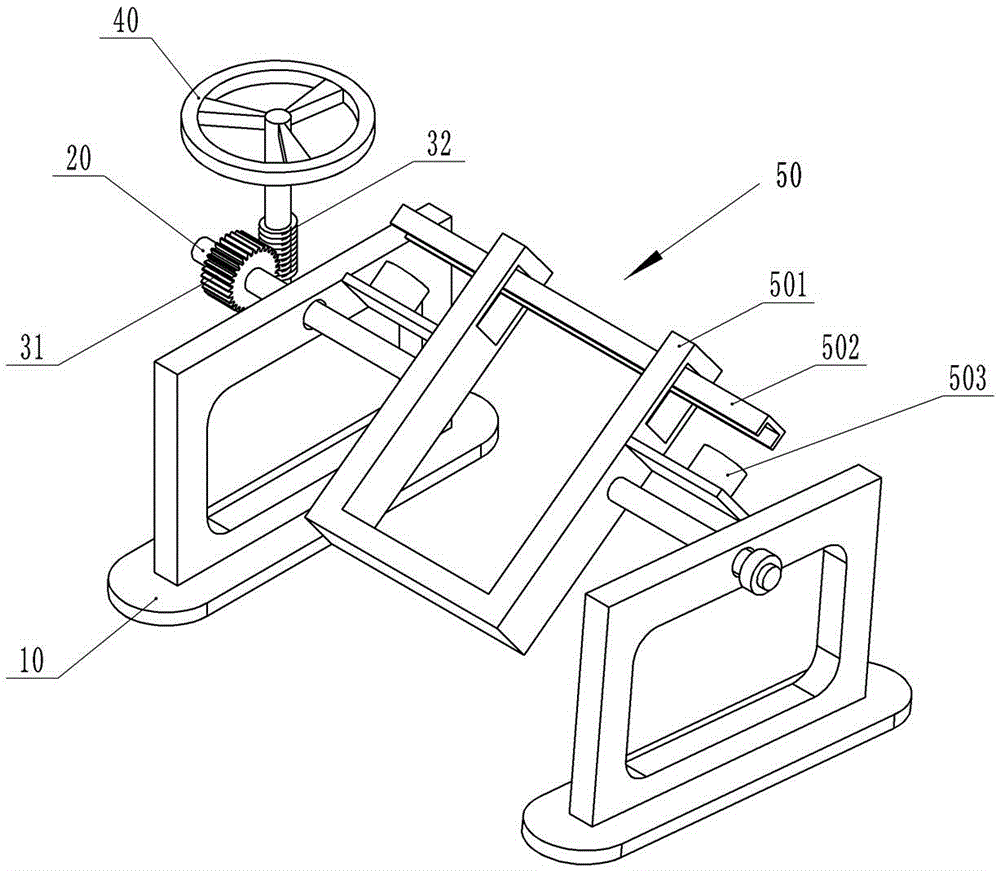

[0025] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the clamping rod 502 is provided with a groove for accommodating part of the wood board. The planks can be snapped into the grooves for better clamping. Moreover, the inner wall of the groove is covered with a layer of rubber layer. When the clamping rod 502 clamps the board, it has a relatively high speed, and the rubber layer has a certain buffering effect to avoid damage to the board due to the fast speed.

Embodiment 3

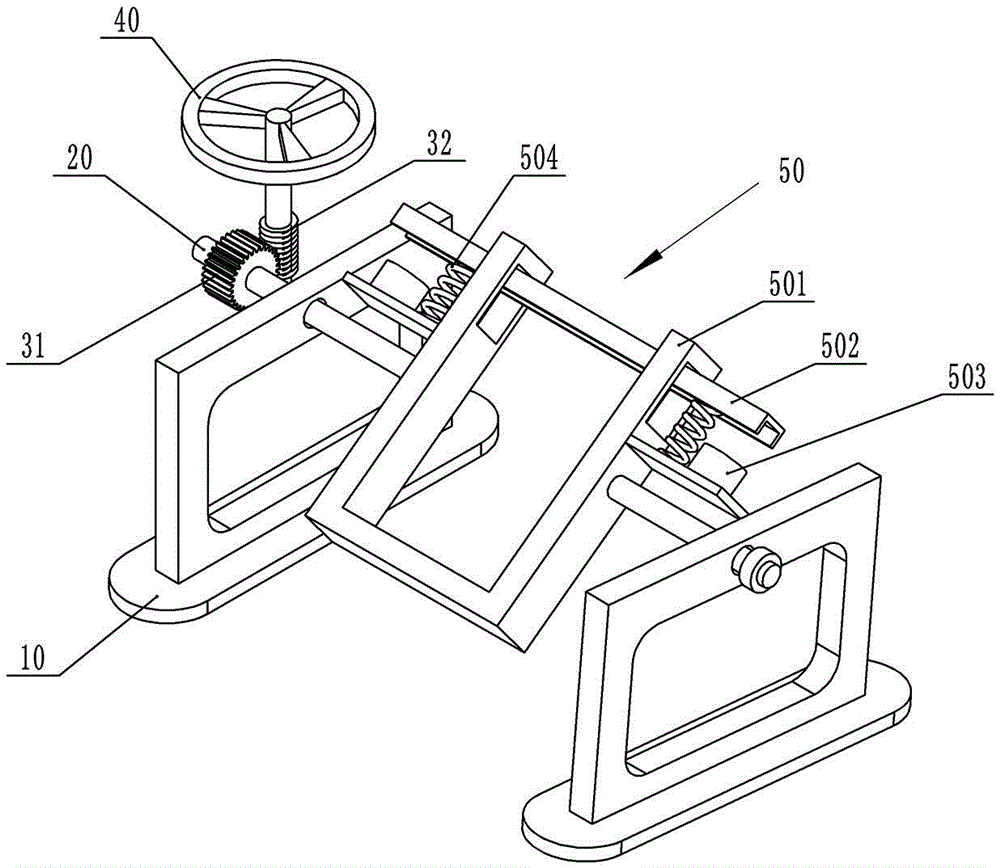

[0027] like image 3 , Figure 4 As shown, the difference between this embodiment and Embodiment 2 is that this solution also includes an elastic member 504 for the reset member of the clamping rod 502 . The elastic member 504 is a stainless steel compression spring, the upper end of the elastic member 504 is fixed on the clamping rod 502 , and the lower end is fixed on the clamping frame 501 . When the electromagnet 503 is energized, the electromagnet 503 and the clamping rod 502 are magnetically attracted to each other, and overcome the elasticity of the elastic member 504 to clamp the plank; when the electromagnet 503 is powered off, the elastic member 504 automatically ejects the clamping rod 502 , without manually removing the clamping rod 502.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com