Motorcycle lower right trailing arm support molding stamping die

A technology for stamping dies and motorcycles, applied in the field of stamping dies, can solve the problems of unguaranteed product quality, increased manufacturing costs, and high manufacturing costs, and achieve the effects of simple structure, improved production efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

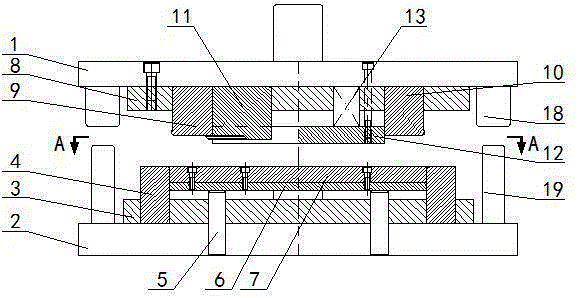

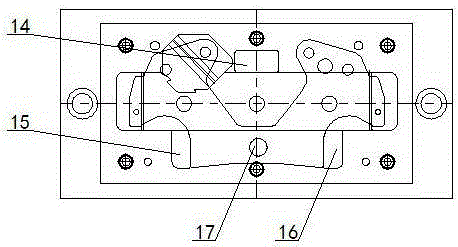

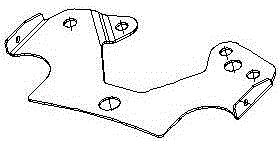

[0013] Embodiment 1: as figure 1 , 3 As shown, a stamping mold for forming the right lower trailing arm support of a motorcycle includes an upper template 1 and a lower template 2, a convex template 3 is arranged on the upper end surface of the lower template 2, and the two ends of the convex template 3 are respectively A forming insert 4 is provided, and a push rod 5 is vertically arranged on the lower template 2, and a backing plate 6 is arranged on the upper end surface of the push rod 5 and between the forming inserts 4, and the backing plate 6 A die pushing core 7 is arranged on the top, a punch fixing plate 8 is arranged on the lower end surface of the upper template 1, and a punch A9 and a punch B10 are symmetrically arranged on the punch fixing plate 8 and along the center line. The inner side of the punch A9 is provided with a punch C11 close to the punch A9, and a stripping plate 12 is arranged below the punch fixing plate 8, and a stripping plate 12 is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com