Automatic paint spraying device for plate processing

A technology for sheet metal processing and sheet metal processing, applied in the field of automatic painting devices for sheet metal processing, can solve the problem of low degree of automation, and achieve the effects of speeding up drying speed, convenient painting and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

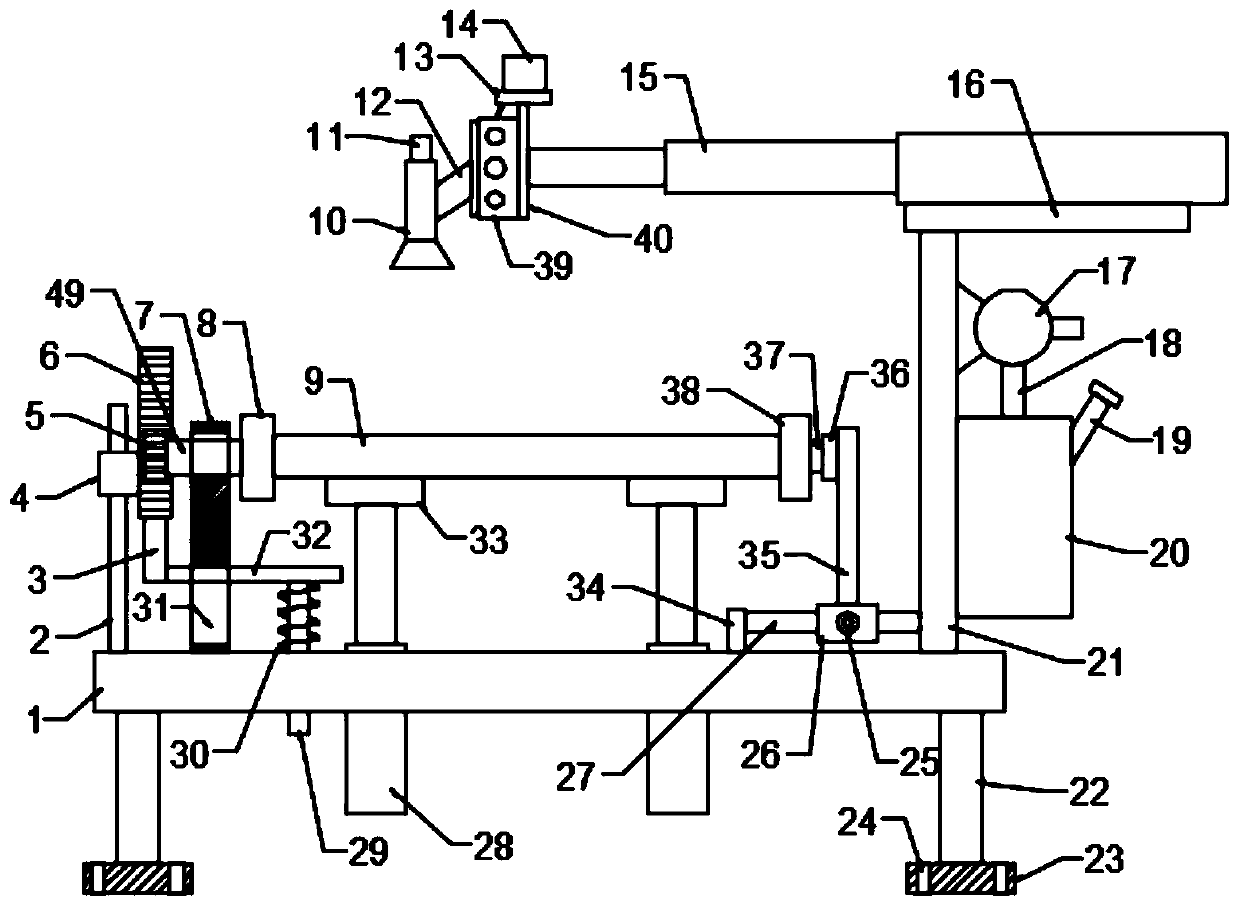

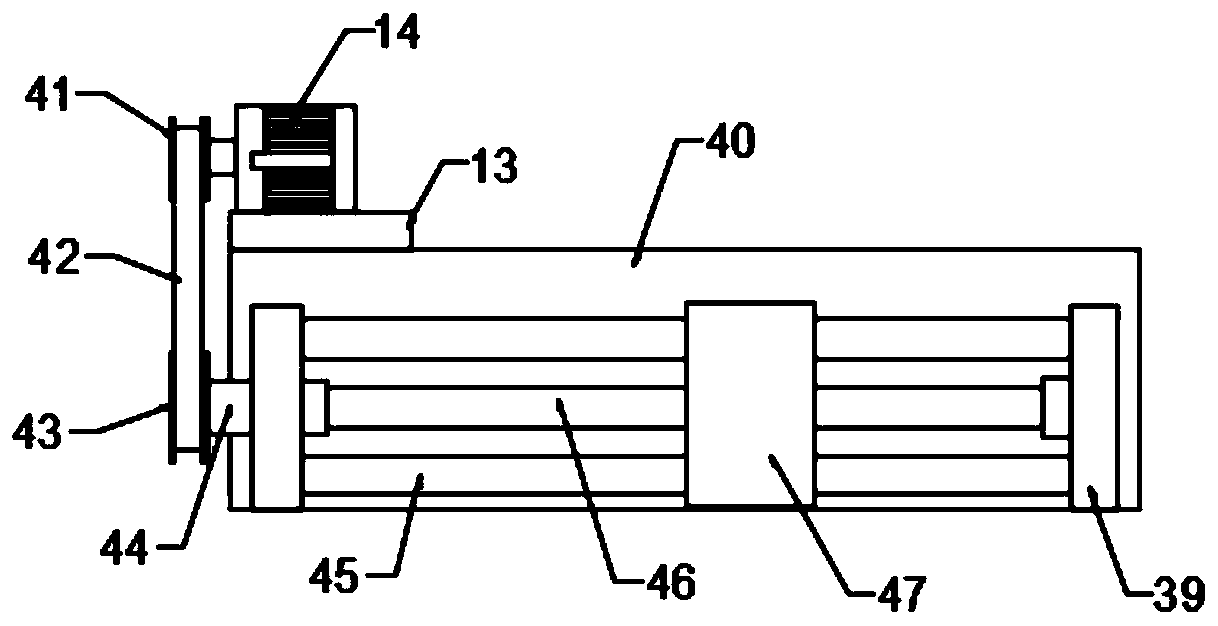

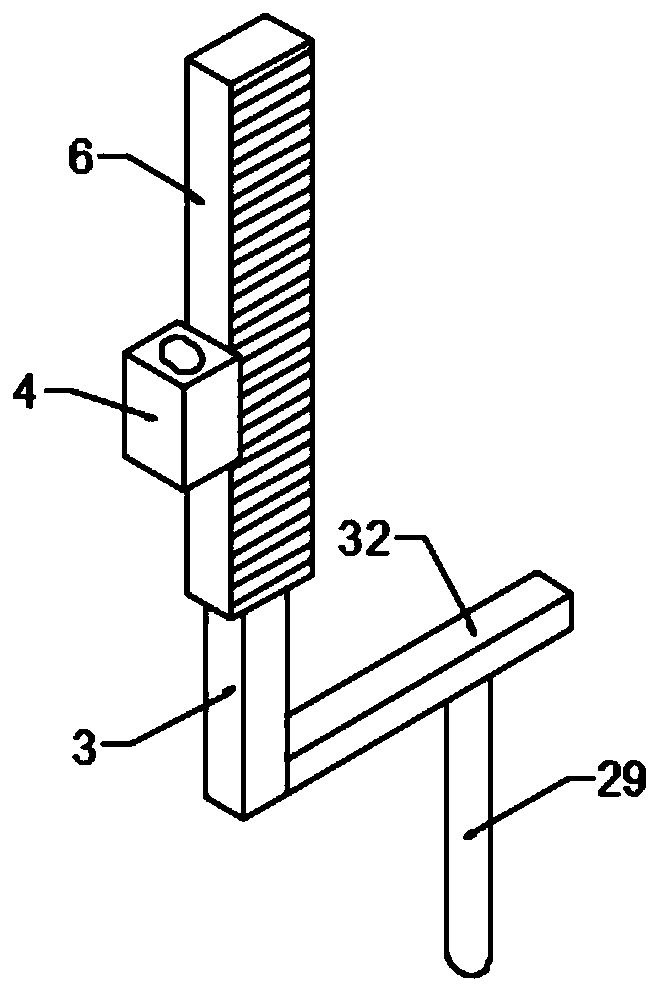

[0028] see Figure 1-3 , in an embodiment of the present invention, an automatic painting device for plate processing, including a workbench 1, a plate 9 and a paint spray head 10, a third vertical plate 21 is fixed on the workbench 1, and a paint bucket is installed on the third vertical plate 21 20, the paint bucket 20 is provided with a filling pipe 19; the second electric telescopic rod 28 and the first vertical plate 7 are installed on the workbench 1, and the telescopic end of the second electric telescopic rod 28 is connected with a support plate 33, the first A bearing on the vertical plate 7 is connected with a first rotating shaft 49, and one end of the first rotating shaft 49 is provided with a first splint 8, and the workbench 1 is also provided with a clamping assembly for clamping the plate 9;

[0029] The top of the third vertical plate 21 is provided with a mount 16, the mount 16 is equipped with a first electric telescopic rod 15, the telescopic end of the fir...

Embodiment 2

[0040] see Figure 4 , in the embodiment of the present invention, an automatic painting device for plate processing is different from embodiment 1 in that a baking lamp 48 is installed on the workbench 1; after one side of the plate 9 is painted, turn it over to the lower side, The baking lamp 48 can dry the paint to speed up the drying speed; after the painting on the other side is completed, the second electric telescopic rod 28 drives the support plate 33 to rise, and the support plate 33 no longer presses the cross bar 32, and is driven by the compressed spring 30 The cross bar 32 moves up, and the rack 6 is used to drive the plate 9 to turn over again, and the other side of the plate 9 can be dried by the oven lamp 48 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com