Top-mounted large-span platform automatic support mechanism

A technology of support mechanism and large span, applied in transportation and packaging, vehicle maintenance, lifting vehicle accessories, etc., can solve the problems affecting the stability of lateral support, the reliable and stable operation of the transportation work platform, etc., to ensure the stability of lateral support High mobility, high mobility, reasonable structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] For ease of understanding, the attached Figure 2-8 The specific implementation structure and work flow of the present invention are described as follows:

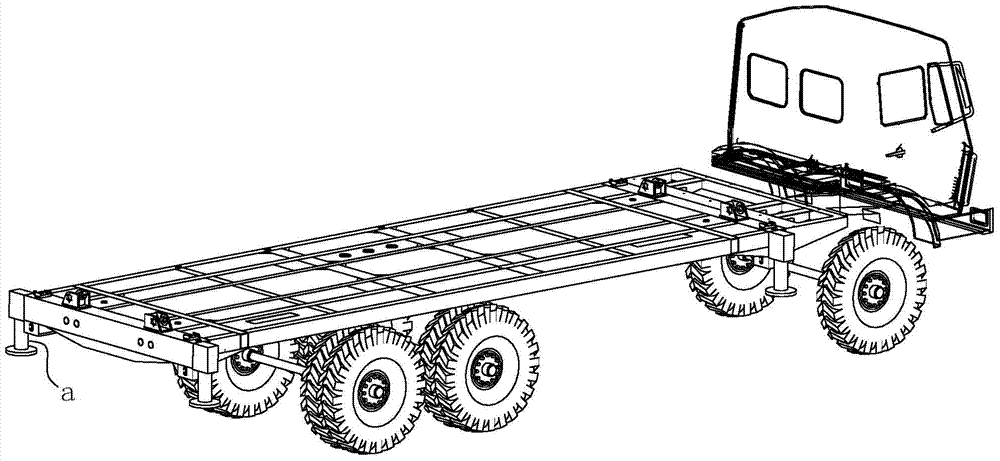

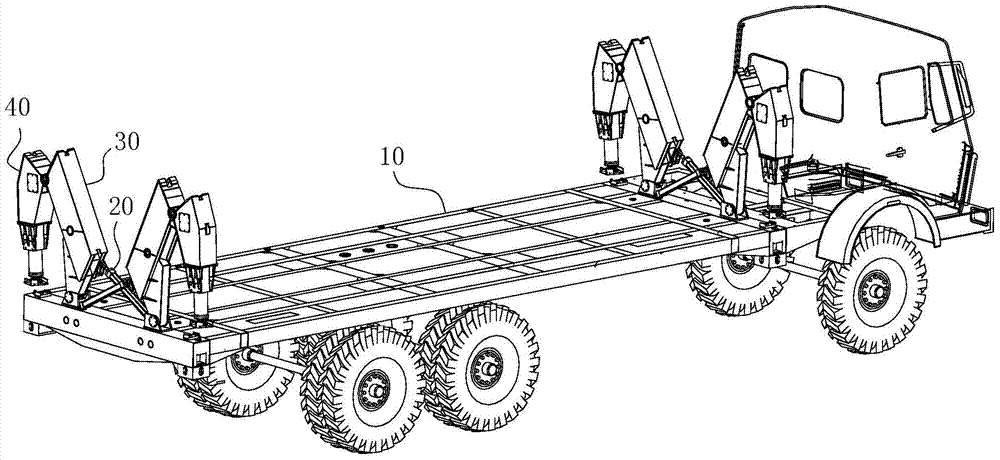

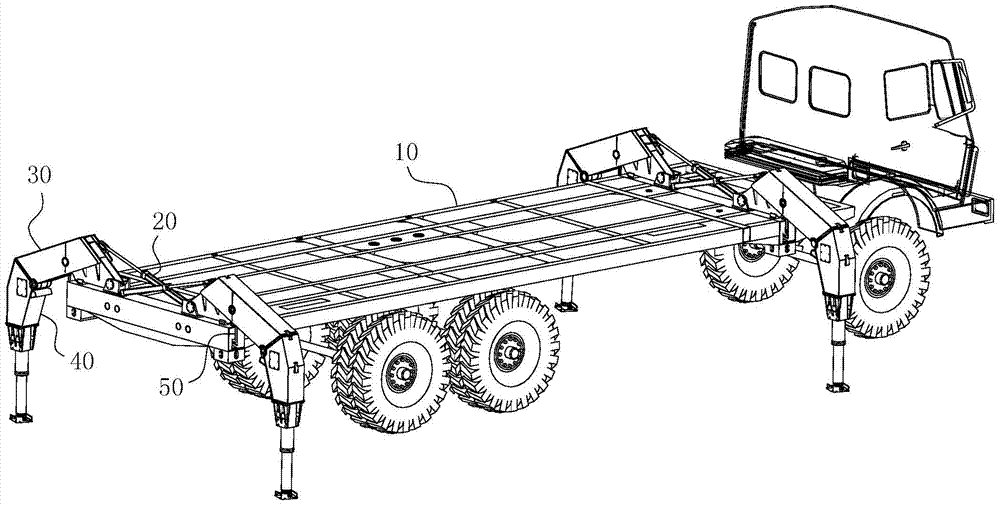

[0038] The state after the present invention completes assembly operation sees Figure 1-2 , by adopting 4 groups of supporting components to be respectively installed on the upper table places of the front, back, left, and right sides of the transport work platform 10 . Each support assembly is composed of an upper support arm 30, a lower support arm 40, a hydraulic power mechanism (that is, a hydraulic cylinder 20) and a follow-up locking mechanism 50, and an electric support composed of a screw nut mechanism is arranged in the lower support arm 40. leg. When working, the upper support arm 30 and the lower support arm 40 are pushed outward by the hydraulic power mechanism to realize the four-point supporting transport work platform. When the support components separated by two are in the support state, the late...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com