Method and device for controlling roller seam deviation in soft pressing process or hard pressing process

A control method and reduction control technology, which are applied in the field of continuous casting, can solve problems such as damage to the tension leveler, deterioration of the quality of the billet, inability to improve the internal quality of the billet, etc., and achieve the effect of improving stability and ensuring control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

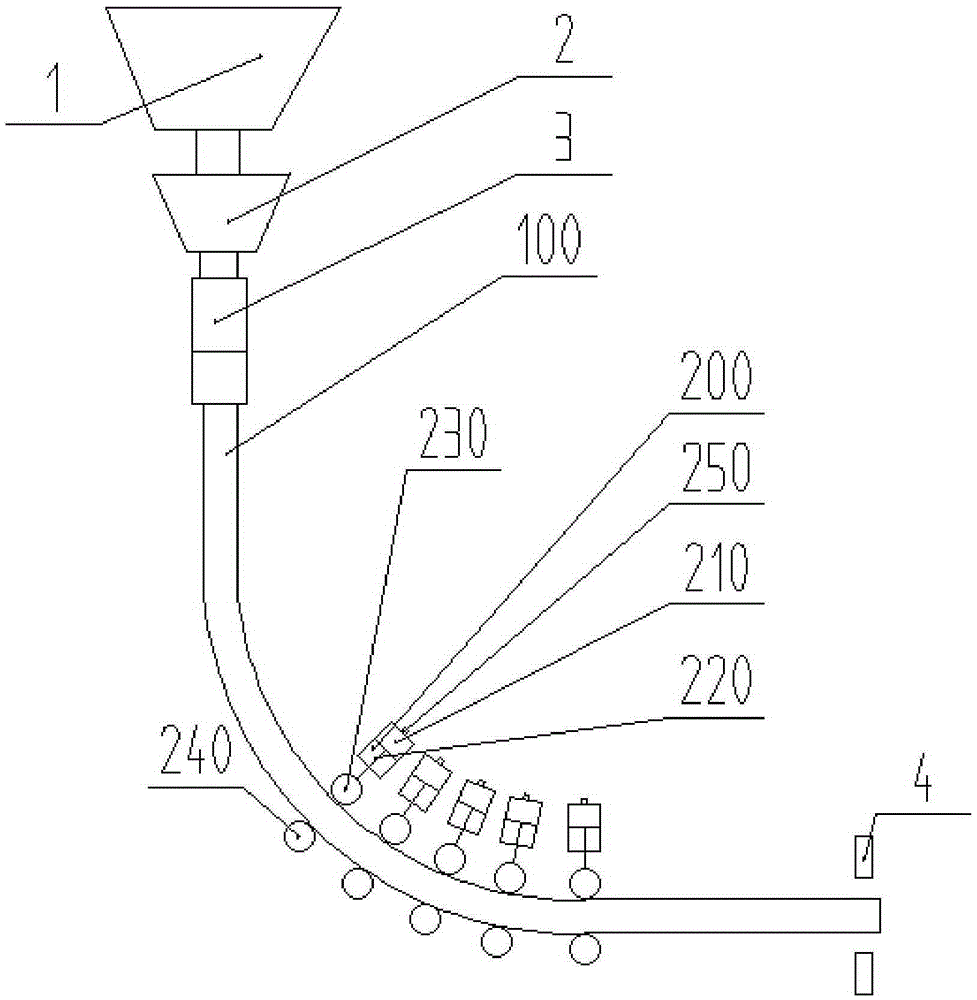

[0025] In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of one or more embodiments. It may be evident, however, that these embodiments may be practiced without these specific details. In other instances, well-known structures and devices are shown in block diagram form in order to facilitate describing one or more embodiments.

[0026] Various embodiments according to the present invention will be described in detail below with reference to the accompanying drawings.

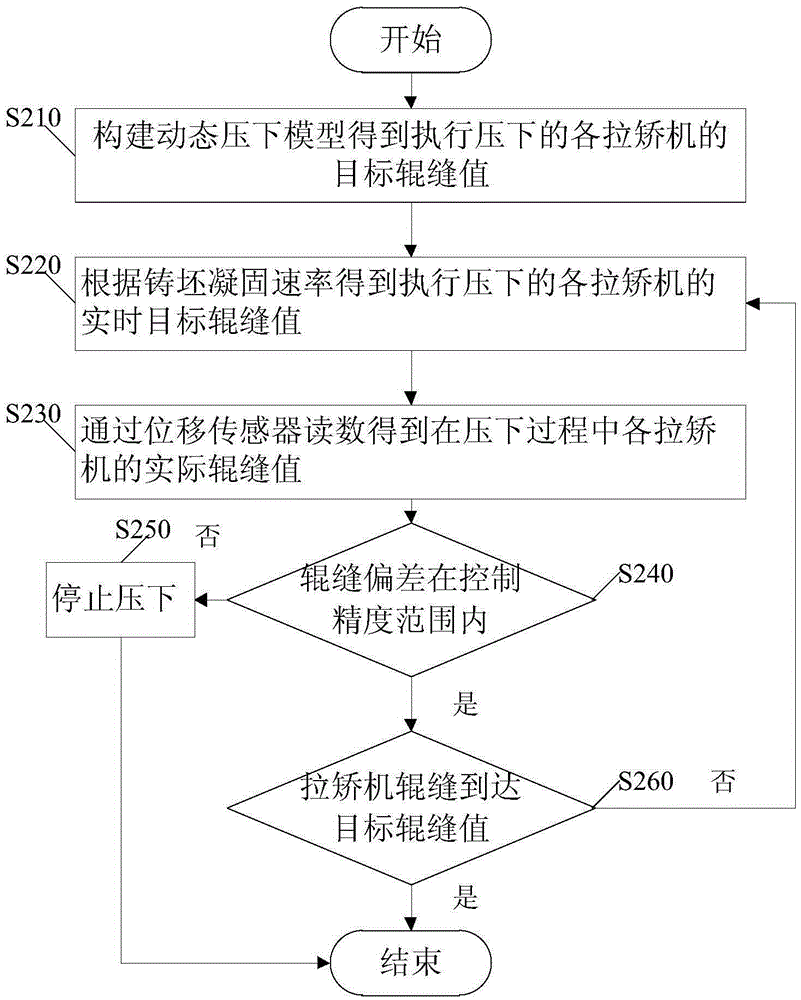

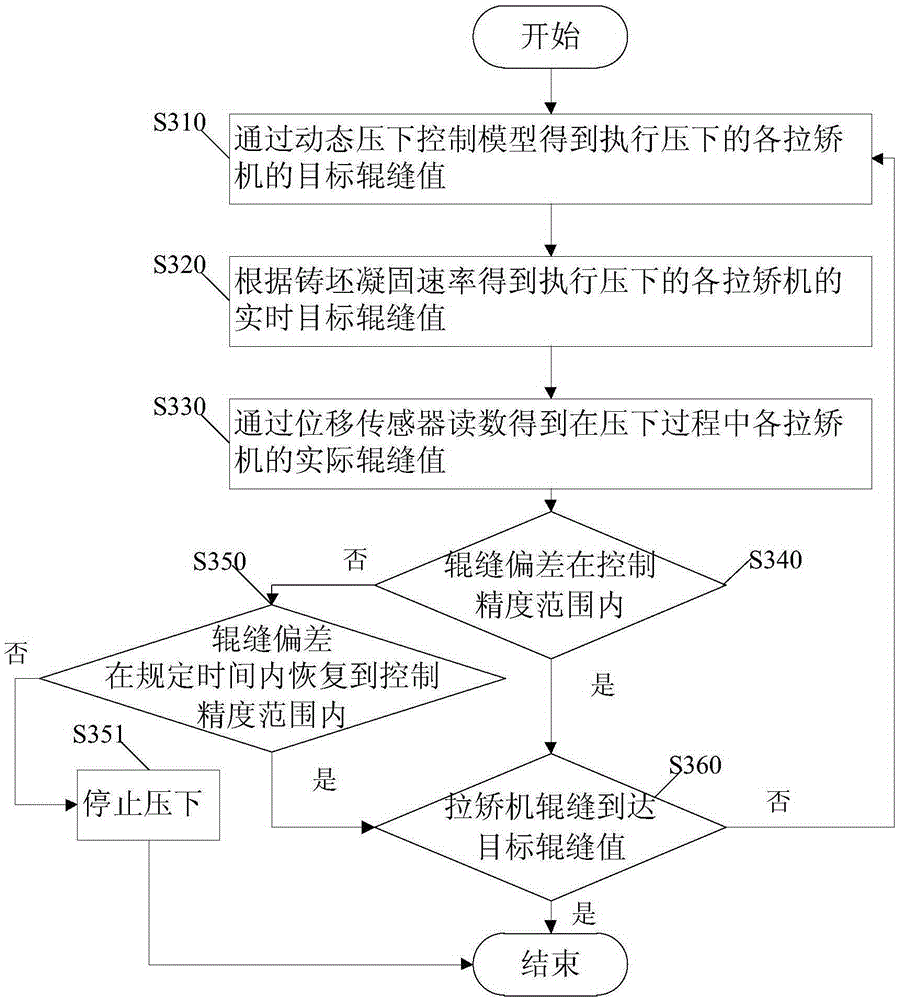

[0027] Fig. 2 shows a flow chart of an embodiment of the method for controlling roll gap deviation in the process of light reduction or heavy reduction in the present invention. Deviation control methods, including:

[0028] In step S210, a dynamic reduction control model is constructed, and the target roll gap value GAP of each tension leveling machine performing reduction is obtained according to the actual solidif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com